TPU Uses in Work Boots

Work boots and work shoes use various materials for different sections. Each type of material brings its own merits to enhance the footwear’s overall performance and, sometimes, appearance. Most focus is on leather and fabric materials used for work footwear, but there’s also TPU to consider.

TPU is used in different work boots and shoes sections, which can work as a standalone component or be used with other materials.

In this article, we’ll learn more about the qualities of TPU and address some misconceptions about the material’s use in work footwear.

What is TPU?

TPU stands for “thermoplastic polyurethane” – a category of plastic used for parts of work boots and shoes and many other applications, including medical devices, sporting goods, and cable casings.

It has rubber and plastic qualities, exhibiting reliable durability and adaptability that can be maximized in various products across different industries.

TPU has a high level of resistance to abrasion and scratches, making it suitable for uppers and other high-wear areas in footwear.

It’s also breathable and flexible, which is why it’s often used in sports footwear and work boots and shoes with athletic styles.

TPU and Safety Toes

There’s a common misconception about TPU in work boots that come from non-reliable sources – which can add to the confusion regarding this material.

The information from non-expert sources states that TPU is a main material for safety toe caps, but this isn’t the case.

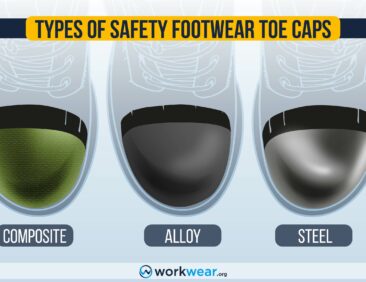

In reality, only steel, alloy, and composite (Kevlar or carbon fiber) materials are used as the main materials for safety toe caps.

On the other hand, TPU is used as a coating material for some steel or composite toe caps, which are then fitted into safety work boots.

To sum things up, TPU isn’t the primary main protective material but instead acts as a protective coating for the toe caps.

It provides an extra layer of abrasion resistance that can help prolong the quality and performance of safety toe caps inside work boots and shoes.

Uses of TPU in Work Boots

Now that we’ve established that TPU isn’t used only for coating (and not as the primary material) for safety toe caps let’s discuss the other footwear sections that use TPU.

TPU Upper

Work boots can include sections of TPU in their uppers. This is especially true for work boots made with non-leather or pleather uppers, often with styles that look more like sports sneakers.

The TPU sections in the upper are typically combined with materials such as polyester or mesh to deliver superior performance. We got to experience this remarkable combination of TPU and mesh when we used the highly rated Wolverine Jetstream CarbonMAX Safety Toe Shoe, which we had a chance to review in different work scenarios.

Key Advantages of TPU Upper Sections

Lightweight

Work boot uppers with TPU sections are lightweight, especially when combined with polyester or mesh components.

The TPU sections offer additional protection for the feet but don’t feel too weighty, so the work boots and shoes are much lighter than those with thick leather uppers.

Abrasion-resistant

TPU is abrasion-resistant, so uppers with this material incorporated into the structure don’t get scratched easily.

The material prevents premature wear with heavy footwear use, especially in conditions exposed to abrasion hazards.

Breathable

TPU is a breathable material. Combined with other synthetic materials, TPU makes the upper more welcoming to plenty of air.

This quality keeps the feet feeling fresh for much longer as the air is allowed to flow unhampered inside the work boots or shoes.

Flexible

TPU is flexible and doesn’t restrict the foot’s motion when fitted into the footwear’s upper.

Sporty work boots with TPU in the upper flex along with each step, so walking is much easier without rigid materials that can hinder natural motion.

Resistant to oil, grease, and stains

TPU has a strong resistance to oil and grease, so these substances won’t easily penetrate work boot uppers with TPU sections.

This attribute is exceptionally helpful for job environments regularly exposed to grease and oil-based products.

Water-resistant

TPU sections make the upper more resistant to liquid penetration.

While the material isn’t fully waterproof, it still offers a barrier to protect the feet against becoming soaked in case of accidental spills of water and other liquids.

Resistant to staining

TPU doesn’t easily absorb liquids which may cause staining.

