Internal vs External Met Guards – Differences & Similarities

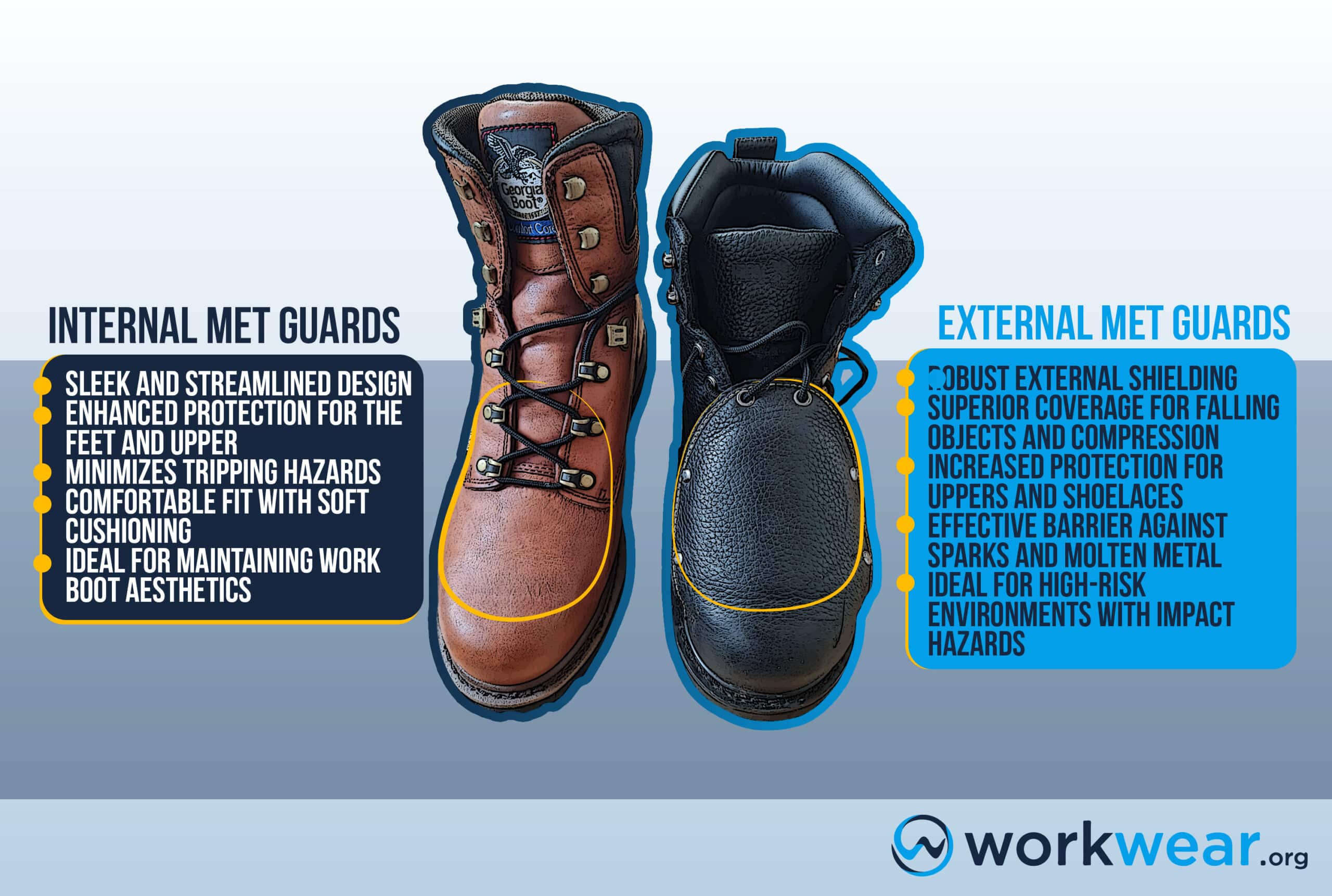

Foot protection from work boots against falling objects isn’t limited to safety toe caps. Metatarsal guards (or “met guards”) offer extended protection, going beyond the area covered by safety toe caps to shield the top of the feet against injuries. These safety enhancements can be outside the work boots or fitted inside. Are you looking for work boots with met guards but don’t know which type is better? You’re in the right place. I’m here to discuss the merits of internal and external met guards to give you a better understanding of how they’ll suit specific jobs and work environments.

