Boots Terminology – All Boots parts explained & illustrated

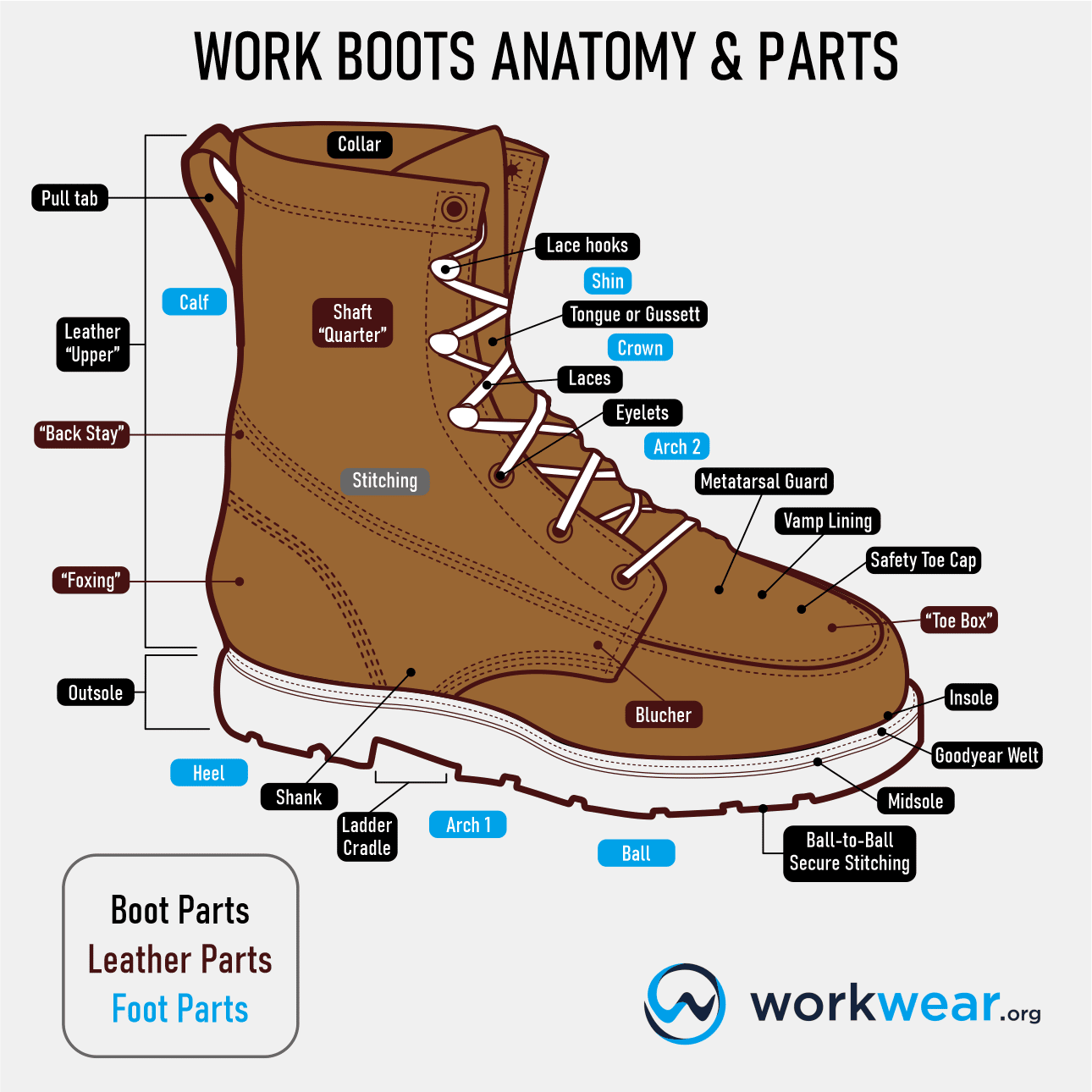

Your boots are essential in your daily life, especially if you use them for work. Depending on the materials and construction, they can also keep your feet safe from the elements and other hazards. However, when you read articles about boots, chances are, you’ll come across unfamiliar terms describing boot and work boot parts. To help clear things out, we’ve listed the most important parts of boots and each part’s corresponding terminology. Our goal is to demystify the jargon used for the parts of boots and work boots, so you can more fully appreciate their meanings and how each component works to enhance the footwear’s performance. Becoming familiar with these terms can also help you sift through the vast array of work boot choices, so you’ll end up with the pair that best suits your preferences and needs.