The material allows liquids to slide off instead of penetrating, significantly reducing the risk of unsightly stains forming on the work boots’ or work shoes’ uppers.

Key Disadvantages of TPU Upper Sections

Do not mold to the foot’s shape

TPU doesn’t conform to the foot’s contours like leather does.

While flexible enough to move with each step, TPU sections don’t give the uppers the customized fit that leather offers for long-term use.

May look too informal

TPU sections are often included in work boots or shoes with sporty profiles.

This typically results in a casual profile that can be inappropriate for indoor offices and other formal work environments.

Uses of Work Boots with TPU Sections in the Uppers

Work boots with TPU in the upper are ideal for prolonged periods of walking in challenging or hot environments, such as the conditions experienced by the following jobs:

- Auto mechanics

- Warehouse personnel

- Food service staff

- Cooks and chefs

| TPU Sections in the Upper |

Pros |

Cons |

|---|---|---|

| TPU Outsoles |

|

|

TPU Shank

A shank is a material placed between the outsole and insole of shoes and boots.

It works to maintain the footwear’s structural integrity while keeping the foot fully supported for a stable experience while walking.

Safety boots and shoes can be fitted with steel shanks for increased support, but some are built with TPU shanks instead.

Work shoes and work boots with TPU shanks – such as the Under Armour Stellar Tactical Boot – typically feel flexible and lightweight, making them great options for all-day walking or standing in variable ground conditions.

Key Advantages of TPU Shanks

Lighter than steel

TPU shanks are much lighter compared to steel shanks. They don’t contribute a lot of bulk, so work boots and shoes with these fitted in can maintain their reduced weight profiles more easily.

The lightweight structure of TPU shanks makes boots and shoes comfier to wear for hours of walking and standing.

Support the feet for better stability

TPU shanks deliver extra rigidity to the arch or midfoot areas (depending on the shanks’ design). The additional support keeps the feet in proper alignment and allows them to move naturally without compromising efficiency and stability.

This is especially helpful when working in work areas with unstable or sloped ground conditions.

Stronger resistance to oil and chemicals

TPU is more resistant to oil and chemicals than steel.

When these substances penetrate the boot and reach the midsole, TPU shanks are less vulnerable to damage than steel shanks.

More flexibility

While TPU shanks make the boots more stable, they can flex just enough to follow the feet’s motion easily.

The result is reliable support from the bottom of the work boots, with the flexibility to support the feet’s natural agility.

Typically, more affordable than steel shanks

TPU shanks are generally less pricy than steel shanks.

While these components are not the main factors for work boots and shoes’ prices, they still contribute to the overall price point and can influence the total cost.

Do not trigger metal sensors

Unlike steel shanks that can trip metal detectors, TPU shanks have no metal parts, so they won’t accidentally trigger metal sensors to go off.

This makes work boots and shoes with TPU shanks ideal for jobs close to metal detectors.

Key Disadvantages of TPU Shanks

Less durable than steel shanks

TPU have a high resistance to abrasion and chemicals, but steel is still more durable.

Steel shanks’ solid build and strength tend to resist damage better than much lighter TPU components.

Uses of TPU Shanks

Work boots and shoes with TPU shanks are suitable for professions that involve walking or standing for extended periods (including on unstable surfaces), which the following jobs can encounter:

- Delivery personnel

- Linemen

- Carpenters

- Plumbers

|

Pros |

Cons |

|

|---|---|---|

| TPU Shanks |

|

|

TPU Outsole

Rubber isn’t the only material used for high-quality work boots and shoes. However, TPU has the flexibility and durability qualities crucial for work footwear – with the added benefit of a minimized weight structure.

Work boots with TPU outsoles, an example of which is the Redback Bobcat Chelsea Boot, are often grippy enough to prevent slipping on tricky surfaces.

The outsoles feel flexible and easily accommodate the feet’s motion but don’t have the severely weighty feel that thick rubber soles tend to exhibit.

Key Advantages of TPU Outsoles

Lightweight

TPU is generally more lightweight than rubber.

