Astm Standards Explained

While browsing through the almost endless options for work boots or shoes, one of the terms you may have come across is the acronym ASTM, followed by varying number sequences. In this article, we’ll discover what this acronym means and why it’s an important aspect of work footwear (and other work gear).

What does ASTM mean?

ASTM (or ASTM International, as it’s currently known) stands for American Society for Testing and Materials. It’s an organization that’s focused on developing and publishing voluntary standards that are implemented in a wide range of industries and products- including work shoes and boots. These technical standards are composed of detailed material requirements and characteristics that are essential for quality and safe use.

ASTM Standards and their Importance

ASTM standards are developed by industry professionals (companies, individuals, and other organizations) forming committees that get together in a transparent process, with the goal of establishing and delivering the required test procedures, specifications, practices, and standards.

There are six types of ASTM standards, which are classified as:

- Specification – composed of a detailed set of provisions or requirements that a product, service, system, or material should meet.

- Test method – includes an informative description of a method that’s used in identifying the components of a product, material, or collection of materials.

- Classification – determines the provisions for methodically assigning systems, services, products, or materials into groups.

- Guide – composed of instructions or choices for specific situations but doesn’t recommend definitive action. Each guide is set to help the user in selecting the instruction or choice that best corresponds to a given situation.

- Practice – provides detailed instructions on how to best perform a specific operation or task.

- Terminology standards – these define and summarize terms, abbreviations, acronyms, and symbols that are used in a specific industry or field.

Protective footwear (also known as work boots or work shoes) is required for jobs and environments where control measures may not be enough to eliminate the risk of workplace hazards as assessed by the employers. ASTM standards detail the minimum requirements for delivering protection against different workplace dangers, such as:

- Rolling or falling objects

- Objects that can puncture the sole

- Electrocution hazards

- Rolling or falling objects

- Objects that can puncture the sole

- Electrocution hazards

According to the National Safety Council, statistics for the year 2020 indicated that there were 51,770 non-fatal injuries involving the lower extremities, resulting from contact with objects and equipment in the work area. While there’s no indication of the percentage of injured individuals not wearing the proper safety footwear, the sheer number of injuries, in itself, reinforces the need for protective footwear in various industries. ASTM standards set the bar high when it comes to minimum safety specifications with the goal of increasing workplace footwear safety, at the same time making the information more accessible to those who need it.

ASTM for Protective Footwear

ASTM F2413 is the specification standard that details the minimum performance requirements for foot protection in footwear with safety toe caps.

On the other hand, ASTM F2412 refers to the standard test methods that are used by scientists and researchers for protective footwear in laboratory settings.

Both standards are applicable for safety toe shoes (such as the Skechers Women’s Synergy – Sandlot Alloy Toe Work Shoe) and boots (such as the Timberland Hypercharge Composite Toe Boot).

Meanwhile, ASTM F2892 refers to the standard specification for performance requirements for non-safety footwear, or simply put – ASTM boots and shoes that don’t have safety toe caps (soft-toed protective footwear).

Understanding ASTM Standards and Symbols

ASTM standards can be quite confusing, so it’s a good idea to learn how to interpret them. First off, the two numbers that you usually see after the standard refer to the year that the standard was updated. For example, in 2018, ASTM F2413-18 replaced ASTM F2413-11 after the corresponding updates were set in place that year.