Key Takeaways

- The terms used for the parts of work boots can be confusing, especially the ones that aren’t commonly used.

- When categorizing the components of work boots, boot parts refer to the ones that make up the footwear’s main structure.

- Leather parts are the ones that are crafted from leather or are attached to the material throughout the boots.

- It’s also good to know which parts of the foot are protected and supported by which boot components to appreciate their features and design better.

- Becoming familiar with the terminologies used for work boot parts can make it easier to choose the best footwear option that can bring maximum benefits, considering your job’s needs and personal comfort preference.

Boot Parts

These are the parts that make up the boot’s structural base.

Shaft

The shaft refers to the upper part of the boot that looks cylindrical and includes the opening. Depending on the boot’s height, the shaft can extend to the ankle, just past it, or almost up to the knee. The shaft height is calculated by running a measuring tape from the top of the sole to the opening at the top of the boot. The shaft protects the ankle and calf areas while still allowing natural movement, so this component needs to have a proper fit.

Toe Box

The toe box is the part that touches the toes when the boots are worn. This component is built to be extra tough to protect the toes from harm and because it’s often the first part of the boot that gets scratched or scuffed because of its location. The toe box can be fitted with a reinforced section (made from rubber or other materials) on the exterior that offers protection against abrasion and other forms of damage. In safety work boots, the toe boxes are reinforced with safety toe caps made with steel or composite materials, protecting the toes against heavy falling objects.

Safety Toe Cap

A safety toe cap is fitted into the toe box to protect the toes against dangerous impact and compression. The toe caps can be built with metal (such as steel or aluminum alloy) or non-metal materials, such as carbon fiber or fiberglass.

Regardless of the material used, safety toe caps significantly increase work boots’ protective qualities, especially when used in hazardous environments.

Metatarsal Guard

A metatarsal guard is built externally or internally into the top portion of the boot for enhanced foot protection against hazardous impact or compression. Unlike safety toe caps that only protect the toe area, metatarsal guards extend the protection on top of the boots where the metatarsal bones are, all the way to the ankle portion. These safety components can be made from metal (such as aluminum or steel) but can also be created using synthetic or nonmetallic materials.

Foxing

The foxing refers to the strip of material (usual rubber) as an exterior wall to strengthen the bond between the upper and the sole. It’s typically vulcanized, with the material overlapping the upper and running around the entire boot.

Backstay (Heel Counter)

The backstay is found at the back of the heel area. Also called a heel counter, this part is made with the same material as the upper but is often reinforced to create a more rigid structure. This extra rigidity keeps the heel secured to prevent the foot from sliding or shifting from its position, delivering improved stability while walking.

Leather Parts

The boot parts are typically crafted out of leather (or are directly attached to leather materials), and their functions are discussed below.

Upper

The upper is the front part of the boot that covers the top of the foot. As a result, the part of the boot takes up the most space. The upper can be constructed from leather and other materials (such as nylon or mesh) and, depending on the construction, can be composed of smaller parts that are stitched together to create the shape of the boot.

The upper forms a protective layer over the foot, shielding it from the elements and safety hazards. It also has the greatest impact on the boot’s aesthetics as it can come in various colors, textures, and even accents that can set them apart from other footwear styles.

Collar

The collar refers to the cuff around the boot’s opening. It’s often padded to cushion the ankle, protecting it from rubbing painfully against the upper’s interior while walking. The padded collar also helps secure the ankle to reduce the risk of twisting, especially while going over unstable ground. In addition, the collar’s padding material can provide additional insulation against the cold for a more comfortable experience.

However, if the padding on this area is too thick, it can make the boot feel uncomfortably bulky.

