Western Boot Parts Terminology

When you want to add a stylish element to your outfit, Western boots give you a chance to do so effortlessly. These boots are also built with strong structures, with some styles enhanced with features that make them suitable for work. Only some people are familiar with the anatomy of a Western boot, though, and reading through the boot’s description can be quite confusing. If you’re looking to add Western boots to your ensemble, it’s important to know the terms used for the different parts that make up the footwear. Becoming familiar with the terminology will make it easier for you to find the Western boots that will give you the greatest benefit, especially when you discover what the terms mean and how each part functions.

Key Takeaways

- Western boots have different features than other boot styles, so the terms used for their parts vary significantly from other boots.

- These boots often showcase intricate stitching and accents, making them fantastic choices if you want to add an eye-catching element to your outfits.

- While the terms referring to the basic structure of the boots are the same, there may be unfamiliar terms that point to the decorative aspect of Western boots.

- Knowing the terms used for the parts of Western boots can bring better appreciation for their benefits. The knowledge can make it easier to choose the best options that match your requirements.

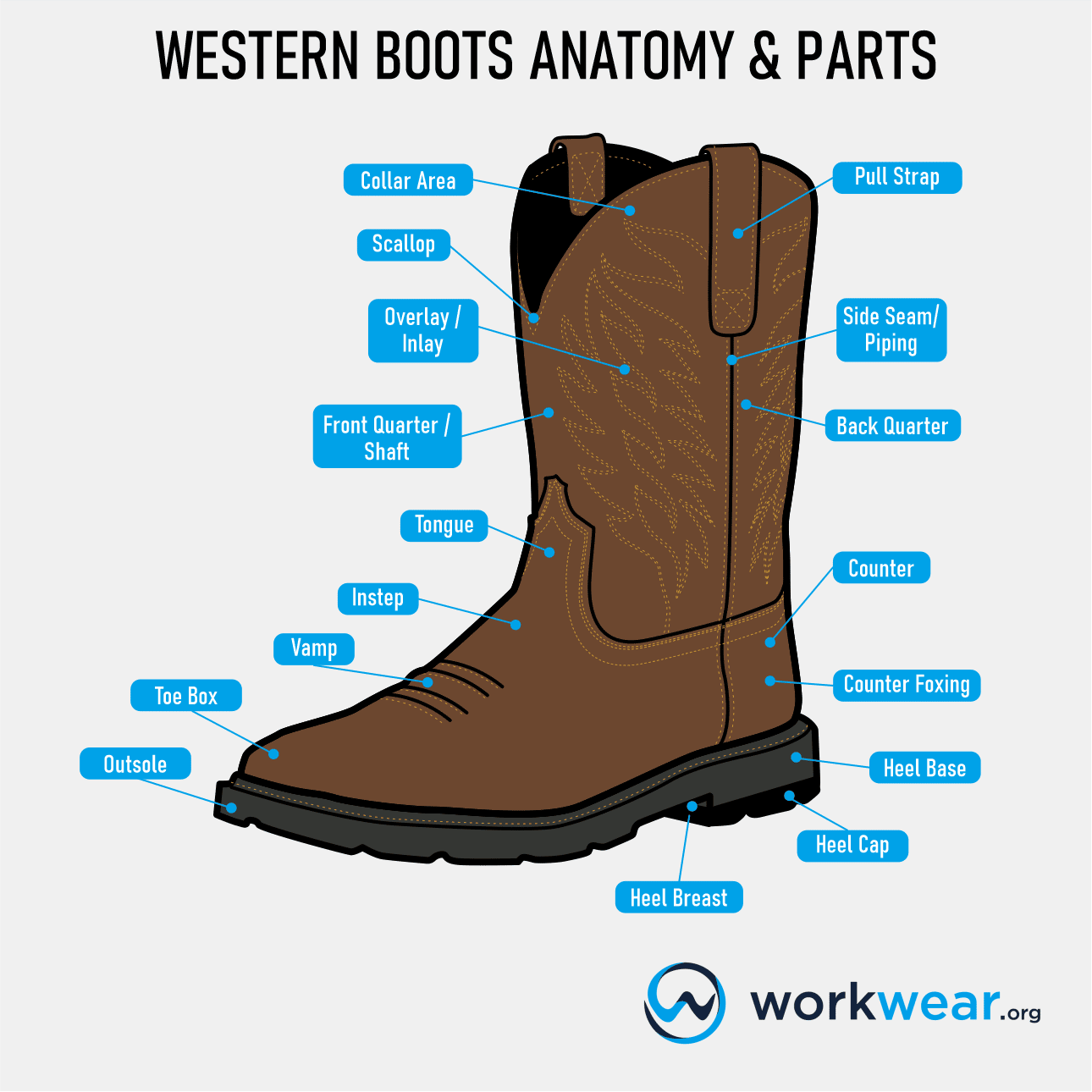

Western Boot Parts

These are the parts that make up a Western boot.

Upper

The following components are included in the uppers of Western work boots.

Shaft

The shaft is the part that covers the ankle and lower leg, looking like a cylindrical structure that wraps around the calf.

Western boots have a distinctively high shaft that goes at least to the middle of the calf and typically has a height of 10-14 inches. The shaft design can vary widely, with some featuring decorative perforations or intricate stitching, although there are also some Western boots with plain shaft portions.

Scallop

The scallop refers to the part of the boot opening which dips toward the middle, forming a V shape in the front and back portions of the boot’s shaft. This scalloped detail gives Western boots a unique appearance, making them easy to distinguish from other boots with high shafts – such as traditional English riding boots. Aside from the aesthetic benefit, the scallop also offers functional advantages, making the boot easier to put on even with the tall shaft. With the scalloped structure, the opening becomes wider, accommodating the foot with less trouble than a completely circular boot opening. In addition, the scallop also prevents the boot’s opening from digging into the front of the leg with every step for a more comfortable experience.

Vamp