Main Similarities

Protection Against Falling Objects

Metatarsal guards are designed to boost the protection offered by safety toes. External and internal metatarsal guards cover a larger portion on top of the foot, protecting the small bones that heavy falling objects can crush. They work with safety toe caps to ensure better foot protection against severe injuries in areas with impact hazards.

Winner: Both met guards offer strong protection against falling objects. However, external met guards win by a slight margin because they typically cover a larger surface area compared to internal met guards.

Protection Against Compression

Met guards block not only falling objects but compression threats as well. Whether built into the work boots internally or externally, they form a barrier against large or heavy objects that can cause dangerous compression over the feet. Met guards prevent crushed bones in case of exposure to hazardous compressions – such as tractor wheels moving over the feet. With safety toe caps, internal or external met guards enhance work boots for continuous foot protection in challenging environments.

Winner: Internal and external met guards protect the feet against compression. However, external met guards have a slight edge because they typically offer more coverage and can hold up better against continuous compression.

Protection Against Sparks or Molten Metal

Met guards shield the feet from additional safety threats. In work areas where sparks and molten metal can splash accidentally, metatarsal guards, internal or external, form a protective barrier over the feet to help avoid serious burns from extremely hot substances.

Winner: Internal and external met cover the top of the feet for enhanced safety against sparks and splashes of molten metal. It’s worth noting that external met guards typically have a larger coverage, so that they may offer slightly better protection in this case.

Foot Comfort and Fit

Metatarsal guards offer superior protection, but this may come at a price. These components are focused on protection and can sometimes sacrifice comfort. Depending on the materials used, external met guards can add significant weight to work boots, making them bulky and uncomfortable for hours of walking. Meanwhile, the placement of internal met guards can make the boots’ interiors too tight, causing pinching and painful friction.

Winner: Met guards are not known for (and not focused on) making work boots comfortable, so both types can’t be considered winners in this aspect.

Main Differences

Protection for the Boot's Uppers

The placement of met guards affects how they can protect the uppers. External met guards create a protective shield outside the boots, typically covering a larger area than internal met guards. Since they’re outside, they protect the uppers and the feet against safety hazards.

On the other hand, internal met guards are fitted inside the boots under the tongue and laces. This position enables the met guards to cover the top of the feet and keep them safe from impact, compression, and hazardous heat. However, their internal placement means they can’t protect the outer parts of the boots from safety risks.

Winner: External met guards win when protecting the uppers because they’re built over the work boots’ structures.

Protection for the Boot's Laces

Metatarsal guards cover the top part of work boots and keep the feet safe from being crushed or burned by hot substances. External met guards also cover most of the lacing system, protecting them from damage that sparks or splashes of metal and other hot elements in the work environment can cause. By shielding the shoelaces, external met guards increase protection for the feet and uppers. On the other hand, internal met guards don’t offer any protection for the laces because they’re placed inside work boots.

Winner: External met guards stand out with superior protection for the shoelaces, blocking splashes of molten metal and sparks that can burn and damage the laces.

Appearance

Met guards affect the appearance of work boots differently, depending on their location. Internal met guards don’t greatly affect work boot aesthetics because they’re hidden inside the boot, under the lacing system and the tongue. Their only effect may be making the boots look a bit thicker.

Meanwhile, the placement of external met guards significantly affects the look of work boots. A met guard covering the top of the boots can give off a strange vibe that not everyone may appreciate. It can also reduce the sleekness of the boots’ profile and negatively affect their overall style.

Winner: Internal met guards win in this aspect because they have minimal to zero effect on the work boots’ appearance, unlike external metatarsal guards that can make boots look strange and too bulky.