Laces

Laces are integral parts of the boots’ fastening system. They tighten or loosen the boots to fit comfortably over the feet. Laces also help secure the boots, preventing them from sliding unintentionally to promote increased stability while walking.

They can be made from different materials, including leather, but the ones that typically last the longest are made with woven nylon or Kevlar.

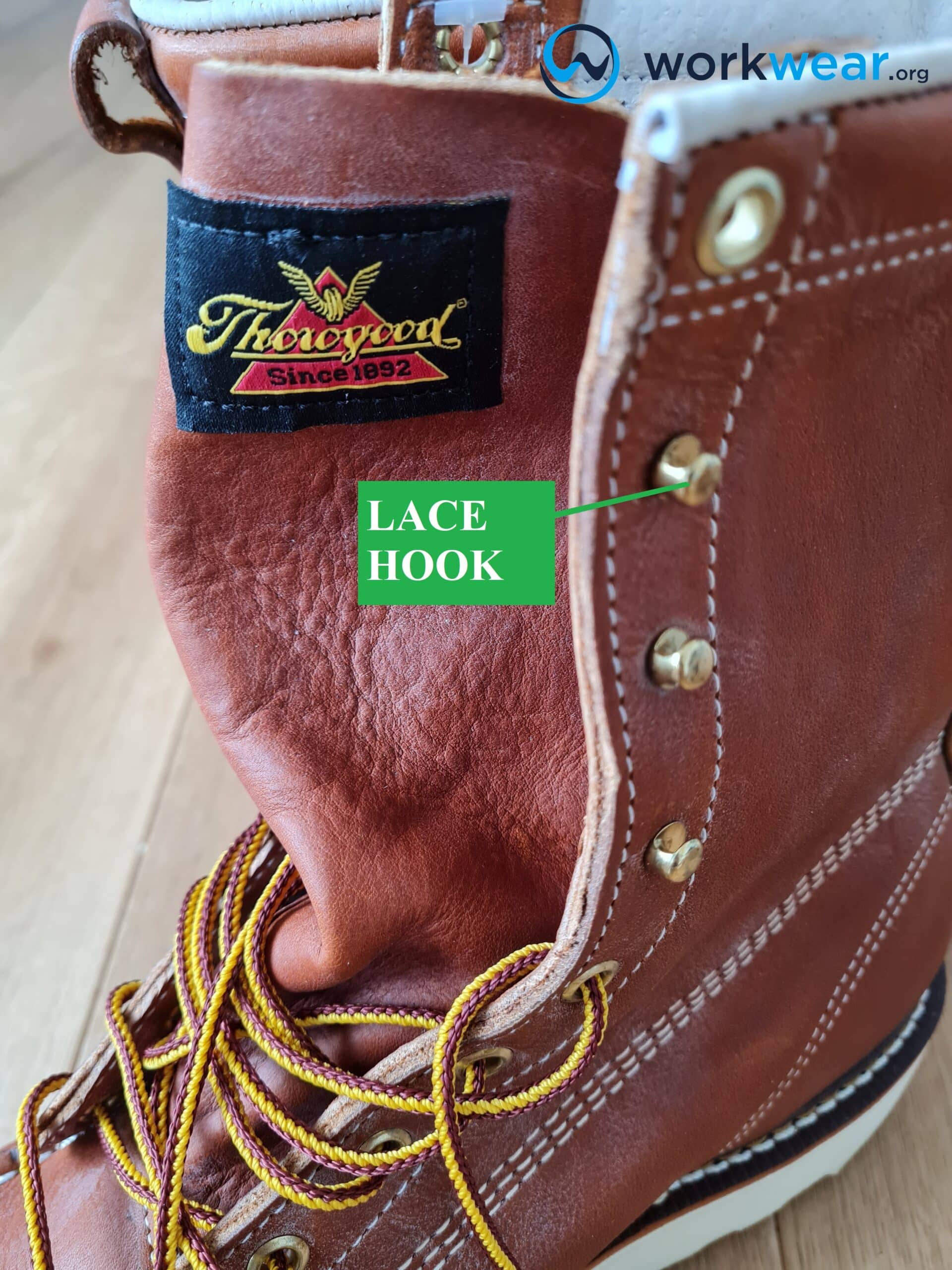

Lace Hooks

Lace hooks are often used with eyelets as part of the boots’ lacing system. Also referred to as speed hooks, they make boot lacing much faster as the laces don’t need to be threaded through the eyelets. Instead, the laces are wrapped around the lace hooks for a speedier way of securing the boots’ comfortable fit. Lace hooks are often made with the same material used with eyelets.

