What is a Shank in Work Boots

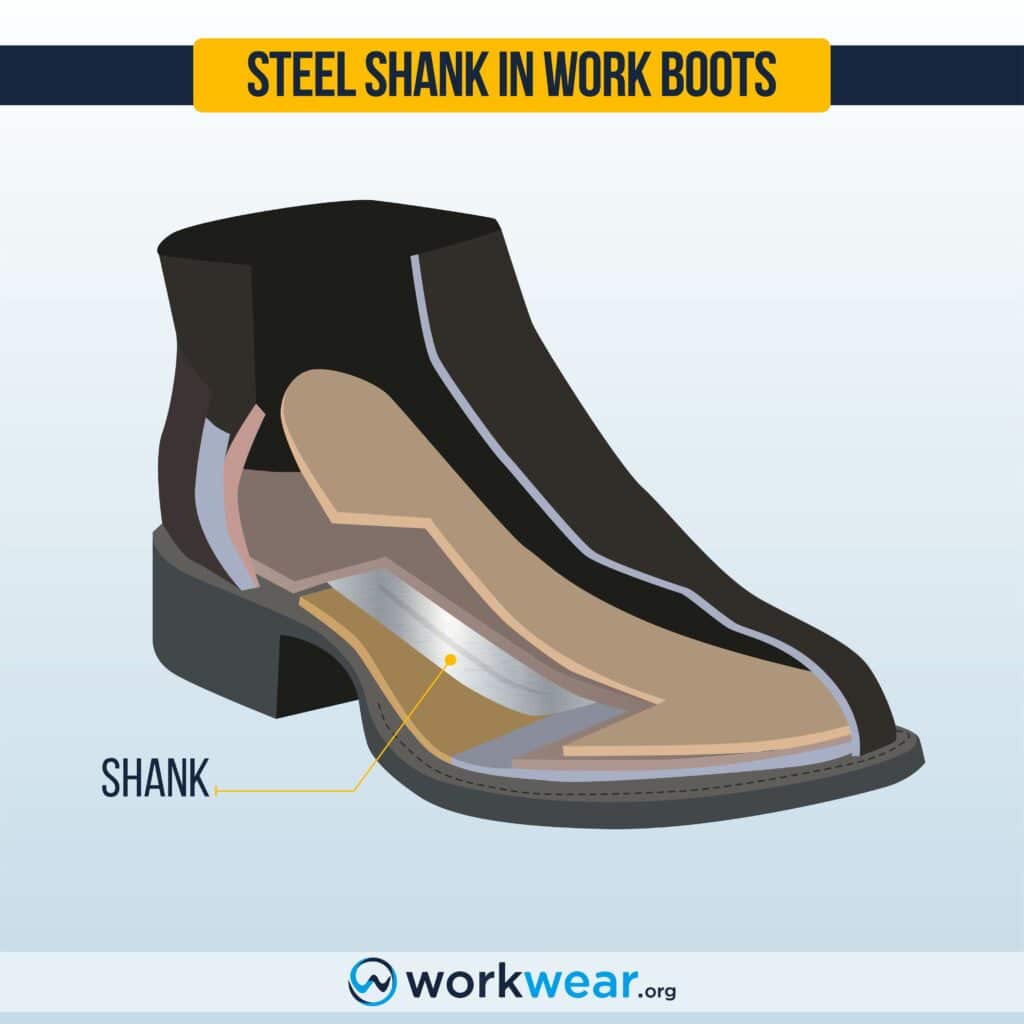

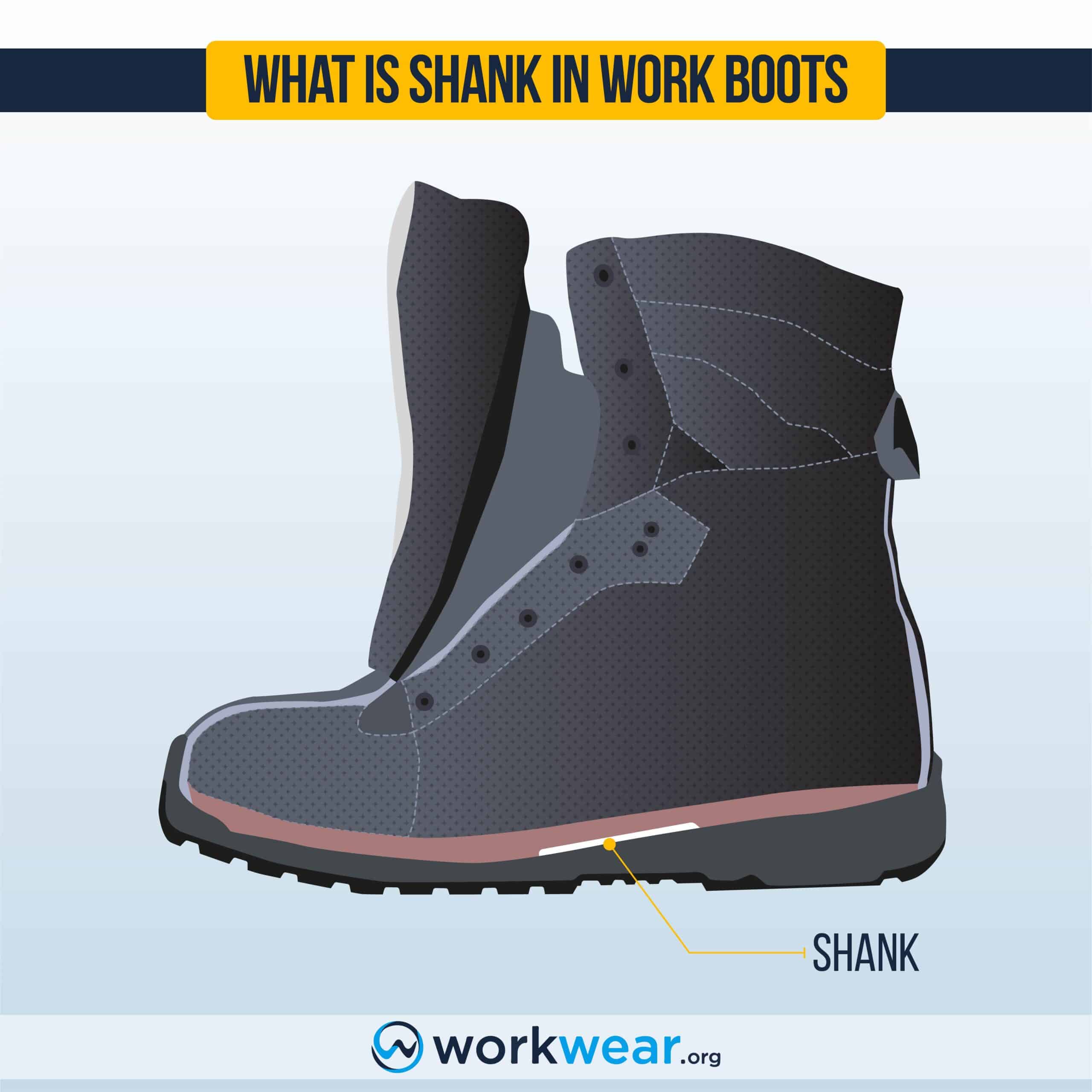

Work boots comprise different parts besides easily visible ones (such as the uppers and soles). However, the hidden parts are just as crucial in ensuring that the boots perform to the highest level, making them suitable for work settings. One such component that’s not visible is the shank, which is built into the boot’s structure – in between the insole and the outsole.

A shank helps improve stability while walking and enhances the boot’s ability to maintain its shape for much longer.

It can be made with steel (like the one in the Caterpillar Second Shift Steel Toe Work Boot) and other materials, including carbon fiber and leather. In this article, we’ll discuss the other information you need about this part that’s rarely mentioned but still plays a key role in a boot’s functionality.

What is a Shank?

A shank is a long, narrow piece of material built into the boot between the outsole and the insole. The main objective of this element is maintaining the boot’s structural strength, delivering the required rigidity at the bottom to create a firm platform.

A shank gives the support needed to stabilize walking, especially over uneven or sloped ground conditions.

