What are Work Jackets Made Of?

Work jackets are important parts of your work attire – whether outdoors, working in inclement weather, or finishing your tasks indoors. They shield your body from the elements and can act as the first line of defense against abrasion and other safety hazards in the work area. In addition, work jackets are built specifically constructed to keep you moving comfortably while enjoying the enhanced designs offering superior performance while on the job. But do you know what materials are used for work jackets? In this article, we’ll discuss the materials that go into the different sections of a work jacket to give you a better idea of how each one affects the appearance and functionality of the outerwear.

Getting to know the various materials can also make it easier for you to choose the best work jacket that suits the requirements of your job.

Key Takeaways

- Work jackets are made up of different sections that use various materials. These materials have unique characteristics that significantly impact the jackets’ appearance and function.

- The work jacket’s exterior or shell is the section that has the highest exposure to the elements and dictates the garment’s aesthetic. Cotton duck, cotton canvas, and denim are sturdy, durable materials that are ideal for challenging worksites. These materials are also showcased in work jackets with versatile styles.

- Polyester and nylon are lightweight yet durable materials for work jackets’ outer shells. Fleece, wool, and flannel all have comfortably soft qualities that retain warmth and work well in cold settings. Meanwhile, polyurethane has strong liquid resistance featured in waterproof or water-repellent work jackets.

- The work jacket’s lining sits between the outer shell and the skin and is mostly made of soft fabric. Nylon is a durable and smooth material that can come in quilted or mesh structures, while quilted fabrics with extra padding and insulation. Flannel and fleece both deliver comfortably soft textures, while Shearling or Sherpa linings create a soft and fluffy interior that’s enjoyable to use.

- The filling or insulation material provides and retains heat, making the work jacket comfortable for cold-weather use. Down insulation is light and long-lasting, while synthetic insulation is more affordable and more suitable for wet conditions. On the other hand, fleece and wool are breathable and comfortably soft materials that preserve cozy warmth.