Eyelets

The eyelets are located on the top front part of the boots. These holes are where the laces are threaded through so the boots can be tightened or loosened to achieve a properly secure and comfortable fit. The eyelets can be made with metal or hard plastic, which are strong enough to accommodate the laces’ movements without easily getting damaged.

Eyestay

This is the part of the boot where the eyelets are built-in, and the laces go through. It’s typically made with the same material as the rest of the upper. However, some boots feature a reinforcing material on this part to make it stronger to support the eyelets and boot laces more efficiently.

Tongue

The tongue covers the top of the foot and ankle, protecting these parts from chafing against the boot’s interior. It also works to stop debris from getting in, especially if it’s stitched into the boot’s body on the base and on the sides.

A tongue permanently attached to the boot on the bottom and sides is referred to as a gusseted or bellows tongue.

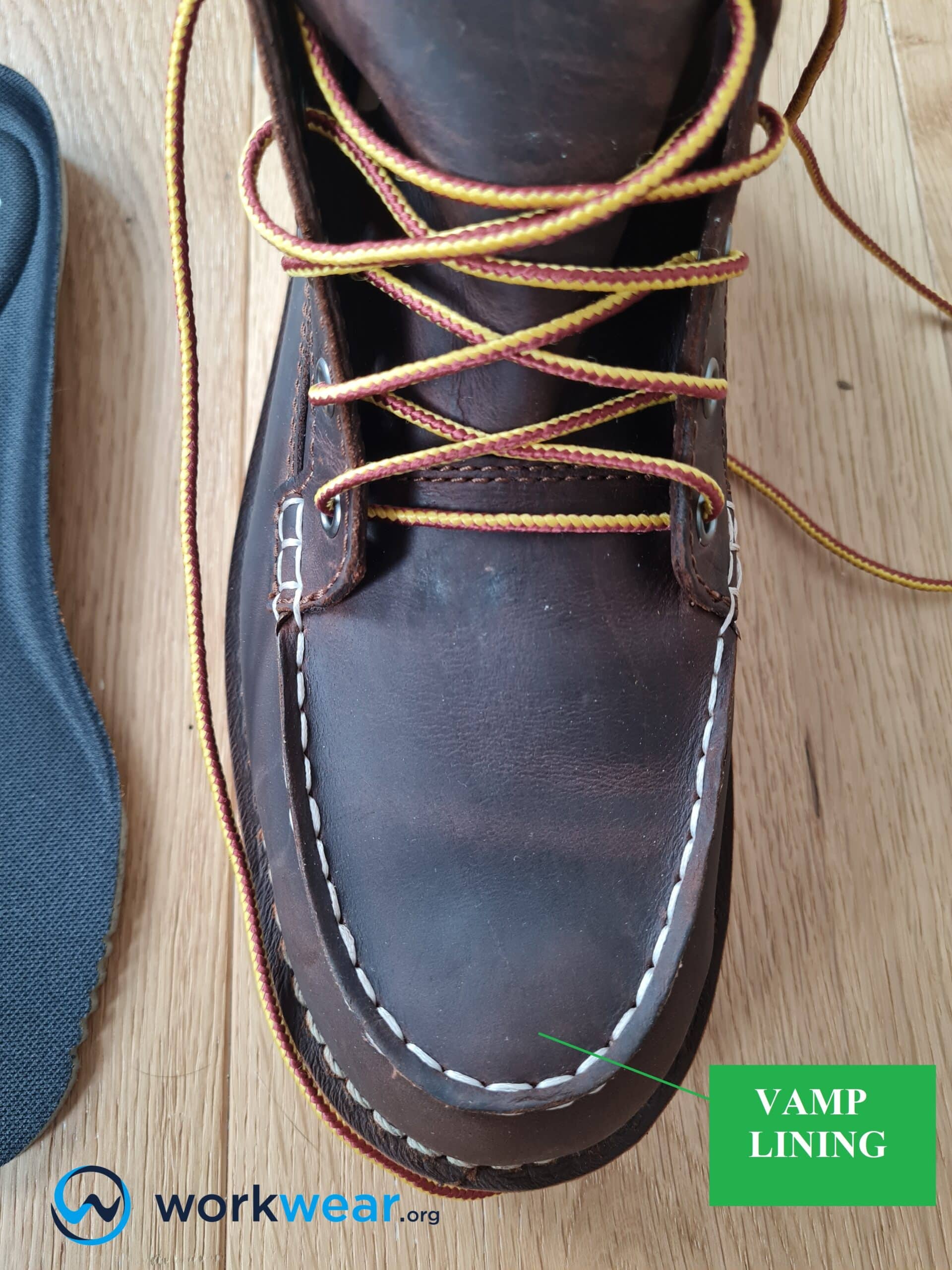

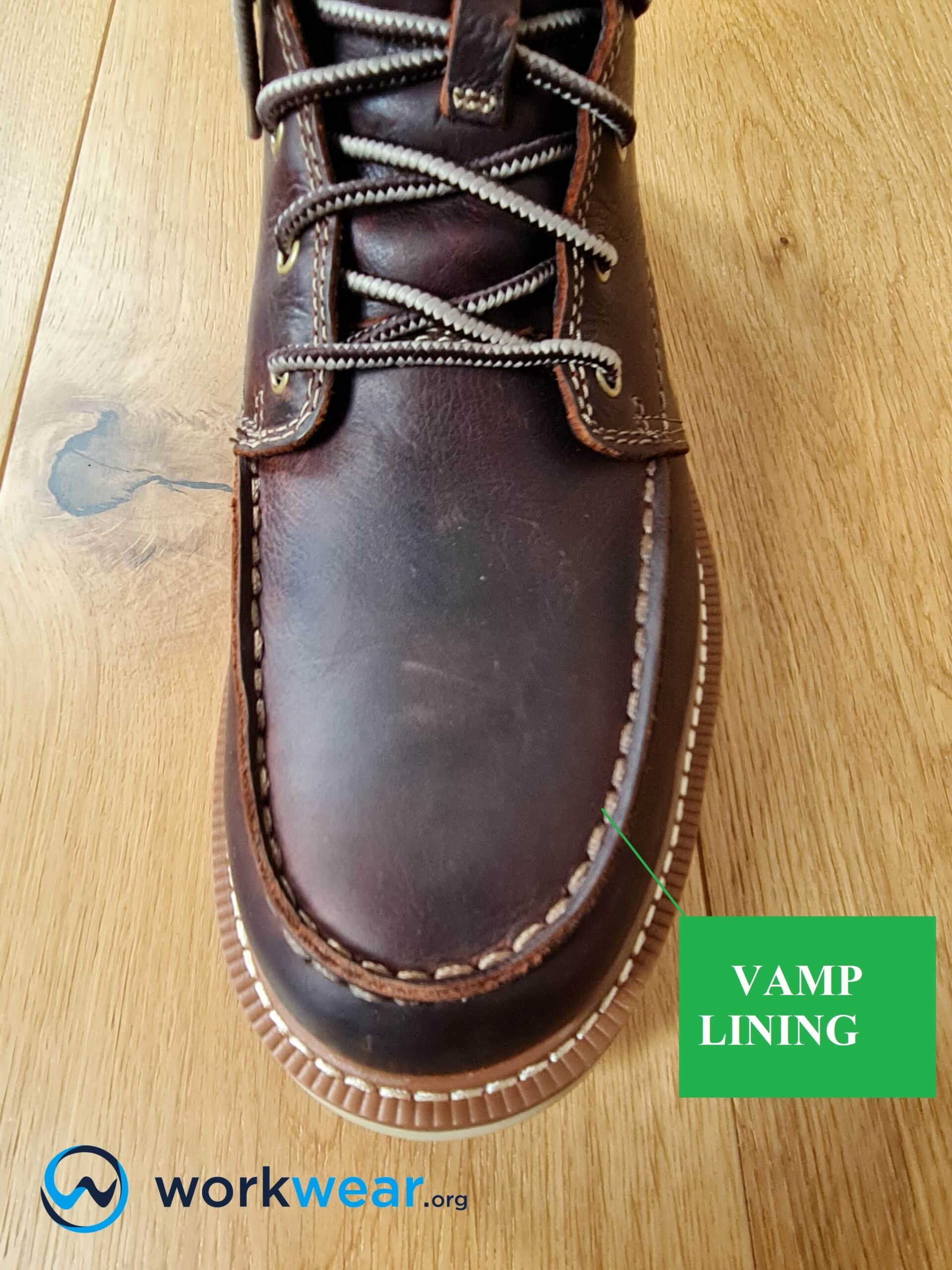

Vamp

The vamp is the part of the boot that covers the top of the foot and is the portion that’s visible if your pants cover the boot’s shaft. The vamp can be made from a single layer of material, although there are boots that come with a double layer. In boots with embellishments, the accents are typically found on the vamp.