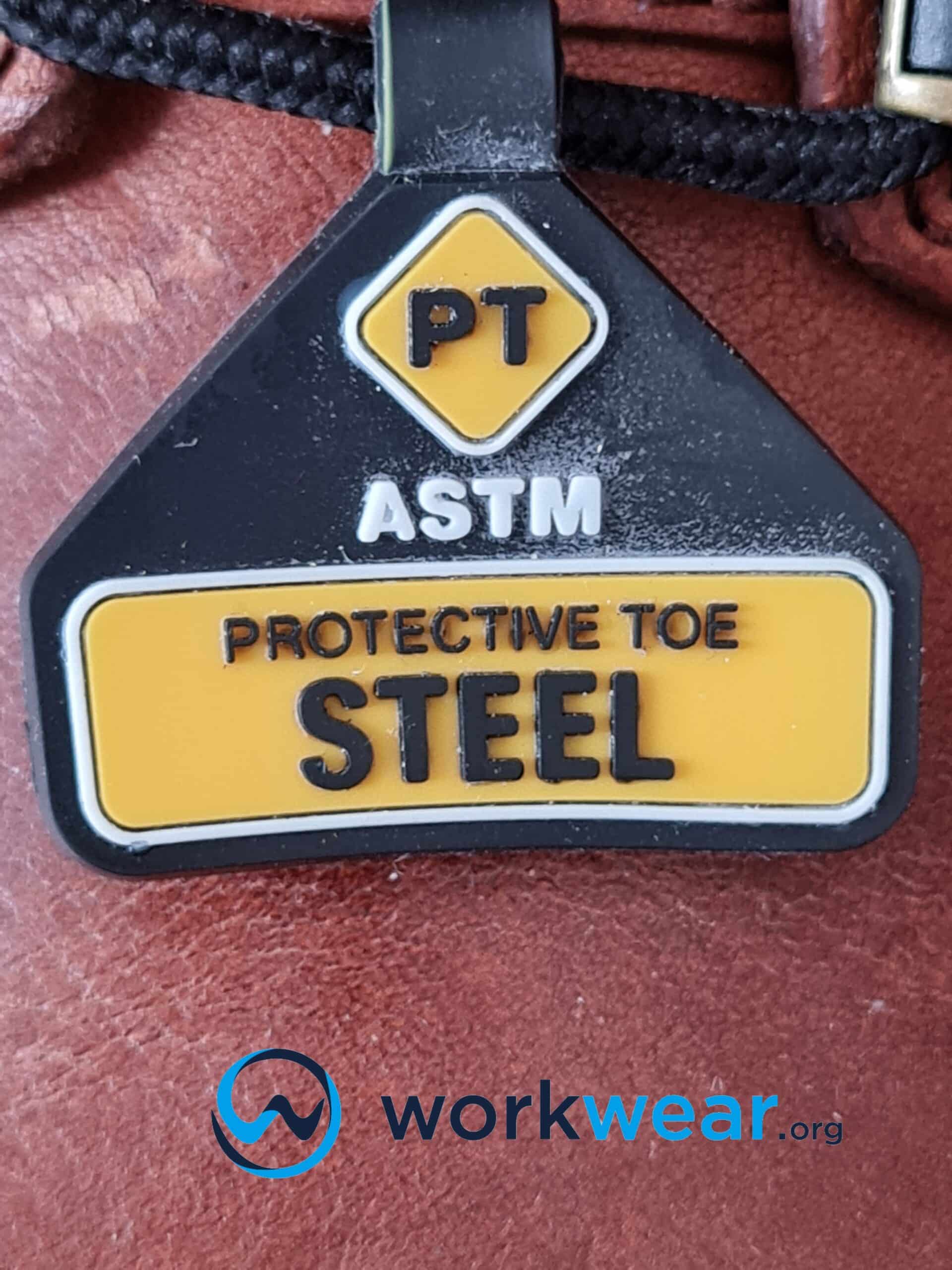

All safety shoes and safety boots that are manufactured to meet ASTM standards must have clear markings regarding the aspect with which it is compliant. Each shoe must have legible marks (by stamping, stitching, or using a label) on a specified portion, such as the surface of the gusset, tongue, quarter lining, or shaft.

The safety markings are required to be enclosed in a rectangular border following a four-line format when applicable. Line four is only used when the footwear has more than the protective features that can fit into three lines. Protective toe caps are required to have an identifying mark including the manufacturer’s name, logo, or trademark; they should also indicate the size and specify “R” or “L” (for right or left foot use) in a visible location. The same goes for metatarsal protection and puncture-resistant plates – they should have the manufacturer’s name or logo, identification or component number in a visible area.