TPU outsoles aren’t as bulky as rubber, so the boots and shoes are suitable for prolonged walking or standing.

They don’t drag on the feet with extreme weight, preventing a tired feeling from setting into leg and foot muscles.

Flexible, even in cold conditions

TPU outsoles are flexible and enable the feet to move naturally while walking.

They maintain this flexibility even in low-temperature work environments (unlike other outsole materials), so ease of motion can still be enjoyed in such challenging settings.

More resistant to cracking or splitting

The flexibility of TPU outsoles makes them more resilient against splitting or cracking.

Even with heavy use in extreme conditions, TPU outsoles can flex along with the feet’s motion for more efficient movements and resistance against damage.

Abrasion resistant

The strong abrasion resistance of TPU works to protect outsoles against premature damage. TPU outsoles maintain their high-quality appearance and functionality for a long, even when the work boots or shoes are used in tough conditions.

This resistance to abrasion prolongs the footwear’s quality and lasting benefits.

Strong traction

TPU outsoles strongly grip different surfaces.

They’re not as bulky as rubber outsoles and often don’t have the same heavy-duty structures, but TPU outsoles can firmly grip the ground. This quality helps prevent slipping on slick, rough, or uneven surfaces in the work area.

Oil and grease resistant

Work boot outsoles made with TPU highly resist grease and oil.

TPU outsoles don’t absorb these substances, which may be present in challenging work environments.

As a result, the outsoles maintain superior performance without being negatively affected by exposure to such harsh elements.

Key Disadvantages of TPU Outsoles

Low resistance to heat

In general, TPU doesn’t have a high resistance to heat. So, unlike other materials – such as rubber or nitrile – that remain resilient, TPU can easily show signs of damage when exposed to hot surfaces.

This makes work boots with TPU outsoles unsuitable for working on high-temperature surfaces, such as asphalt.

Can deteriorate in storage

TPU outsoles deteriorate when left in storage for a long time.

They can discolor and deteriorate quickly when they are not used for extended periods and are just kept in storage.

Uses of TPU Outsoles

TPU outsoles are ideal for professions requiring continuous standing or walking that may need to be done in cold or slippery settings, such as the ones where these jobs are performed:

- Farmers

- Landscape workers

- Law enforcement officers

- Road maintenance workers

|

Pros |

Cons |

|

|---|---|---|

| TPU Outsoles |

|

|

Conclusion

TPU or thermoplastic polyurethane, is a type of plastic that exhibits the best qualities of rubber and plastic. The material is used in various applications, including specific components in work footwear. It should be noted that TPU is mistakenly claimed to be a primary material for safety toe caps but is used to coat the protective toe components. TPU showcases numerous benefits in other sections of work boots and work shoes, though. The resilient, flexible, and lightweight material fits into upper sections and is a main material for supportive shanks and grippy outsoles. TPU’s numerous merits can be maximized in how the components are built into work boots and shoes, allowing them to perform remarkably well in different work environments.

FAQs

- Why are TPU outsoles suitable for cold work areas?

- TPU outsoles don’t harden when exposed to low temperatures. They remain flexible and allow the feet to move naturally, so foot movement isn’t compromised in cold work conditions.

- What makes TPU outsoles better than PU ones?

- TPU has a higher level of abrasion resistance compared to PU. While both materials are lightweight and flexible, TPU is sturdier and more durable – so it’s expected to perform well for much longer than PU.

- Can TPU be added to the upper of leather boots?

- Yes, TPU can be included in the upper of leather boots. An example is the Under Armour Micro G Valsetz Leather Waterproof Tactical Boot which has a full-grain leather upper featuring an exterior TPU toe cap (or scuff cap).

- What makes TPU shanks more comfortable than steel shanks?

- TPU shanks are sturdy yet flexible, so they can support and stabilize the feet in position while allowing ease of motion at the same time. The flexible nature of TPU shanks is absent in steel shanks – which can be too rigid and hinder the feet’ natural, comfortable movements.

678+

Products Reviewed

24+ Years

Combined Experience

500+ Hrs

Field Testing