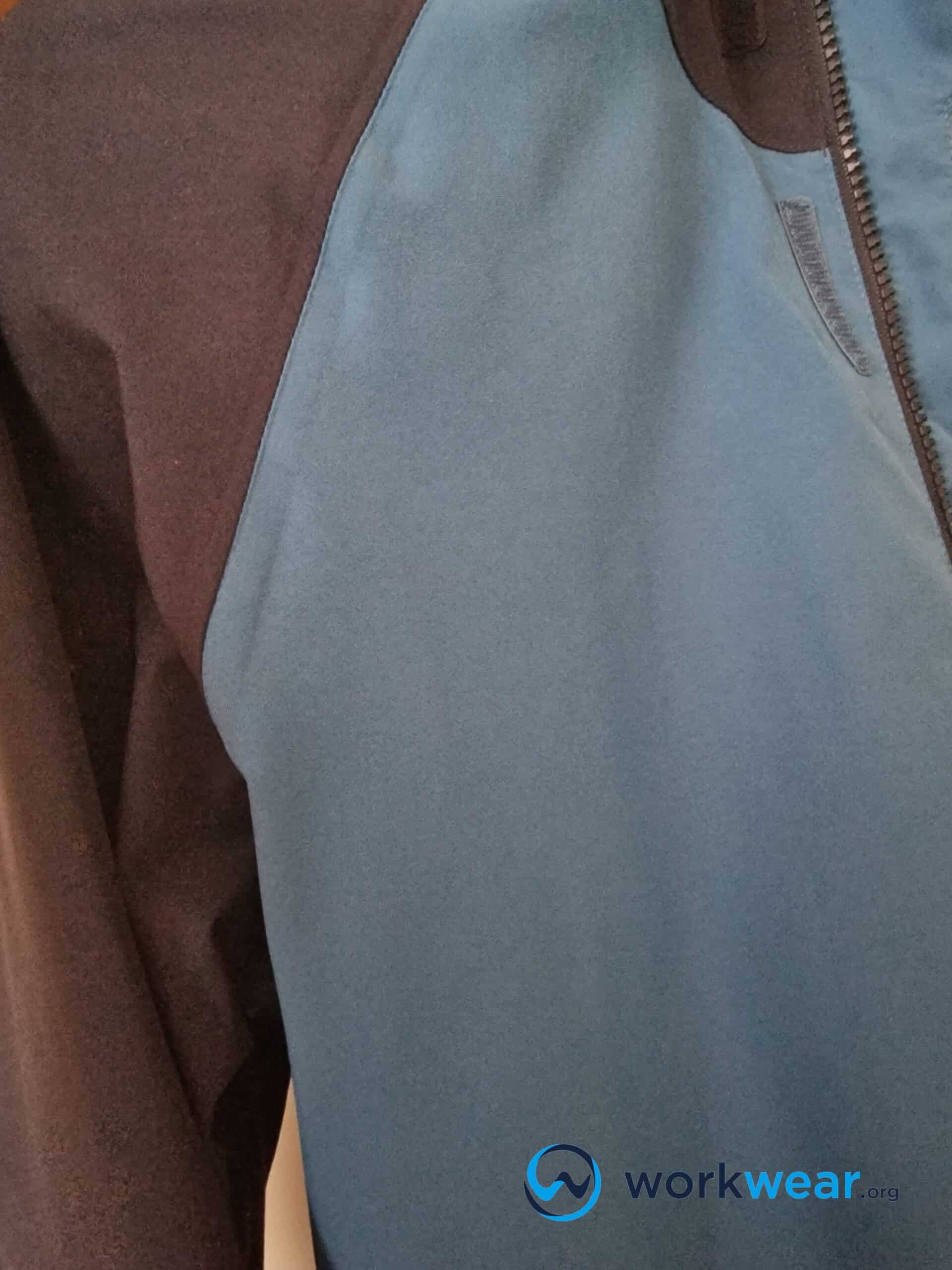

Shell

This refers to the exterior part of the work jacket most exposed to the elements. It forms a barrier for the jacket’s materials and your body, protecting it against abrasions and other safety hazards.

The shell can be made from different fabrics and dictates the style and color of the work jacket.

Cotton Duck

Cotton duck is a tightly woven fabric that’s durable and can resist tearing and snagging – which is why it’s one of the most common and preferred materials for making work jackets and industrial workwear.

This breathable material allows a good amount of air to pass through, preventing overheating that may build up after long hours of jacket use while dealing with strenuous tasks. As a result, the hardwearing fabric is suitable for many work environments. Still, it is especially useful for jobs in challenging settings, which need work jackets that are tough enough to withstand continuous use and abuse. The cotton duck may shrink over time and fade when used frequently under the sun.

Cotton Canvas

Cotton canvas is a material that was first used for making tents and boat sails.

This fabric features a very firm and compact weave, resulting in exceptional strength that’s ideal for work jackets that are meant to be used in challenging surroundings.

The waterproof and windproof material creates jackets that keep you comfortably dry and protected in windy and rainy conditions.

However, the fabric is expensive, isn’t very breathable, and can feel a bit abrasive.

Denim

Denim work jackets are usually made with 100% cotton, but the material is thicker than plain cotton. The thickness adds more strength to the denim material, making it more resistant to wear and tear as it keeps you protected against the wind.

Denim jackets are breathable and won’t cause sweat and heat to build when they’re used in warm weather conditions.

They’re versatile additions to working attire, offering warmth without the heavy feel. Jean jackets also inject a rugged vibe to outfits that can be maximized in and out of the work area.

However, they’re not water resistant, so they don’t offer protection against liquid penetration. The denim material also tends to fade and stretch over time, although the fading may add a lovely, aged quality to the work jacket in the long run.

Polyester

Polyester can be used on its own or blended with other materials (such as cotton) for the exterior shells of work jackets.

It has a flexible, lightweight quality suitable for mild weather and slightly windy conditions, easily conforming to the body for a comfortable experience.

The versatile material can also be used in the inner lining and filling of work jackets. In addition, polyester is naturally water resistant and quick drying, so jackets made with this material can keep you dry in case you’re exposed to light rain while working outdoors. However, work jackets with pure polyester shells won’t protect against strong winds, so thicker or stronger materials are needed.

They’re also not as breathable as cotton duck or denim jackets.

Nylon

Nylon is a synthetic material that’s lightweight enough not to weigh you down even during the busiest days. In addition, it provides strong resistance to water and wind, so nylon work jackets are suitable for working outdoors during windy days when there’s a chance of rain.

The material is durable, with some types – such as Ripstop nylon – offering enhanced durability against rips and abrasion.

It isn’t prone to shrinking and has a versatile structure that can be enjoyed in many jacket designs.

Nylon work jackets aren’t very breathable or easy to clean, though, and they tend to make a swishing sound when rubbing against the same material – which may happen when you swing your arms.

Fleece

Fleece can be made from different raw materials, such as cotton, wool, and polyester. The material has a fuzzy texture that makes work jackets very comfortable.

Work jackets made with fleece shells can offer superior warmth to take on cold job areas, with some having anti-pilling qualities for superior durability in different work settings.

Fleece is water-repellent, so it can keep you comfortably dry when you need to work in wet conditions.

