Eyelets vs Lace Hooks: Understanding the Differences and Choosing the Right Option for Your Footwear

While getting ready to start your day, you’ll likely be on auto-pilot mode as you lace up your work boots. The main component may be the shoelaces when tying them up, but this can only be done successfully if your boots have eyelets and lace hooks.

These often-ignored parts of a boot play a key role in securing the shoelaces and adjusting them according to the wearer’s needs.

While they constitute a relatively small portion of the footwear’s anatomy, eyelets and lace hooks are just as important as other elements regarding work boots’ aesthetics and function. In this article, we’ll learn more about these parts of footwear to better understand how they function.

Eyelets

Eyelets are the small holes on the top part of the work boot.

These tiny openings are where the shoelaces go through, holding the shoelaces in place to keep the feet secured inside the footwear.

They allow the laces to move smoothly when they need to be loosened or tightened, allowing easy fit adjustments without negatively affecting the work boot’s upper structure. Eyelets are typically designed to blend seamlessly into the boots’ structure, but some (such as those with metallic hardware) stand out against the plain material of the upper.

Types of Eyelets

Punched

As the name suggests, this type involves punching holes in the throat or top portion of the work boot to create the eyelets.

The resulting holes are reinforced with metal or plastic materials placed on both sides of the eyelets.

The reinforcement protects the eyelets against easily getting damaged by the friction and force from tying and untying the laces. In addition, it can have the same color as the upper material (such as black plastic on black leather) for a more unified look. Work boots with heavy-duty designs may also have eyelets with metallic reinforcements that stand out against the upper (like the Keen San Jose Boot), with the eyelets’ shine injecting a bold vibe into the aesthetics of the upper. Punched eyelets are the most common type of eyelets.

However, they can sometimes make the laces more challenging to adjust.

Key Advantages of Punched Eyelets

- Reinforced to prevent tearing

- Can blend in or stand out against the upper’s appearance

Key Disadvantages of Punched Eyelets

- Reinforcement can put pressure on the feet

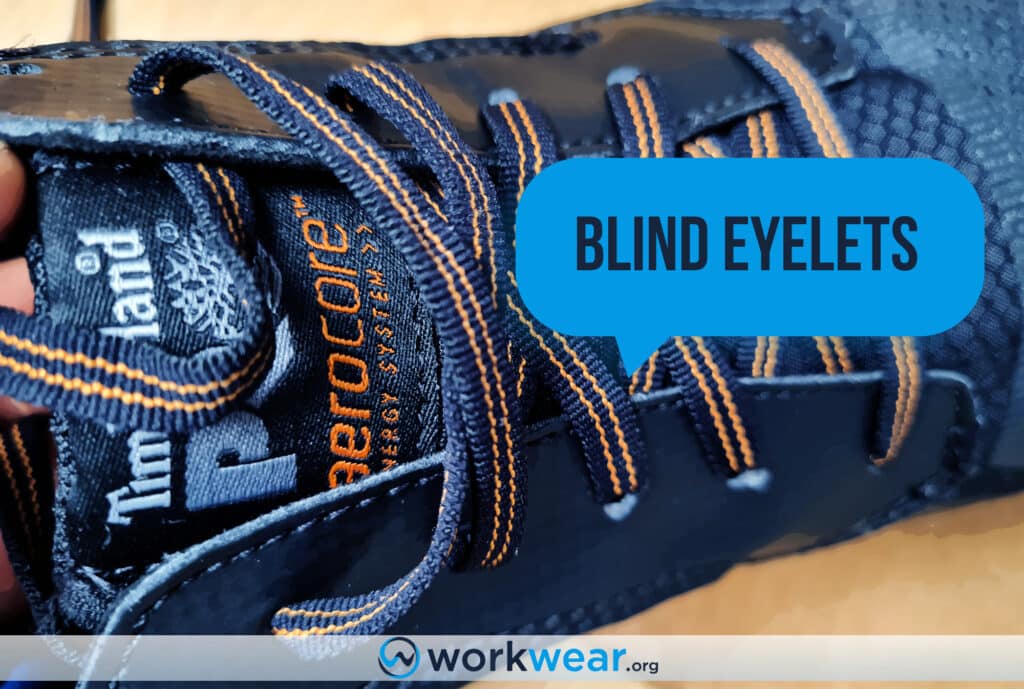

Blind

Blind eyelets are similar to punched eyelets, built by punching holes in the top section of the boot’s upper.