The vamp is the boot section that goes over the top of the foot. It’s the most visible part when pants are worn over the boots, and the fabric covers most of the leather upper.

This is why it’s important to choose Western boots with a vamp that looks most appealing to you, as this is the part that you – and other people – are likely to see most often.

The vamp can be embellished with stitching patterns, but it can also be left plain to showcase the richness of the leather.

Collar

The collar area is the section at the boot’s opening, including the stitching on top near the edge and the leather material. In Western boots, the collar is just below the scalloped edge and can include the parts where the pull straps are stitched into the leather. The collar can be left plain, but some boots also have decorative stitching in this area.

Overlay/Inlay

An overlay or inlay refers to the additional material placed on the boot’s shaft. It’s often made from a material different from the one used in the rest of the boot, providing contrasting textures, details, and sometimes colors to give the boot a more eye-catching look. In addition, some inlays or overlays come with different colors and stitching accents to give the Western boots an even more striking aesthetic.

<<yellow box>> It’s worth noting that these additional materials, and the way they’re placed on top of the upper, may increase the risk of damage to the boots. This is because the raised embellishments are more prone to catching on surrounding objects and are often the first to become frayed.

Front Quarter

The front quarter refers to the front portion of the shaft. In some cases, the back and front parts are collectively referred to as the “shaft,” but there are times when these two portions are separately considered because they have different designs, accents, or textures.

Back Quarter

The rear quarter is the portion of the boot’s shaft at the back. The front and back quarters can have completely different appearances, hence the need to differentiate them. However, in Western boots, the front and back portions mirror images; these two parts are referred to as the shaft.

Side Seam/Piping

The piping or side seam refers to the rounded strip of material or stitching on the side of the shaft, running throughout the entire height of the boot. It’s used to cover the exposed edges of two separate pieces of leather that are stitched together to form the boot’s shaft. Only some Western boots have side seams or piping, which can be seen in most styles.

Embroidery/Decorative Stitching

Western boots are more eye-catching with the addition of elaborate stitching, making them stand out from other types of boots.

The embroidered details are usually showcased on the boot’s shaft, but they can also be spread over the vamp and even the collar area.