It can also be used in the lining of work jackets, but it can retain odors and may be more difficult to clean than low-maintenance fabrics.

Polyurethane

Polyurethane is usually seen in work jackets or coats with waterproof or water-resistant exterior shells.

This plastic fiber material is inexpensive and offers superior protection against rain and other sources of extreme moisture. As the plastic material isn’t the most comfortable against the skin, work jackets with PU often come with a softer and much more welcoming inner lining.

It’s worth mentioning that PU isn’t breathable, so sweatiness and heat can build up after long hours of jacket use. Work jackets made with polyurethane shells also don’t retain comfortable warmth, making them unsuitable for cold conditions.

Wool

Wool comes from animal sources, such as sheep and goats. The wool yarn from an animal’s coat is woven into the fabric used to make clothing, including work jackets.

Wool offers natural insulation that can offer serious warmth, making wool jackets ideal for cold work areas.

The material is resistant to wrinkling, so it won’t look crumpled while you’re dealing with a variety of tasks in the workplace. It’s also naturally moisture-wicking to prevent sweat buildup.

However, it can feel scratchy on the skin and requires dry cleaning.

Flannel

Flannel is a soft woven fabric typically made from cotton and enhanced to deliver a higher level of warmth.

The material is often brushed to create a distinctively soft texture, making flannel work jackets ideal for those who prefer their workwear to be extra-comforting.

Flannel traps heat to ward off the uncomfortable chill, so jackets made with this material are great for cold environments, especially if they have a built-in insulating layer. In addition, the fabric is breathable, so there’s less chance of overheating and excessive sweating if the jackets are used in suddenly warm surroundings.

It’s worth noting that the fabric is prone to shrinking and pilling, which can negatively affect the work jacket’s appearance and function.

Shell/Exterior Material

| Type |

Pros |

Cons |

|---|---|---|

| Cotton Duck |

|

|

| Cotton Canvas |

|

|

| Denim |

|

|

| Polyester |

|

|

| Nylon |

|

|

| Fleece |

|

|

| Polyurethane |

|

|

| Wool |

|

|

| Flannel |

|

|

Lining

The lining is the material between your skin and the outer shell.

It’s made with materials that deliver enhanced softness for a more comfortable jacket-wearing experience, as it protects the skin from rubbing against the exterior fabric. It can also add a warm layer to the interior for better comfort in cold settings. The lining also maintains the work jacket’s structure, so it doesn’t look shapeless.

Nylon

Nylon is used in work jackets’ exterior shells and as an inner lining material.

The durable material helps preserve the jacket’s shape from within and doesn’t easily get damaged even with extensive use, so you won’t need to worry about easily wearing out the jacket.

The material can be used in a quilted form that’s a bit bulkier and offers enhanced warmth inside, but nylon mesh promotes better air circulation inside the jacket.

Nylon isn’t very easy to clean, though, so using this material in the jacket’s lining may require extra effort for cleaning.

Flannel

Just like nylon, flannel is used in the exterior and the lining of work jackets. The soft texture makes it a superbly comfortable material against the skin.

Flannel adds much-needed warmth to jackets used in cold settings and helps retain a cozy feeling without the uncomfortable bulk.

Its breathable quality allows sweat and heat to escape quickly, so there’s a minimized risk of overheating even when the jacket is used in warm environments.

The material can easily get snagged and is prone to pilling, so extra care should be exercised when using a flannel lining jacket.

Quilted fabric

Quilted fabric is used as a lining in work jackets that are designed for use in cold conditions.

This is because insulating material (such as cotton or wool) is placed in between the two pieces of fabric that are sewn together to form the quilted patterns. The quilted fabric can be made from cotton, nylon, or other soft fabrics.

With the insulating material inside the quilted structure, the lining increases the jacket’s warmth and gives it a bit of bulk that helps with heat retention and comfort. The fabric also lends a softly padded structure to the jacket’s interior.

However, quilted fabrics can also retain moisture, making it more difficult for sweat to dissipate.