The main difference between the two types is that the plastic or metal reinforcement on blind eyelets is placed only underneath the upper, where the material can’t be seen.

This design leaves the upper with an almost flawless look, as no other materials and textures mar the clean lines. The holes of blind eyelets are usually smaller than punched eyelets, so this type is most often seen in dress shoes (such as the Clarks Tilden Walk Oxford Shoe) and more formal-looking boots. However, blind eyelets are also built into work boots with more robust features, such as the Caterpillar Parker Steel Toe Work Boot.

It’s worth noting that sometimes laces can catch onto the eyelets, making them more difficult to pull through and adjust.

Key Advantages of Blind Eyelets

- Seamless appearance on the upper

- Ideal for dress shoes

Key Disadvantages of Blind Eyelets

- Laces can get caught, and difficult to pull through the holes

- It can more easily tear

Webbing

Webbing eyelets differ the most from the other types of eyelets regarding appearance.

Instead of holes punched on the upper, pieces of leather or fabric are folded to make loops where the shoelaces are designed to go through.

These loops are typically fitted onto sneakers and other footwear with casual styles. Still, they’re also seen in some heavy-duty work boots, such as the Ariat Telluride Composite Toe Boot. The materials are often lightweight and don’t push onto the feet from above, unlike reinforced eyelets that can sometimes cause discomfort when the shoelaces are tightly tied.

However, how webbing eyelets are built makes them more prone to tearing than the punched types.

With frequent pulling, webbing eyelets risk being torn from the top of the upper. This vulnerability is also because the eyelets are attached or sewn, not part of the upper structure like punched eyelets.

Key Advantages of Webbing Eyelets

- Lightweight

- No pressure on top of the foot

Key Disadvantages of Webbing Eyelets

- More prone to damage than punched types

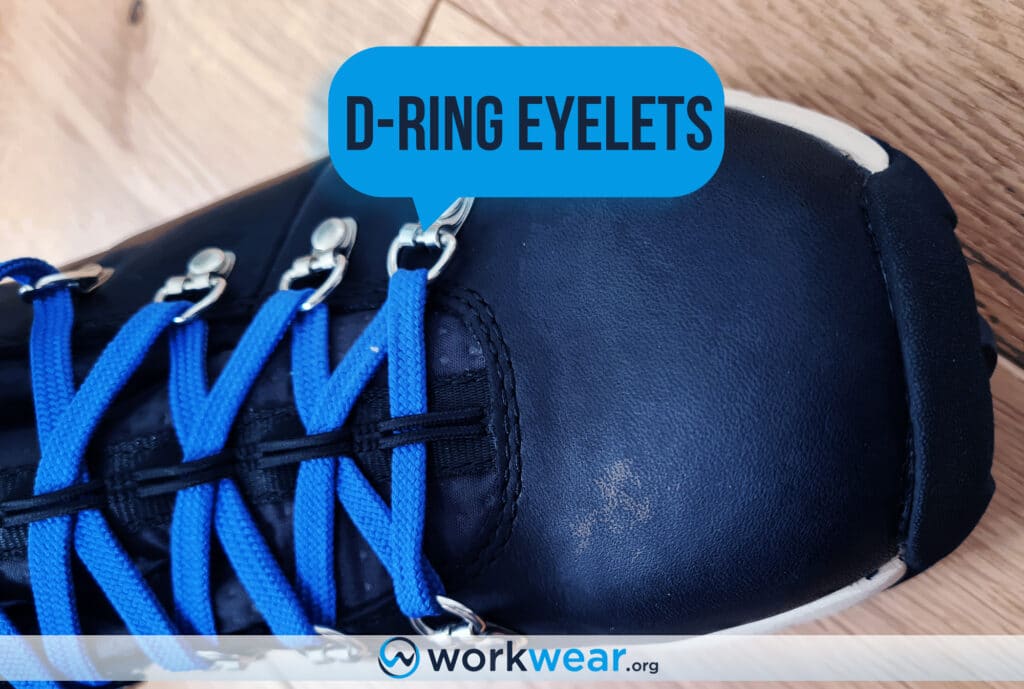

D-Ring

D-ring eyelets have a distinctive look that distinguishes them from the more common punched eyelets.