The stitching outside Western boots was originally meant to keep the leather from folding or wrinkling, which causes discomfort when from inside the boot when it rubs against the leg. It also served to keep the leather parts strongly attached. Now, decorative stitching also increases the stylish appeal of Western boots. The embroidery can be made with threads having the same color as the shaft for a low-key accent, while the elaborate styles feature stitching of various colors and more intricate patterns.

Tongue

The tongue refers to the portion of the Western boot where the vamp and shaft meet. It often features strong stitching to reinforce the attachment between the two leather boot parts and can also include decorative stitching as accents.

Instep

Inside the boot, the instep is the part that touches the top of the foot. It helps maintain the structure of the boot when it’s worn and even when it’s not used.

The instep also greatly impacts comfort – it’s too tight, can make walking uncomfortable, and make the boot challenging to put on and remove. On the other hand, an instep that’s too loose will not support the foot’s proper position and cause unwanted movement, which can result in unstable walking. Since Western boots don’t have laces for fit adjustments, it’s up to the instep to keep the foot firmly in place.

Counter

Also called the heel counter, this part is located on the lower back portion of the boot where the heel is positioned. This portion is typically harder than other parts of the boot, with the additional rigidity working to secure the heel. The counter helps stability by preventing the foot from sliding inside the boot, especially while walking on uneven surfaces.

Counter Foxing

The counter foxing is the material placed just outside the heel counter. This overlay protects the heel area from scuffs and scratches, often made with the same material as the rest of the upper so it blends seamlessly into the boot’s.

Toe Box

The toe box is the part of the boot that maintains the structure at the tip. It houses the toes and keeps them protected against abrasion and is also the portion of the boot that’s most likely to get scuffed and scratched first because of its position. The toe box is designed to have a rigid shell not only for toe protection but also to maintain the structural strength and high-quality appearance of the boot at the tip. In addition, it can be enhanced with safety toe caps for even better protection against dangerous compression and impact.

Safety Toes

Traditionally, Western boots didn’t have safety toes as they weren’t meant for use in hazardous work settings.

Now, some Western work boots are equipped with safety toe caps that protect the toe area against serious injuries, which may be caused by heavy objects, such as pieces of machinery or tools, that drop from elevated spaces.

These boots’ safety toe caps can have metal (such as steel or aluminum) or nonmetal materials – such as fiberglass or carbon fiber – which are strong enough to guard the toes upon exposure to dangerous impact or compression.

Pull Strap

The pull strap is fitted into the top of the shaft at the back, close to the boot’s opening. It typically looks the same and is made from the same material as the rest of the shaft, but some pull straps can be made with a different color or material, either for enhanced aesthetics or better function. In addition, the pull strap aids with a quicker boot on and off, especially since Western boots don’t have laces that can loosen to help accommodate the feet’s entry.

Sole

These are the components of a Western boot’s sole.

Insole

Inside the Western boot, the insole is the part directly in contact with the sole. It sits on top of the midsole and provides a soft base for the foot to rest on. Depending on the materials, the insole can deliver ample cushioning for superior comfort. Insoles with breathable materials help keep the boot interior cool for longer and prevent overheating after hours of use. Insoles can be attached to the boot’s structure or removable, with the latter being easier to clean and replaceable for a better fit. Those with a curved structure or extra cushioning can help improve arch support for pain relief.

Midsole

As the name suggests, the midsole is positioned between the insole and outsole. This component often works as the boot’s main shock absorber, taking in the impact of continuous steps and dispersing it before it turns into discomfort. It also adds another layer of cushioning to keep the foot comfortable even after a long day of standing or walking. In addition, some Western work boots are equipped with puncture-resistant midsoles, with materials such as Kevlar fitted in to help protect the feet from the bottom against serious puncture injuries.

Outsole

The outsole structure forms a protective base and is the component that’s always in contact with the ground. Western boots with traditional styles are often built with leather soles, just like dress shoes, to give the boots a classic, premium aesthetic. However, leather soles may feel more comfortable for some, with the breathable material molding to the shape of the foot over time for a customized fit.

However, leather soles aren’t strong enough to withstand heavy use in challenging conditions and don’t offer a firm grip on tricky surfaces.