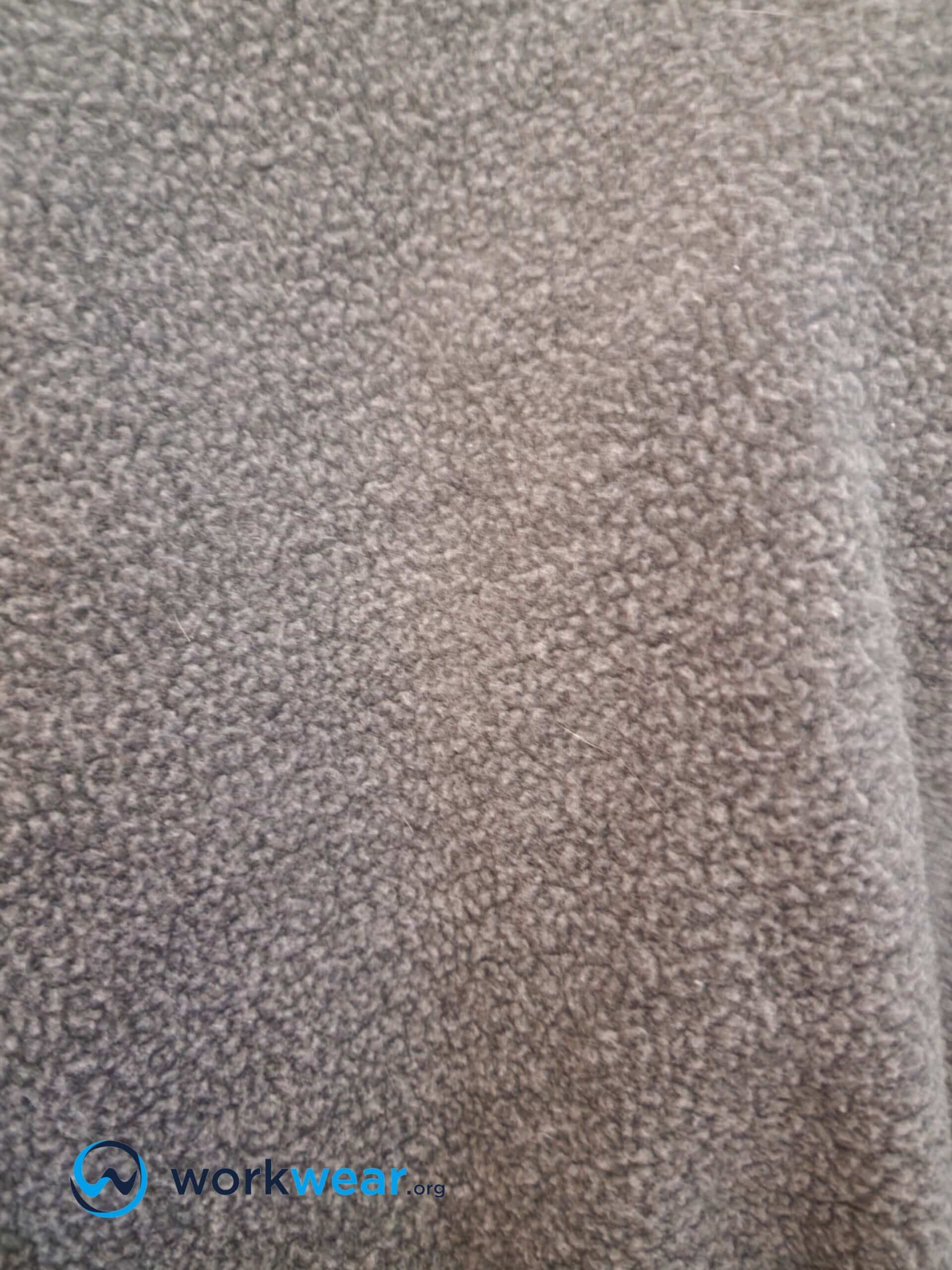

Fleece

Fleece lining adds a fuzzy softness to the interior of work jackets, making them comfortable to wear even while doing the most difficult tasks.

The material retains enough heat to preserve a cozy feeling inside the jacket when worn in cold conditions.

Fleece is naturally hypoallergenic and is ideal for those with sensitive skin that may be irritated by other materials. In addition, the breathable material allows the air to circulate to prevent overheating and excessive sweating when the day suddenly turns a bit warmer.

Fleece is a bit challenging to clean and can retain unwanted smells. It’s also prone to pilling and needs extra care to prevent premature damage.

Sherpa/Shearling

Shearling is a type of wool that’s sourced from a lamb that only had a single shearing, while Sherpa (also referred to as “faux shearling) can be made from a blended fabric containing cotton, acrylic, or polyester.

These materials make the interior of work jackets comfortably soft, with just enough thickness to retain ample warmth for comfort without being excessively bulky. In addition, they both have moisture-wicking properties to prevent sweat buildup, which can be a risk when working in areas that can unexpectedly become warm.

Shearling and Sherpa can both get dirty easily, though, so they’re not recommended for those who prefer work jackets with low-maintenance materials.