Mobility

Met guards and their locations in work boots affect foot mobility differently. Internal met guards can make the boot interiors feel too tight, making it challenging for the foot to flex naturally. They can also cause friction and make certain movements uncomfortable. It’s worth noting that more internal met guards are now designed to be more comfortable, often with better cushioning and flexibility.

Meanwhile, external met guards can feel heavy on the feet, causing discomfort over long periods of walking. If they catch machinery and other objects in the environment, they can make walking more challenging and cause tripping.

Winner: Regarding mobility, there are no winners in this comparison. External and internal met guards have relatively negative effects on how the feet move.

Comparison table

| External Met Guards | Internal Met Guards | |

| Protection Against Falling Objects | Excellent | Very good |

| Protection Against Compression | Excellent | Very good |

| Protection Against Sparks or Molten Metal | Excellent | Very good |

| Foot Comfort and Fit | Weak | Weak |

| Protection for the Boot’s Uppers | Very good | Weak |

| Protection for the Shoelaces | Very good | Weak |

| Appearance | Weak | Very good |

| Mobility | Relatively weak | Relatively weak |

Who's the Overall Winner

External met guards win by a wide margin in this comparison of metatarsal guards. Their external location provides a larger coverage area and protection against falling objects, compression, sparks, and hot substances. They also offer better protection for the uppers and shoelaces, unlike internal met guards that can’t protect these sections because of their location inside the work boots. However, internal met guards win when maintaining work boots’ streamlined looks and don’t become tripping hazards.

Recap

Go for work boots with external met guards if you:

- Work in areas where sparks can fly and hot substances can splash on the boots by accident

- Need outstanding protection against continuous compression and impact hazards

- Want a higher level of coverage for your work boots’ uppers and laces

Choose work boots with internal met guards for:

- Preventing tripping in areas where the laces can catch on surrounding objects

- Maintaining the sleek look of work boots

- Enjoying enhanced foot protection without the extremely bulky look

Personal Testing Experience

Read on for my observations while trying out two heavy-duty work boots with metatarsal guards. The Iron Age Groundbreaker Work Boot was built with a steel toe cap that protected the toes from harm. It also had an external met guard that blocked dangerous compression, impact, and extremely hot substances. Kevlar stitching ensured the boot’s components remained sturdy in the most demanding environments. A memory foam footbed and a heel with a spongy feel helped increase overall comfort. However, the boot still felt quite heavy and didn’t have a waterproof design.

On the other hand, the Georgia Boot Hammer 8-inch Work Boot had steel toe protection and an internal met guard for enhanced foot safety in hazardous work conditions. The exclusive Comfort Core technology made this boot exceptionally comfortable, with the interior having a nicely cushioned and properly ventilated design. The high-traction outsole firmly gripped the ground and prevented slipping on tricky surfaces. Like the first boot, though, this wasn’t waterproof and had a heavy feel.

Conclusion

Metatarsal guards significantly increase the level of protection that work boots can provide. No matter where they’re located, met guards work with steel toe caps to keep the feet safe against crushing injuries and burns. External met guards that cover a larger portion of work boots are slightly better at protecting against continuous compression, falling objects, and hot substances. Their position outside work boots also enables them to shield the shoelaces and uppers against damage. Meanwhile, internal met guards don’t hurt appearance because of their position inside the boots and don’t turn into tripping risks.

FAQ's

- Are met guards also fitted into soft-toe work boots?

- No, met guards are generally built into work boots with safety toe caps.

- Do internal met guards bite into the feet?

- No, they’re often designed with a softly cushioned part that goes over the feet, preventing discomfort even with hours of use.

- What are internal and external met guards made of?

- Metatarsal guards can be made from different materials, including steel, aluminum, and composite components.

- What work boots styles usually have internal or external met guards?

- External or internal met guards are typically built into heavy-duty work boots, such as those used by workers in mining, construction, logging, and manufacturing.

678+

Products Reviewed

24+ Years

Combined Experience

500+ Hrs

Field Testing