Meanwhile, rubber soles can make Western boots look bulkier – but they last longer, offer stronger traction and abrasion resistance, and deliver higher shock absorption for enhanced comfort.

Shank

The shank is a thin piece of material built into the boot area between the insole and outsole. It works to reinforce the arch and the boot’s structural integrity for improved stability while walking. The shank can be made from metal or composite (nonmetal) materials.

Heel

Western boots are easily distinguished from other work boots because of the stitching accents and high shaft, and pronounced heels.

Traditional Western boots have heels built with compressed leather and are originally meant to keep the feet securely positioned in the stirrups while going horseback riding. On the other hand, more modern styles designed for work feature heels made with the outsole’s material – which is often rubber.

Different types of heels can be fitted on Western boots, and these types can be categorized according to height, each one serving a specific purpose.

Heel Base

The heel base refers to the part of the heel that’s crafted from the same material as the outsole. It’s the portion directly below the welt stitching and is built to be thick enough to support the boot while offering a height boost to the wearer.

Heel Cap

The heel cap refers to the cap that covers the bottom of the Western boot’s heel. It’s usually made from a material different from the one used on the heel – except for Western work boots with all-rubber outsoles and heels. The heel cap often uses rubber or other grippy materials to add traction, making the heel more resistant to slipping so walking can become more stable over different surfaces.

Heel Breast

The heel breast is the front side of the heel closest to the middle part of the outsole. It offers a seamless look from the bottom of the boot as the outsole blends into the heel.

Welt

The welt is the stitching that ensures a strong bond between the vamp and the outsole. In Western boots, a full welt refers to the stitching that goes throughout the perimeter, including over the heel. On the other hand, a three-quarter welt refers to the perimeter stitching that encompasses the front portion to the areas under the arches on both sides. The welt is called single-stitched if it comes with one row of visible stitching and double-stitched if the stitching is done in two visible rows.

Conclusion

Knowing the terms used for Western boot parts can make it easier to appreciate what the components are for – and how their function benefits you as the wearer. It’s easy to assume that the terms used for Western boots are the same as the ones used for other types of boots. However, these boots have different features from other boot styles, so the terms vary significantly. For example, as discussed, the parts that make up a Western boot’s upper are the shaft, scallop, vamp, collar, overlay or inlay, front quarter, rear quarter, side seam or piping, embroidery or decorative stitching, tongue, instep, counter, counter foxing, toe box, safety toes, and pull strap. On the other hand, the sole comprises the components: insole, midsole, outsole, shank, heel, heel base, heel cap, and welt. Knowing what these terms refer to makes understanding how each component can help with the boot’s performance easier. The knowledge can also help make the boot selection process much easier, especially if you get to know which parts can help you walk and move more efficiently as needed.

FAQs

- Is the traditional Western boot heel suitable for work settings?

- No – in general, Western work boots have lower heels. Traditionally, Western boot heels are 1.5 inches or higher, but the boot styles for work generally have lower heels (such as the 1-inch roper heel) for better performance and stability. Higher heels found in traditional Western boots are more appropriate for horseback riding.

- Do all Western boots have to pull straps?

- Some Western boots have to pull holes instead of pull straps. These holes are also designed to help the wearer easily pull on or remove the boots. They also add a decorative touch to the boot’s collar.

- Are leather soles the best for Western boots?

- It depends on how and where the boots will be used. Leather soles are ideal if the boots are used for settings that require dressy or formal-looking footwear. These soles are also great for indoor workplaces that aren’t exposed to wetness and slippery surfaces. However, leather won’t work well for outdoor conditions where the ground is rocky, rough, or uneven. In this case, rubber outsoles will perform much better as they deliver a stronger grip for improved safety. The rubber outsoles will also be sturdier and handle tough conditions better than leather soles.

- Do all Western boots have high heels?

- No – although Western boots are often pictured with distinctively angled high heels, some have roper heels around 1 inch in height. These lower, squared-off heels are easier to walk in and ideal for work. Meanwhile, the higher heels that are around 2 inches or taller are best for riding since they keep the boot secured in stirrups.