Vamp Lining

The vamp lining refers to the material that protects the top part of the boot, which is called the vamp. This lining can be built with the same material used on the rest of the boot’s upper, but some are made with other materials (such as breathable mesh) for increased flexibility and comfort.

Insole

The insole is the bottom layer that touches the foot’s sole inside the boot.

It provides much-needed cushioning under the foot to make walking more comfortable and can be enhanced with other materials for odor control, moisture management, or breathability.

Insoles can be permanently attached to the boots or removable and are available in different materials, including cork, leather, and memory foam.

Midsole

The midsole is located in between the insole and outsole. It provides additional cushioning and shock absorption for a high level of comfort while walking or standing for long periods.

In safety work boots, midsoles can include puncture-resistant enhancements to prevent sharp objects from penetrating to protect the foot from serious piercing injuries.

Shank

The shank is a thin material fitted into the boot between the insole and outsole. It provides the required rigidity to support the boot’s structure under the arch, making steps more stable over different ground conditions. A boot’s shank can be made from metal (such as steel), but other nonmetallic materials – such as nylon, carbon fiber, and Kevlar – can also be used.

It’s worth noting that a metallic shank can add considerable weight to the boots compared to a nonmetallic one.

Outsole

The outsole is the section of the boot directly in contact with the ground or floor you walk on. It sits under the foot and forms a barrier for protection against hard, rough, or unstable surfaces. Outsoles are built using materials such as rubber, cork, and TPU. Depending on their materials and design, they provide a strong grip to prevent slipping and stop water from seeping in from the bottom of the boots.

Ladder Cradle/Grip

The ladder grip or ladder cradle refers to the grooves on the outsole, just beyond the heel and beneath the arch. These notches are designed to hold the boots on more securely to ladder rungs. In addition, they help in preventing the boots from easily skidding off the slippery metal rungs for safer movements while going up and down ladders.

Goodyear Welt

The Goodyear welt is a strip of material that sits between the sole and upper and runs throughout the boot’s perimeter. This strip is sewn into the outsole, while the lining and upper are sewn together to be attached to the boot’s interior. The welt can be made with rubber, plastic, or leather, ensuring a secure connection between the sole and upper and helping seal out excess moisture.