It also stops the middle of the sole from sagging over time due to continuous boot use.

Steel is arguably the most popular material for a boot shank due to its reliable strength and stiffness, which are needed to maintain its shape for long-term use.

Non-metallic materials are also used to keep the boot shank more lightweight and airport friendly since steel tends to weigh more and can accidentally trip off metal detectors.

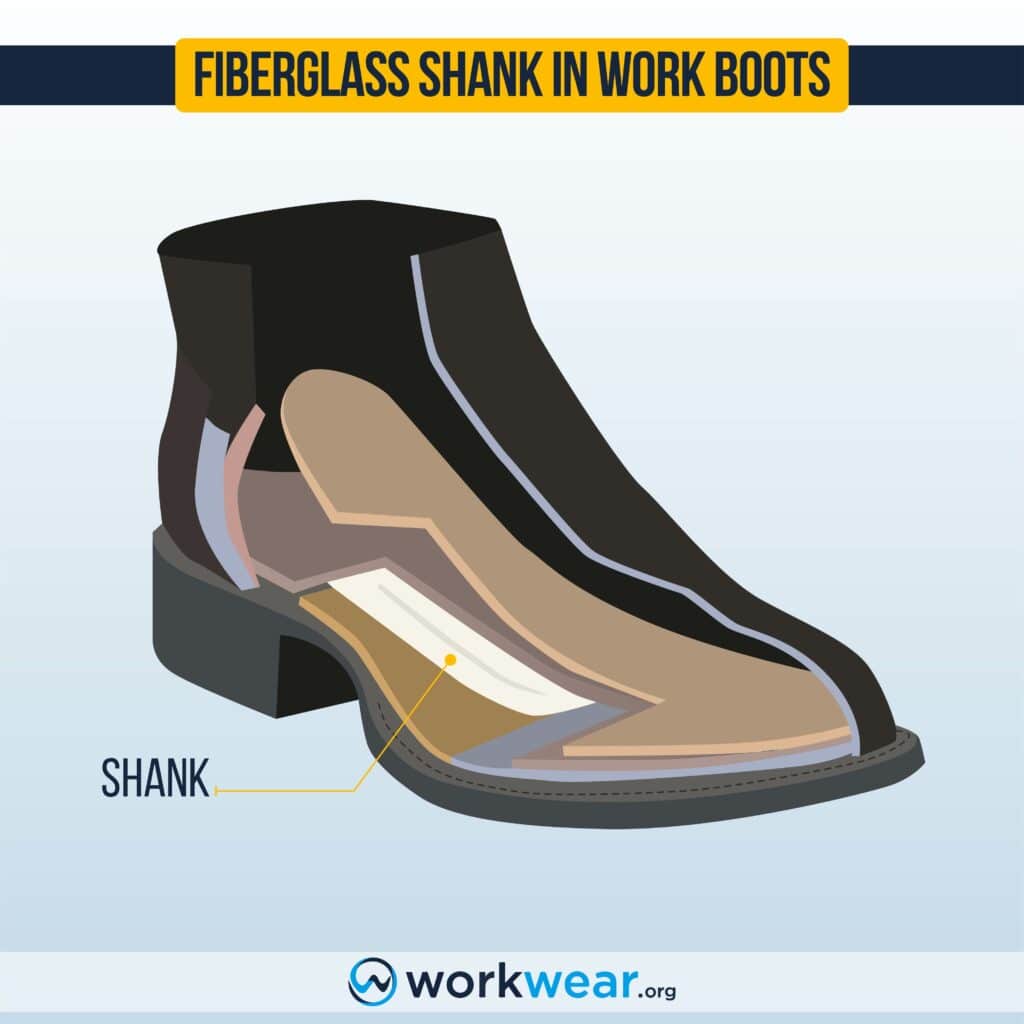

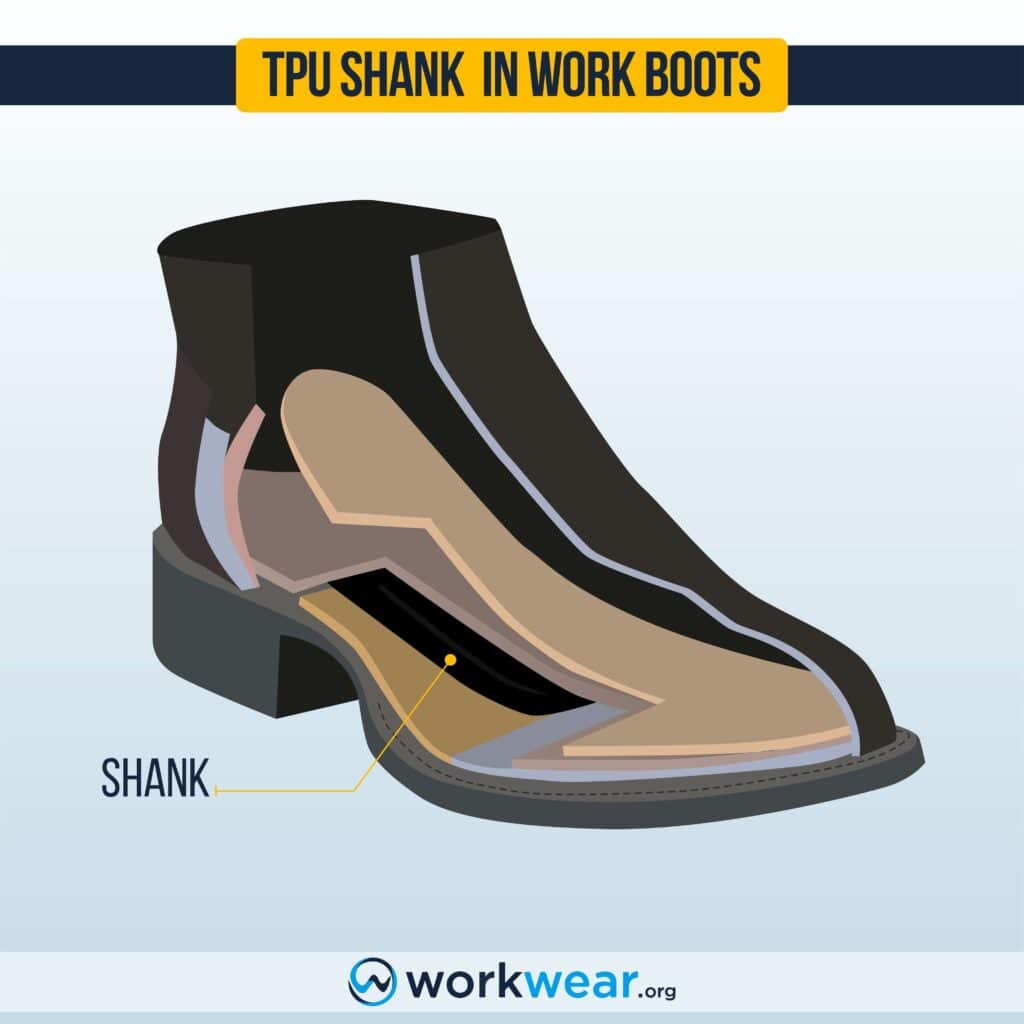

Some metal-free options for boot shanks include fiberglass, plastic, nylon, leather, TPU, and Kevlar.

Wood is sometimes used in boots, although these shanks are more flexible than non-metallic materials.

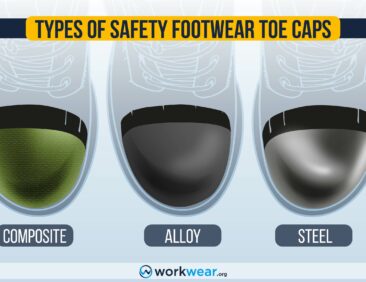

Is a Steel Shank the Same as a Steel Toe?

No, a steel shank isn’t the same as a steel toe.

They’re steel-made but have different roles in a boot’s overall performance.

A steel shank gives the sole stiffness, enabling it to support the foot and keep it stable for easier, more efficient walking over varying surfaces.

It’s embedded into the midsole and helps maintain the boot’s high-quality structure, preventing the sole from sagging in the middle after it’s been used for a long time.