Additional symbols that you may come across when using protective footwear are:

M = Footwear designed for a male

F = Footwear designed for a female

I = Impact resistance

C = Compression resistance

Before the ASTM F2413-18 update, compliance information on footwear labels used to have numbers next to “I” and “C” (such as “I/75” or “C/75”) to indicate the level of impact or compression resistance. With the implementation of changes in testing methods for the ASTM F2413-18 update, only the maximum levels of protection are required, eliminating the need to specify protection levels. Thus, “I” now indicates that the safety toe protects against the impact of a 75-pound force, while the “C” on ASTM F2413-18 safety shoes, for example, signifies a safety toe cap protection against compression of 2,500 pounds.

Mt = Metatarsal protection

Protection to the toes and metatarsal portion to protect against injuries if these parts are exposed to heavy falling objects. Just like for impact and compression, the metatarsal protection now denotes the highest level of 75 with the “Mt” indicator instead of the three different levels that were used prior to the ASTM F2413-18 update.

EH = Electrical hazard resistance

Footwear that’s built with an electric shock-resistant heel and sole. It’s designed to provide a secondary source of resistance against electrocution for the wearer in case of incidental contact with electrically charged materials or objects or live electrical circuits. It’s worth noting that EH-rated boots and shoes that are determined as such using ASTM electrical standards are only supplemental according to OSHA (Occupational Safety and Health Administration). Workers who are exposed to electrical hazards need primary sources of protection, as stated by OSHA standards.

SD or ESD = Static-dissipative properties

SD or ESD boots and shoes are built with enhanced soles that greatly minimize the risk of static electricity build-up. This protection has three levels, namely:

- SD 10 – electrical resistance range starting from 106ohms (1 megohm) up to 1.0 x 107ohms (10 megohms)

- SD 35 – electrical resistance range starting from 106ohms (1 megohm) up to 3.5 x 107ohms (35 megaohms)

- SD 100 – electrical resistance range starting from 106ohms (1 megohm) up to 108ohms (100 megohms)

Cd = Conductive properties

Designed to reduce static electricity to significantly minimize the possibility of volatile chemicals, explosive dust, and explosives in the surrounding area being ignited.

PR = Puncture resistance

The safety boot or shoe is fitted with a puncture-resistant plate that’s sandwiched between the insole and outsole. The enhancement helps prevent sharp objects from piercing the footwear from the bottom.

ASTM Ratings

ASTM F2413-18

ASTM F2413-18 is a standard encompassing footwear that’s built and manufactured with a safety toe cap permanently integrated into the structure. It includes requirements that specifically analyze the footwear’s performance for impact resistance and compression resistance.

Additional protection criteria, such as the ones below, can be met depending on the type and level of protection needed and will then be labeled appropriately.

- Electrical hazard protection

- Puncture resistance

- Metatarsal protection

- Conductive protection

- Static-dissipative protection

ASTM EH Rating

ASTM EH boots and shoes are built with non-conductive heels and soles to provide a non-primary source of protection against electric shock, with accidental exposure to open circuits or electrically energized materials, parts, or apparatus. These outsoles are designed to withstand exposure to up to 18,000 volts at 60 Hz for one minute in dry conditions.

What is ASTM F2413-11?

ASTM F2413-11 is the standard specification that comprises the minimum performance, classification, design, and testing requirements for protective toe cap footwear. It replaced the ANSI Z41 standard that was once defined as the performance standards for protective footwear but has since been withdrawn in 2005.