Lining Materials

| Type |

Pros |

Cons |

|---|---|---|

| Nylon |

|

|

| Flannel |

|

|

| Quilted Fabric |

|

|

| Fleece |

|

|

| Shearling/Sherpa |

|

|

Filling/Insulation

The filling makes work jackets warm enough to be used in cold environments.

It can also be referred to as insulation as it helps trap ample heat to keep the body comfortably warm while working in low-temperature job locations.

Work jackets without great insulation are suitable for warm surroundings since they generally have cooler, more lightweight structures.

Down

Down insulation for work jackets is sourced mostly from ducks or geese, creating a work jacket filling that’s much easier to compress than synthetic materials.

This material is lighter than synthetic insulation and lasts longer, providing much-needed warmth in cold settings for a long time, even with heavy use.

The warmth is trapped between the down filaments, with a higher loft or puffiness creating a warmer feel.

However, the insulation property of down significantly decreases when it gets wet, making it unsuitable for cold surroundings that risk getting wet. It’s also more expensive than synthetic insulation.

Synthetic Insulation

Synthetic insulation uses polyester fibers to retain heat and keep the jacket warm enough to be used on cold job sites.

Synthetic insulation made of higher-quality polyester fibers is softer and can trap more heat. They can also be enhanced to deliver strong resistance to liquids and odors and are generally more affordable than down insulation.

Synthetic insulation is much better for wet settings as it dries faster than down.

It’s worth noting that the synthetic material is bulkier and heavier than down and typically wears down more quickly.

Synthetic insulation can come in many forms, often in products exclusive to specific manufacturers. Examples are PrimaLoft,3 M’s Thinsulate, Columbia’s Omni-Heat, and Invista Corporation’s Thermolite.

Fleece

The fleece lining fitted into some work jackets is also an insulation material.

It can retain heat, although not as efficiently as synthetic or down insulation.

Fleece comes with a comfortably soft texture and is breathable, enabling moisture to dissipate and prevent a sweaty feeling easily. It also dries quickly, making it ideal for work conditions with exposure to wetness.

Fleece doesn’t easily compress, so work jackets made with this lining or insulation material can be bulkier than those with down or synthetic insulation.

Wool

Wool is used as a filling material to trap enough heat, effectively warding off the uncomfortable chill in low-temperature work areas.

Wool is a natural alternative to synthetic insulation, offering soothing softness that significantly enhances comfortable use.

Jackets with lighter wool insulation are ideal for mildly cold surroundings, while the ones with heavier filling are better suited for considerably colder environments.

However, wool typically costs more than the other insulation materials and is harder to clean and maintain.

Filling/Insulation Materials

| Type |

Pros |

Cons |

|---|---|---|

| Down |

|

|

| Synthetic Insulation |

|

|

| Fleece |

|

|

| Wool |

|

|

Conclusion

Work jackets have different parts that are, in turn, made from different materials. Knowing these materials can make it a lot easier for you to choose the work jacket that’s most appropriate for your job and suits your comfort and style preferences. The shell or exterior is the section most exposed to the elements and has the biggest impact on appearance. Cotton duck, cotton canvas, and denim are hardwearing materials ideal for tough worksites, while polyester and nylon have lightweight structures that last long. Wool, flannel, and fleece offer comfortable softness and warmth, while polyurethane stands out with superior water resistance.

Meanwhile, the lining creates a soothing barrier between the shell and the skin, with nylon being a popular choice for its smooth and durable structure. Fleece, flannel, and Sherpa or Shearling are lining materials that elevate comfort with their softness and heat retention properties. Lastly, insulation or filling materials take on the role of preserving comfortable warmth for jackets that are created for cold environments. Down offers long-lasting, lightweight insulation, while synthetic insulation is cheaper and more efficiently insulates in wet conditions. On the other hand, wool and fleece make work jackets more comfortable to use with their soft and fluffy profiles.

FAQs

- When makes synthetic insulation better than down?

- Synthetic insulation is a better alternative in work jackets for people with allergies to duck or geese. It’s also a better choice for working in wet conditions since the polyester fibers don’t clump together, continuing to deliver high-quality insulation.

- Why do some work jackets have nylon lining only on the sleeves?

- The nylon lining, especially in a quilted design, makes the interior of sleeves much smoother, so they’re easier to slip on and off.

- Can cotton duck work jackets be used in wet work areas?

- Yes, cotton duck with a water-repellent finish can resist liquids and protect you against wetness.

- Can you still wear insulated work jackets even if it’s not wintering anymore?

- Yes, but it’s best to stick to insulated jackets with lightweight and breathable profiles to prevent an overwhelmingly warm feeling.

678+

Products Reviewed

24+ Years

Combined Experience

500+ Hrs

Field Testing