The shank’s rigid structure offers good arch support and promotes proper foot alignment, easing the stress off the foot and leg muscles’ load-bearing roles.

Depending on the material, a shank can fully or partially stop sharp objects from piercing through the sole.

However, the puncture protection is limited to the narrow area where the strip of material is placed on the sole.

On the other hand, a steel toe is built into the toe box at the tip of the boot.

The steel toe cap acts as a barrier over the toes, shielding them against crushing injuries if heavy objects – such as large boxes or tools – are accidentally dropped or rolled on the feet.

The rigidity of steel toes can also help preserve the toe box’s original shape, so it looks and performs as required for much longer.

What is a Composite Shank in Boots?

A composite shank uses a non-metallic material instead of steel.

Some of the most common materials used for a composite shank include carbon fiber, Kevlar, nylon, TPU, plastic, and fiberglass. Composite shanks – such as the Timberland PRO Titan 6-Inch Alloy Toe Waterproof Work Boot’s nylon shank – are more lightweight than steel.

Work boots with these non-metal enhancements are more comfortable since they don’t drag heavily on the feet.

Composite shank boots (including the Under Armour Stellar Tactical Boot with a TPU shank) are also more flexible and can give the feet a wider range of motion than steel shanks.

|

Pros |

Cons |

|

|---|---|---|

| Steel Shank |

|

|

| Composite Shank |

|

|

How to Tell if a Boot Has a Steel Shank?

The most reliable way to know whether a boot has a steel shank is to check the manufacturer’s label or product description.

However, in case there isn’t any indication about the presence of a steel shank, there are several signs that point to this enhancement in place, such as:

- The sole feels more rigid (compared to boots with flexible soles). The stiffness is even more apparent while walking, running, jumping, or climbing (ladders or stairs).

- Strong arch support that helps maintain the foot’s correct alignment.

- The midsole feels considerably stiffer than other materials, which easily flexes along with each step.

Leather Shank Boots

Leather shank boots use leather instead of steel to make the sole stiffer and, as a result, more supportive for the feet.

The leather used in a boot shank is stronger and more rigid than the one commonly used for boot uppers.

It has a structure closer to leather soles that can soften a bit after the boot is used for a while and is properly broken in.

Leather shanks are usually seen in woodland fire boots that keep the feet safe against the extreme temperatures of extremely hot surroundings because they don’t conduct heat.

Leather shank boots also don’t conduct electricity, creating a stable platform significantly reducing the risk of electric shock in environments with electrically energized objects.

Conclusion

A boot shank may easily be ignored or forgotten because it’s not visible, but it’s a critical element that significantly affects a work boot’s performance. Boot shanks improve the boots’ durability by stopping the soles from flexing excessively, so they can maintain their structural integrity for much longer. They support the feet’s natural alignment for better comfort and balance, making it easier to walk stably over varying ground conditions. Steel and composite boot shanks help with weight distribution and absorb some impacts from walking on hard ground, protecting the foot muscles and bones from severe strain.

FAQs

- Does every work boot need a shank?

- Not every work boot needs a shank, but it significantly improves stability, support, and footwear durability. A shank is also crucial for jobs that involve walking on rough or unstable terrains and for professions (such as linemen) requiring going up and down ladders.

- Can a shank help improve a boot’s durability?

- A shank makes the sole more rigid, so it doesn’t flex too much when walking or easily sag in the middle – which is a common problem when boots without shanks are used for a long time.

- Do shanks help ease foot discomfort?

- Yes, shanks can help discomfort by offering a stable base to support the feet to promote their proper alignment. The shanks also absorb some impacts from continuously walking on hard ground, easing the uncomfortable impact on the foot’s bones and muscles.

- Is a steel shank good for cold conditions?

- A composite shank may be better for work boots in cold environments. Steel can conduct cold, allowing it to seep more easily from the boot’s exterior. On the other hand, a composite shank without metal parts will not absorb the low temperature of the environment, preserving the warmth to keep the foot comfortable.

678+

Products Reviewed

24+ Years

Combined Experience

500+ Hrs

Field Testing