Footwear that’s compliant with ASTM F2413-11 (as well as the earlier ASTM F2413-05 boots version) standards should meet the following requirements:

- Toe area compression resistance

- Toe area impact resistance

Following compliance to impact and compression resistance, meeting the following protection requirements can then be done:

- Metatarsal protection

- Conductive properties to reduce static electricity accumulation and minimize the risk of igniting volatile chemicals and/or explosive substances

- Puncture resistance of the footwear’s bottom part

- Electric shock resistance

- Static dissipative properties to minimize the risk of extremely low-resistance footwear with SD qualities

- Chainsaw cut resistance

- Dielectric insulation

As noted earlier, ASTM F2413-11 has since been succeeded by ASTM F2413-18, with notable changes taking effect regarding the way information (such as impact resistance, compression resistance, and metatarsal protection) is indicated on the label.

ASTM F2413-11 vs ASTM F2413-18

Just like ASTM F2413-11, ASTM F2413-18 covers specifications that comprise the minimum performance, classification, design, and testing requirements for protective toe cap footwear – with the addition of some changes to the way information is indicated. ASTM F2413-18 standards also require a Certificate of Conformance (COC) that needs to be issued by a third-party laboratory.

An update to the specification standard was made in 2018 and was then called ASTM F2413-18. The update included a modification indicating that all footwear constructed to follow ASTM specifications must have the detailed markings displayed in an enclosed rectangular border following a four-line format where applicable. The markings should be displayed as follows:

Line 1 – indicates the compliance with ASTM F2413 standard

Line 2 – indicates the user’s gender (M/F) and the subsequent classifications for impact resistance (I), compression resistance (C), and metatarsal protection (Mt)

Lines 3 & 4 – indicate the other types of hazard protection that the footwear offers as referenced in the standard5.

|

ASTM F2413-1 |

ASTM F2413-18 |

|

|---|---|---|

| Specifications |

minimum performance, classification, design, and testing requirements for protective toe cap footwear |

minimum performance, classification, design, and testing requirements for protective toe cap footwearCertificate of Conformance (COC) requiredDetailed markings displayed in an enclosed rectangular border following a four-line format |

What is ASTM F2412-11?

ASTM F2412-11 refers to the standard test methods for Foot protection. It’s composed of test methodologies that measure the footwear’s resistance to different hazards that can have the potential to cause injuries. The areas that are covered by the test methods are:

- Impact resistance, specifically on the footwear’s toe area

- Compression resistance, specifically on the footwear’s toe area

- Metatarsal protection to minimize the risk of injury to the top of the foot’s metatarsal bones

- Electrical hazard protection (when stepping on live wires or electrically charged objects)

- Conductive properties to minimize the risk of static electricity accumulation, as well as the possibility of igniting volatile substances or explosives

- Static dissipative properties to minimize the risks that are associated with the footwear’s exceptionally low resistance to electricity, which may exist in areas that require SD footwear

- Puncture resistance

Soft Toe Protective Footwear

While it’s easy to assume that only footwear with safety toes can be considered protective, this isn’t the case as even soft-toed shoes and boots can be enhanced with protective features. Even electrical hazard protection, which is often regarded as exclusive to safety toe footwear, can also be maximized in specific ASTM-certified soft-toed footwear, such as the Reebok Sublite Cushion RB806 Women’s 8-Inch Tactical Waterproof Boot. ASTM F2892-11 refers to the standard specification for performance requirements for non-safety or non-protective toe footwear (also known as soft-toed shoes or boots). The specification standards indicate performance requirements to keep the users’ feet (aside from the toe area) protected from safety hazards by providing:

- Conductive properties to minimize safety hazards that may be caused by the accumulation of static electricity, and to reduce the risk of igniting volatile substances and explosives

- Static-dissipative properties to minimize that safety risks are associated with the footwear’s exceptionally low resistance to electricity, which may exist in areas that require SD footwear

- Electrical hazard protection to keep the user safe in case of unintentional stepping on electrically charged components

- Puncture resistance

A more recently updated version, the ASTM F2892-18 for soft toe protective boots and shoes, now follows the same three static-dissipative (SD) levels that are used for ASTM F2413-18 safety toe protective footwear standards. Similarly, ASTM F2892-18 requires a Certificate of Conformance and the same labeling requirements as indicated by ASTM F2413-18 specifications. This version also introduced improved performance data and testing. The improved standard followed the internationally established principles of standardization issued by the World Trade Organization Technical Barriers to Trade Committee, through its Decision on Principles for the Development of International Standards, Guides, and Recommendations.

