S1, S2, and S3 Safety Shoes Explained by a Certified Safety Professional

Any workplace can have some residual dangers despite the best efforts of a business. Those dangers can be even greater if you work in an industrial or construction-based environment. With all the parts of your body that may need additional protection, your feet should be top of your list. This is where you will want to take a closer look at the safety shoes needed to ensure that your connections to the ground are kept healthy and protected.

This is where the S-type of safety shoes come in. They are safety shoes that are made to provide various levels of protection, comfort, and overall performance based on the hazards faced in your specific work environment. In this article, we will go through the different types of safety shoes protection and performance, and will explain the differences between S1, S2, and S3 classifications.

Types of Hazards to Consider

Safety shoes are going to be needed whenever equipment or environmental conditions can damage your feet. Some of these conditions can harm more than just your feet. For example, consistently wet environments (whether water, oil, or other source) can cause you to slip and fall. I cringe to think about how that can hurt, considering I’ve fallen myself.

You can also have hazards relating to falling heavy objects, sharp objects, high heat sources, and chemical and electrical hazards. The bottom line is that if your feet hurt, your work and personal life will be negatively affected. Have you ever twisted your ankle? If so, you know that a sufficiently hurt ankle or foot effectively reduces your mobility. You may need crutches or a medical boot if the injury is bad enough. Additionally, you can’t be as productive at your job after such an injury

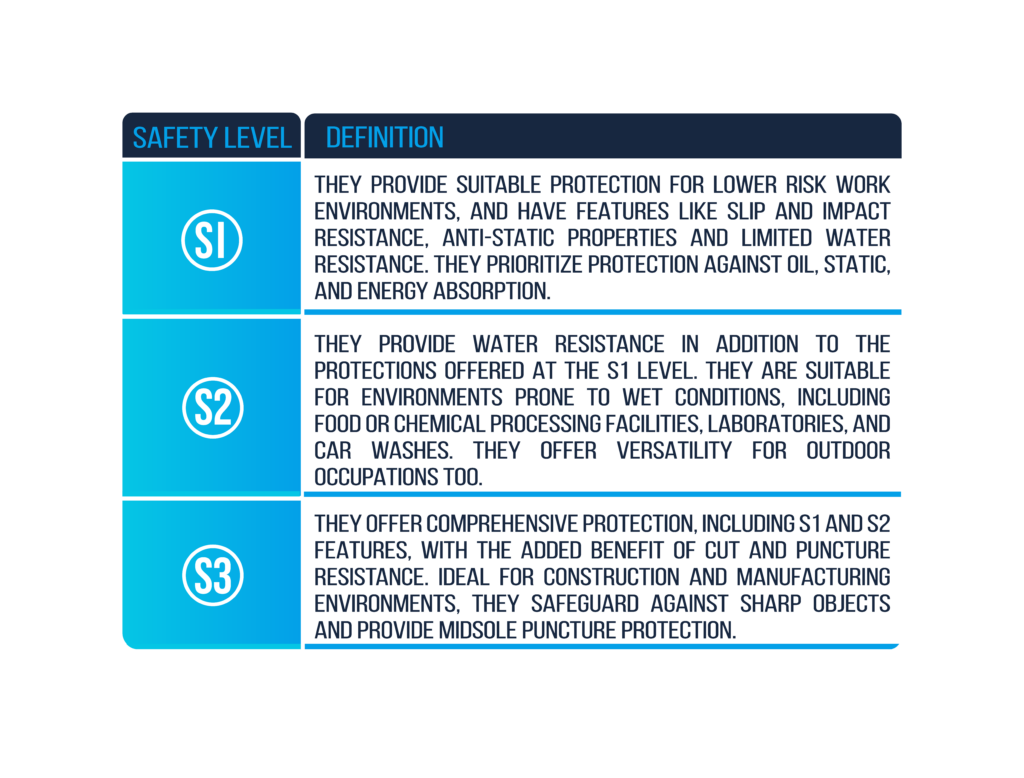

Explaining the Differences between S1, S2 and S3

Used often in the UK, safety shoes have three major classifications depending on the level of protection they offer. While there are other classifications, the common ones mentioned are S1, S2, and S3. These classifications are for relative levels of hazards in the workplace that are likely to be faced.