They’re metal components that look like the letter “D”, with the rounded portion holding the laces secure while the straight area is fitted into the rivets that are attached to the boot’s upper.

D-rings can be used the same way as webbing eyelets, as the loops allow the laces to pass through while securing them easily. D-ring eyelets are made with metal parts, making them stronger and more durable than webbing types. They’re frequently fitted into military boots and hiking boots (or work boots with hiking boot designs, such as the Danner Mountain 600 Boot.)

However, the rivets connecting the rings to the upper can dig painfully into the foot from above.

Key Advantages of D-Ring Eyelets

- Easily allow the laces to go through

- More convenient fit adjustment

- Stronger than webbing

Key Disadvantages of D-Ring Eyelets

- Rivets can dig into the foot

| Types of Eyelets |

Pros |

Cons |

|---|---|---|

| Punched |

|

|

| Blind |

|

|

| Webbing |

|

|

| D-Ring |

|

|

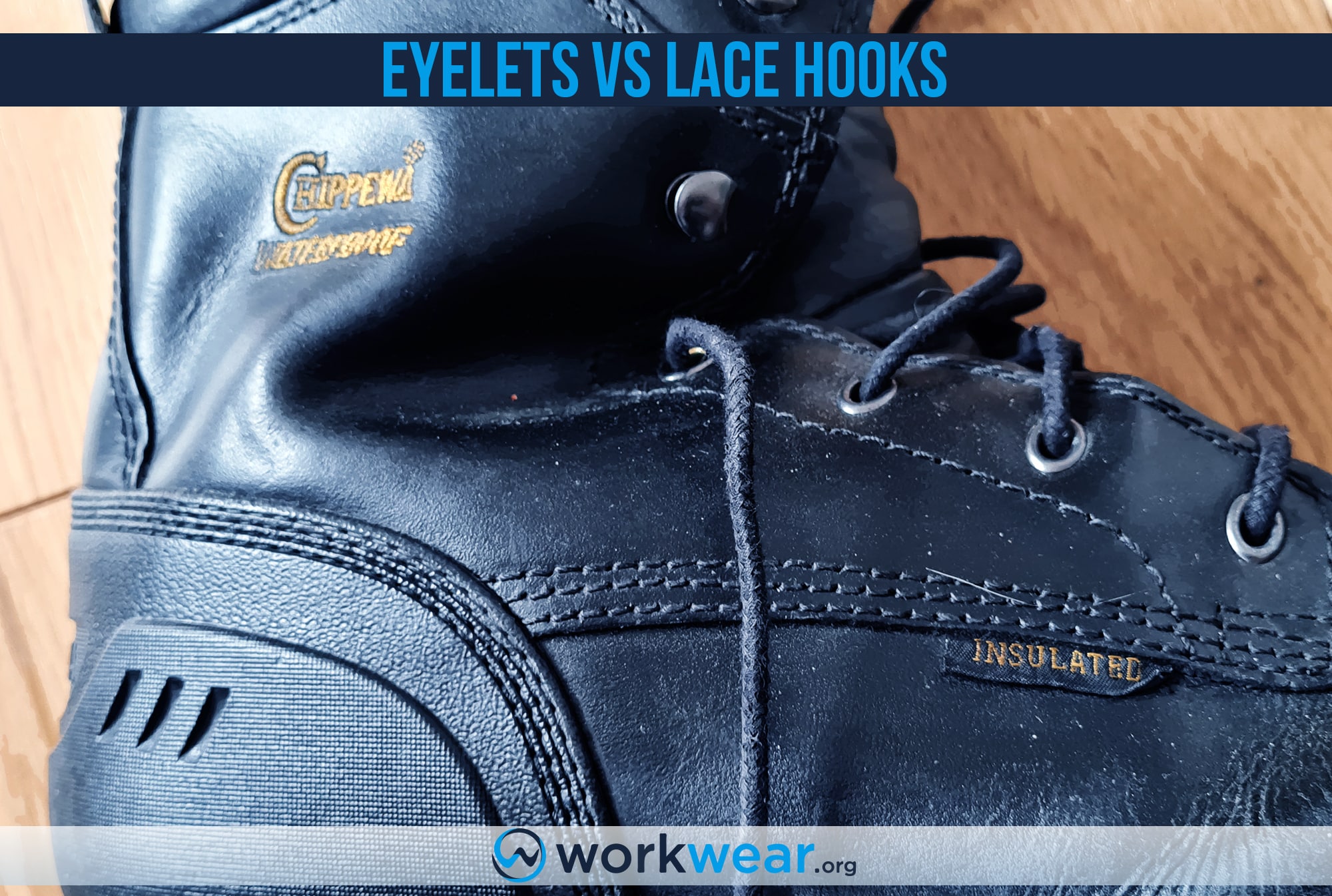

Lace Hooks

Lace hooks are another way of securing the shoelaces in place. They can also be considered a type of metal eyelet, although they don’t function the same way as those with punched or webbing designs.

Instead of being threaded through holes, the shoelaces are looped or wrapped around the hooks to maintain the desired boot fit.

Typically found at the top of the boot near the opening, lace hooks begin at the part of the upper or throat right above the last eyelet and often work together with eyelets – as seen in the Timberland PRO Pit Boss Steel Toe Work Boot. They’re also called “speed hooks” because they offer a much quicker way of adjusting or securing the laces than threading them into eyelets.

It’s worth noting that the speed comes at a price, as lace hooks are the least secure option for holding the shoelaces in place.

Key Advantages of Lace Hooks

- Sturdier than webbing eyelets

- Quicker shoelace fastening and adjustments compared to eyelets

Key Disadvantages of Lace Hooks

- Least secure option of holding the laces

|

Function |