ASTM Slip-Resistance Testing

Aside from the previously discussed standards for hazard protection that are delivered by ASTM shoes & boots, there are also slip-resistance test methods in place. ASTM F2913-19 is the specific test method that’s used to evaluate the dynamic coefficient of friction between footwear and different surface conditions as indicated by set laboratory conditions, with the purpose of determining slip resistance function. The test method is applicable to all footwear types, outsole structures, and sole materials, as well as to most flooring types. It also takes into account various contaminants in surface conditions, including ice, liquid water, grease, and oil.

It should be noted that while ASTM F2913 is currently considered the gold standard for establishing the dynamic coefficient of friction (COF), there’s still no defined safety threshold for analyzing footwear’s slip resistance. However, the whole shoe test used in ASTM F2913 is still the most comprehensive approach to determining how various footwear materials perform with different surfaces (along with the contaminants, where applicable).

Slip resistance scores used to be generated using the Mark II Brungraber (or ASTM F1677), but this was eventually withdrawn in 2006 by ASTM because the measurement only used a section of the outsole, as opposed to testing the entire shoe.

Conclusion

ASTM standards are set in place to provide a specified minimum set of requirements that personal protective equipment – or in this case, footwear – should have, in order to maintain the highest standards of safety in different work environments. With the safety specifications clearly marked in ASTM-rated boots and shoes, it becomes easier for employers and wearers to determine which products should be chosen to correspond to their existing work conditions with enhanced safety in mind. By using ASTM-compliant protective footwear, you can significantly increase safety in the workplace and avoid life-changing injuries, especially on hazardous job sites.

FAQs

- Do all ASTM shoes have a steel toe cap?

- No – there are ASTM safety toe shoes and boots that can have alloy toe caps (such as the Timberland PRO Women’s Titan 6-Inch Alloy Toe Waterproof Work Boot), as well as toe enhancements that are made with nonmetallic (composite) materials, such as carbon fiber (used in the Wolverine Jetstream CarbonMAX Work Shoe) or Kevlar. There are also ASTM-rated protective footwear options that don’t have safety toe caps and instead have soft toes, such as the Danner Bull Run Moc Toe Boot.

- Is ASTM F2413-18 OSHA approved?

- Yes, OSHA approves and follows ASTM standards and procedures.

- Are ASTM standards applicable to boots and shoes?

- Yes. ASTM F2413 is the specification standard detailing the minimum performance requirements for foot protection in safety toe boots and shoes. Meanwhile, ASTM F2892 refers to the standard specification for performance requirements for soft toe ASTM boots and shoes.

- Are there ASTM slip-resistant shoes?

- No – ASTM only has a testing method in place to determine the coefficient of friction to give an idea of how the footwear will perform on specific floor conditions and with contaminants (such as water or grease) in place. However, there’s still no specific safety threshold in place for analyzing footwear’s slip resistance

References

ASTM International – https://www.astm.org/

National Safety Council – https://injuryfacts.nsc.org/work/safety-topics/contact-with-objects-and-equipment/data-details/

Research Gate – https://www.researchgate.net/publication/262685839_Footwear_Use_at_Workplace_and Recommendations_for_the_Improvement_of_its_Functionality_and_Hygiene

OSHA (Occupational Safety and Health Administration) – https://www.ccohs.ca/oshanswers/prevention/ppe/foot_com.html

Western Carolina University – https://www.wcu.edu/discover/campus-services-and-operations/facilities-management/safety-and-risk-management/occupational-safety-and-health/foot-protection.aspx

678+

Products Reviewed

24+ Years

Combined Experience

500+ Hrs

Field Testing