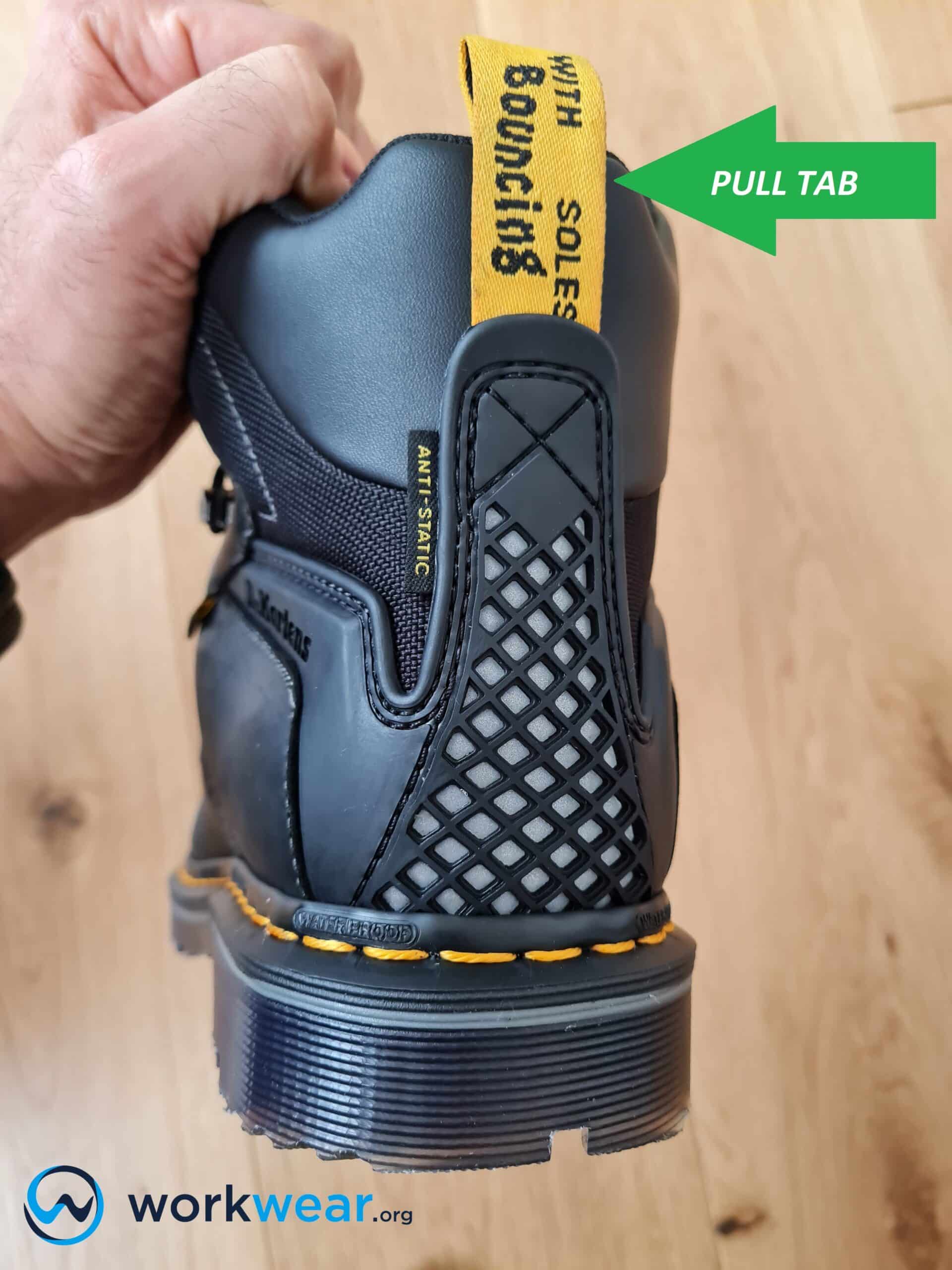

Pull Tab

The pull tab is a loop attached to the collar’s back. It helps with taking the boot on and off in a much easier way without pulling on the collar of the footwear itself.

Stitching

High-quality stitching ensures a secure bond between the leather components and the other parts of the boots. While the method delivers functional benefits in structural reinforcement, it can also be used to improve the aesthetics of boots. For example, detailed stitching or embroidery gives Western or cowboy boots a distinctively eye-catching design, making them stand out from all the other boot styles without compromising performance.

Blake Stitch

The Blake Stitch is the simplest sewing construction method for boots and shoes. This method involves the stitch going through the outsole, insole, and upper, resulting in the structure becoming strongly bonded while retaining much-needed flexibility. Without a welt, the boots look more streamlined and classier with this sewing construction. However, this stitch construction doesn’t offer strong resistance to liquids, which can get into the boots via the holes the stitches went through.