Pros |

Cons |

|

|---|---|---|---|

| Eyelets |

Laces go through the holes/loops |

|

|

| Lace Hooks |

Laces wrap or loop around the hooks |

|

|

Conclusion

Eyelets and lace hooks are often overlooked, but they’re as important as bigger and more prominent parts of a work boot. They secure the shoelaces and adjust them accordingly, ensuring all-day comfort and walking stability. Eyelets are either punched into the top of the upper or take in a looped design, with both options enabling the laces to pass through so the boots’ fit can be adjusted and secured. However, they can take a lot of time to deal with. On the other hand, lace hooks hold the laces in place after they’re looped or wrapped around the metal component. These hooks offer a quicker way of lacing up, but they also offer the weakest way of holding the laces in proper positions.

FAQs

- Are there work boots with only lace hooks fitted in?

- No, most work boots come with a combination of eyelets and lace hooks working together for superior function. An example is the Redwing Iron Ranger, which has punched eyelets and lace hooks built into its structure.

- Do fabric webbing types of eyelets function well in work boots?

- Webbing eyelets made with fabric are typically fitted into sneakers and other footwear types. They’re not usually seen in work boots because they’re not designed for heavy-duty use and are prone to tearing or fraying more than punched eyelets.

- Why are blind eyelets more common in dress boots or shoes than work boots?

- Blind eyelets offer a more seamless appearance, which makes them suitable for dress footwear. They’re also more prone to tearing than punched eyelets with reinforcement materials on the front and back, so they’re unsuitable for work boots used in demanding conditions.

- What upper material works well with D-ring eyelets?

- D-ring eyelets are best suited for work boot uppers made with thick materials. This is because the metal rivets on the D-rings tend to press down on foot, and the thicker material of the upper can help protect the foot against significant pain.