S1 Level Safety Shoes

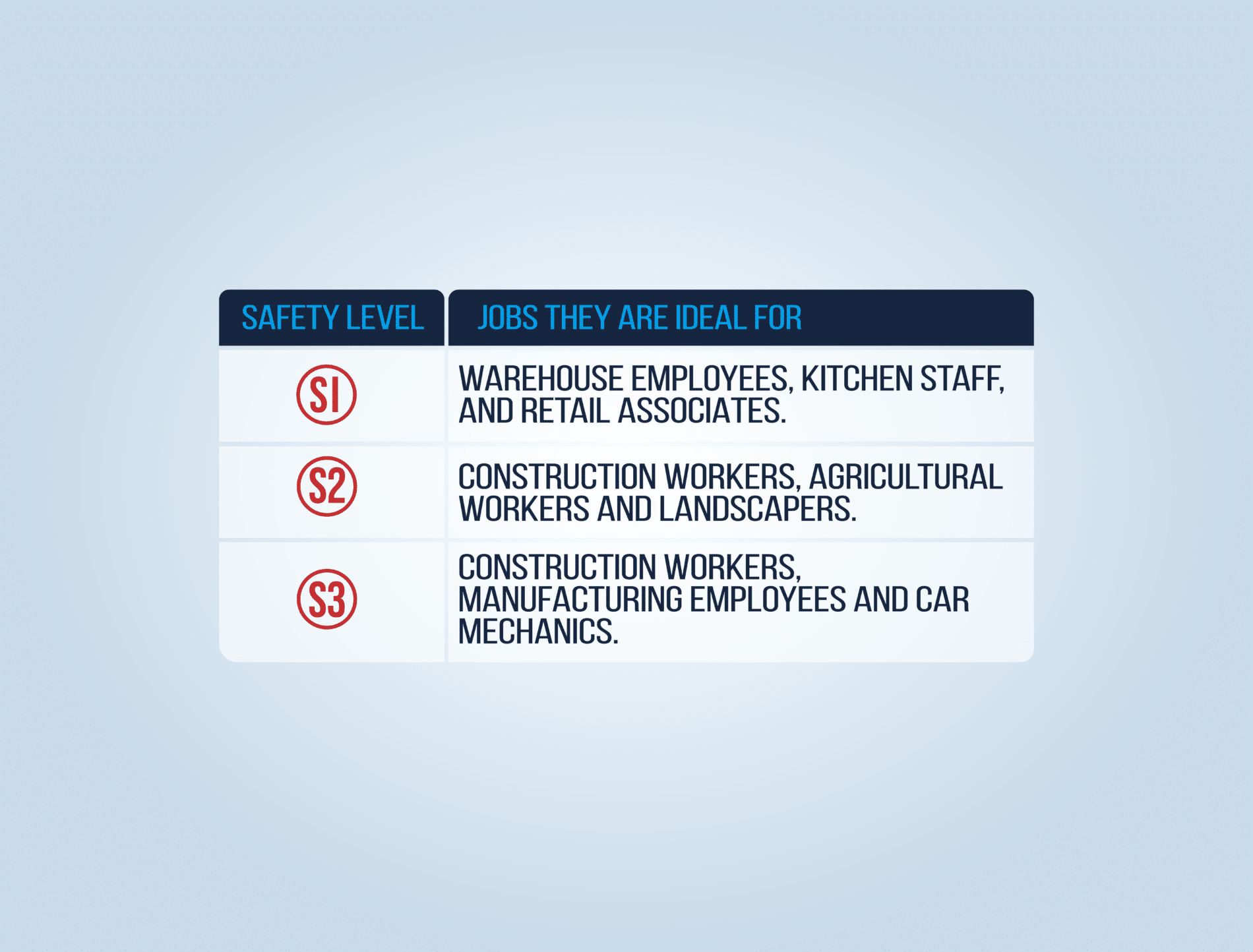

This level represents protection, meeting the needs of most lower-risk work environments. This would include workplaces such as warehouses, offices, call centers, kitchens, and similar workplaces. Common protection features for this level of protective footwear includes being slip resistant, resistant to impacts and being crushed, and they can be anti-static. This tends to make this level of footwear suitable for use in indoor environments that aren’t wet. They can also be used outdoors if there are minimal risks, but since this level tends to lack protection against water, they won’t do well in anything more than relatively light levels of moisture. Specifically, the protection focuses at the S1 level will include oil resistance/protection, protection against static, and energy absorption.

S2 Level Safety Shoes

At this level, the main feature will be water resistance. They will generally meet the protections at the S1 level and include protection against water. So, if you work in an environment that is prone to wet conditions, this will be the shoe you need. It will also work for many outdoor applications. Common jobs that this shoe can work for include many food or chemical processing facilities as well as some laboratories and car washes.