Blucher

Foot Parts

These parts of the foot are protected and supported by various work boot components.

Calf

The calf refers to the portion above the ankle area. In boots, this part’s width can vary from one boot style to another and can significantly impact the level of support and comfort that the wearer can enjoy. The calf is covered and protected by the shaft, which can come in various heights depending on the boot’s construction.

Shin

The shin is found on the front part of the leg below the knee. It’s covered mostly by the boot’s shaft but is also protected by the tongue, which provides welcome cushioning while preventing moisture and debris from getting in. Depending on the boot’s height, the shin can also be covered by the lacing system and often lies just below the lace hooks.

Arch

The foot has three arches – the medial arch, lateral arch, and anterior transverse arch.

The medial arch can be seen on the foot’s inner side and is referred to when discussing if a foot has a high, normal, or flat arch. Meanwhile, the lateral arch is located on the outer part of the sole – the one that’s pressed flat on the ground when standing. These arches are both supported by the sole – with the midsole offering shock absorption and the insole providing the required cushioning and curvature to protect the arches from pain.

Ball of the Foot

The ball area of the foot is located on the sole where the toes meet the foot’s structure. Although it’s naturally well padded, the ball area of the foot can become painful when excessive weight and pressure are placed on it. Ample cushioning from the boot’s insole and specific enhancements can relieve pain on the ball of the foot. In addition, shock absorption from the outsole and midsole can protect this foot part and keep it comfortable with extended periods of walking or standing.

Heel

The heel is located at the back portion of the foot, with enough natural padding around the heel bone to maintain its shape even as it supports the body weight while in motion or stationary.

Without proper arch support and shock absorption, the heel can become painful as it carries the burden of continuous movement and the body’s weight.

Boots with ample cushioning, arch support, and shock-absorbing qualities help prevent heel pain, while the heel counter or backstay keeps it in a stable position.

Conclusion

It can easily get lost among the jargon used for the parts of work boots, so it would be helpful to know what these terms refer to. Knowing the components according to their role in the boot’s structure – and where they’re located – can make it much easier to become more familiar with the terminologies. For example, the boot parts form the structural makeup of the footwear and include the shaft, toe box, safety toe cap, metatarsal guard, foxing, and box stay (heel counter). On the other hand, the leather parts consist of the components that are typically built with leather or are attached directly to the material, such as the upper, shaft quarter, collar, laces, lace hooks, eyelets, eyestay, tongue, vamp, vamp lining, insole, midsole, shank, outsole, ladder grip, Goodyear Welt, and pull tab. Finally, it’s also beneficial to learn which parts of the foot – such as the calf, shin, arch, ball of the foot, and heel – are protected and supported by the various boot components. The information can help you appreciate what each component delivers and make it easier to choose the work boot that best fits your needs.

FAQs

- What role does an inner lining have in work boots?

- The lining adds a soft dimension to the interior of work boots, so they feel more comfortable on the skin. Most inner lining fabrics also promote better air circulation, stop heat build-up, and help prevent odor development.

- Is it always best for work boots to have a gusseted tongue?

- A gusseted tongue protects the feet from harm by preventing debris and wetness from getting into the boot, but there are times when it can cause problems. With the way it’s attached to the boot’s upper, the gusseted tongue can’t be moved out of the way to accommodate the foot’s entry. This can lead to discomfort and a longer time to wear the boot, especially for those with wide feet.

- Does a heel counter always need to be stiff?

- Yes, the heel counter or backstay needs to be stiff to be able to keep the heel secured in place. The rigidity helps improve stability by preventing the foot from sliding within the boot while walking.

- Are safety toes always necessary in work boots?

- Not always. Safety toe caps are required for a safer experience when working in hazardous areas -where there are risks of heavy objects rolling or falling from high places. However, for jobs that aren’t exposed to impact and compression threats, safety toes won’t be needed and may even be a drawback as they can make the boots heavy.