S3 Level Safety Shoes

The protection shoes at this level provide are needed in construction, manufacturing, and similar work environments. They offer the protection levels you get at the S1 and S2 classifications, and they offer the added benefit of providing protection against cuts and punctures. If you’ve ever seen some construction sites, boards with nails sticking out of them can be reasonably common things to find. I’ve seen the Home Alone movie, and I can tell you that I’d have no desire to have a nail go through my foot. That seems like a very bad day all around. You’ll be thankful for the midsole puncture protection footwear at this level provides if you work in these more hazardous environments.

Other Hazard Considerations

Remember earlier when I said there are many hazard considerations when choosing the correct work footwear? Well notice that these categories don’t necessarily cover all the hazards you may face. You may find that when you look at your particular work environment, safety shoes that are water resistant won’t cut it when working with extremely oily, corrosive substances. I’ve seen firsthand what can happen to general duty boots when they are not rated for the conditions they will go through. They can break down quickly.

So, the moral of this is to do a full PPE hazard assessment to ensure that you not only choose boots of sufficient S rating but that they also protect against any additional hazards that may not be covered in these three S ratings. Some examples of additional protection include chemical-resistant soles, heat-resistant/rated boots, metatarsal protection, electrical hazard protection, and being long enough and solid enough to muck around in deeper water or fluids. Don’t bring general duty footwear, even high-hazard ones, to a worksite requiring specialty protective footwear.

Maintenance, Care, and Comfort

Have you ever worn protective gear that was uncomfortable for long periods? How long did it take to stop wearing it, regardless of how needed it was? Well, it’s quite important to make sure your footwear protects against what you’re going to face daily and for those special jobs that require special footwear. But if you don’t get shoes or boots that you can be comfortable wearing for hours at a time, either your productivity will fall off or you will likely do something to the boots to make them more comfortable. That will probably compromise their safety to some degree.

Comfort

So, what makes comfortable footwear? Well, I’ve found that if you get boots that are shaped to your feet and are sufficiently wide don’t tend to hurt. Additionally, supportive insoles that are rated for heavy work use have served me well in my many years of industrial work. At the end of the day, there is no substitute for getting measured and trying shoes on. Listen to your feet. They tend to tell you what works and what doesn’t.

One thing you will probably find is that the more comfortable, higher quality shoes will be of a higher price. As the saying goes, you tend to get what you pay for. While safety shoes can be expensive (what isn’t these days?), you should invest in getting a pair that will help and not hinder you. Thankfully, employers often foot at least a significant portion of the bill towards this essential form of personal protective equipment.

Maintenance and Care

If you expect your footwear to serve you well, you need to take care of it. For starters, you need to clean them regularly. This serves at least two purposes. Depending on your workplace, you can have damaging grime that can shorten the protective lifespan of your footwear, even if it’s resistant to said grime. Remember that resistance is not immunity. The second reason you clean your shoes is to see if you can find any damage. If they get sufficiently damaged, then it’s time to replace them. But you won’t likely see said damage if you never clean them, will you?

Safety shoes may come with care instructions. Give these a look at how the manufacturer recommends you care for your shoes to maximize their useful life. I don’t know about you, but I’ve seen the damage that sunlight can do to materials when left out in it for long enough. So, don’t store your shoes in the sunlight when not in use. It’s wise to keep them out of moisture when not in use, allowing them to dry out after they’ve been sufficiently cleaned of the goop and grime of your workday.

I’ve said this before, but it needs to be repeated. If your safety shoes are damaged, get them replaced. If your safety toe is made of composite material and successfully protects your foot from harm, great! It’s done its duty. And it’s likely done now. Don’t tempt fate.

Summary & Key Takeaways

Safety shoes are an important investment in protecting what carries you around, which are your feet. While there are many considerations for getting adequate protective footwear, the S safety level classifications can help make that choice easier. So, let’s look at the key things to remember from this article.

- Do a PPE hazard assessment to determine the hazards in your workplace and for your jobs/tasks.

- S1 level safety shoes have anti-static properties, impact resistant/energy absorbing, and are oil resistant (which can help with slips).

- S2 level safety shoes have S1 level protection as well as being water resistant. These are good in outdoor environments and other wet environments.

- S3 level safety shoes provide S2 level protection as well as having a puncture resistant midsole.

- Make sure to get comfortable shoes that fit you, and you can wear them for hours.

- Make sure to take care of your safety shoes by cleaning them, storing them in dry environments away from heat and sunlight, and replacing them if they get sufficiently damaged.

- Resistance is not immunity from damage. Just because you have some protection doesn’t mean you should get cavalier with your safety.