What is PPE? Explained, demystified and illustrated!

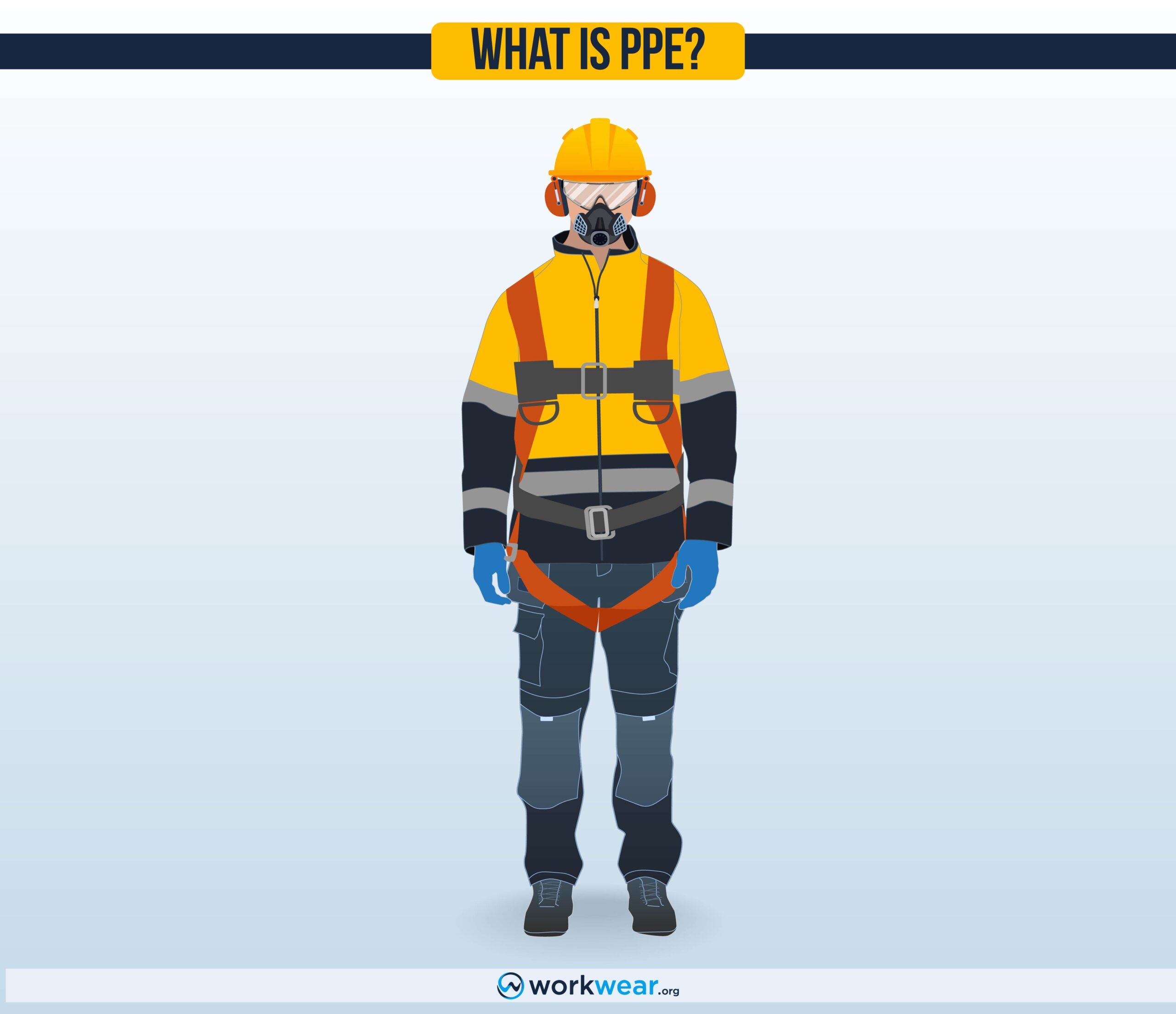

Personal protective equipment (PPE) is a critical aspect of workplace safety, designed to protect workers from hazards that they may encounter on the job. PPE includes any equipment that is worn on the body to provide protection from physical, chemical, biological, or radiological hazards. While PPE is an essential tool for minimizing risk, it should be viewed as the last line of defense in the hierarchy of controls, which prioritize hazard elimination, substitution, engineering, and administrative controls.

PPE can vary significantly depending on the specific hazards involved in a particular job. It is not a one-size-fits-all solution, and its effectiveness depends on its proper use and suitability for the job. Although PPE is an important aspect of workplace safety, it has its limitations and should not be relied upon as the sole means of protection. The goal of workplace safety is to ensure that employees can perform their duties without injury, and PPE is just one of the many tools available to help achieve this goal.

The Hazard Assessment

It’s extremely important to assess the hazards in your workplace. This is true generally, but this applies to PPE in particular. You may be asking why this is the case. For example, how well do you think impact-rated safety glasses that are fairly open in design will protect you from fine dust? The answer is they won’t do much of anything to protect you. Another example would be respiratory protection. A respirator that is good at filtering out the fine particulate matter but doesn’t protect against the organic vapors you’re being exposed to will also be pretty useless.

When assessing workplace hazards, you will look at various exposure types. Depending on the specific work environment, employees might face any (or more) hazard types: mechanical, biological, chemical, thermal, and electrical. These are some of the more common hazard types. After identifying which hazard types you have in your workplace, you have to see how they manifest. For instance, mechanical hazards include but are certainly not limited to cuts, punctures, abrasions, and contusions from blunt forces.

Helpful Resources

Now, there is a lot to assessing the hazards and choosing the right PPE. And there’s some truth to that. But you don’t have to figure out everything on your own. For instance, if you are dealing with chemicals as part of your operations, there are information sheets called safety data sheets that contain important information about the specific chemical. Guess what one such piece of important information is? You guessed it! It’s got information on the PPE you should use for handling the chemical. That will make it much easier to identify suitable equipment to protect against that chemical.

Additionally, the Occupational Safety and Health Administration, or OSHA for short, have standards that detail the types of work that may require specific PPE. For example, the electrical standard will show that electrical PPE will be needed when there is unprotected exposure to energized electrical equipment. Such standards either give the specific PPE requirements or reference another standard that details what specifications PPE must meet when required.

The Right Tool for the Job

It can’t be stressed enough that you need to pick the right PPE for the right hazards. But it would help if you chose the right PPE for the job. It’s similar to picking the right tool for the job. If the PPE doesn’t protect your employees, you’re rolling the dice until both the employee and the company are having a bad day. But employees aren’t likely to wear the PPE consistently, or at all, if the PPE is either uncomfortable or causes some problems.

No matter how protective your work glasses are, if you go from a warm, humid environment to a cold, dry environment, your glasses might fog up. How much work do you suppose someone will get done when they can’t see their hand in front of them? My guess would be not very much. If the provided work boots are cheap and uncomfortable for employees, do you think they’ll be particularly motivated to continue working efficiently? I know it has bothered me to work long hours in boots that weren’t comfortable in my manufacturing career. I don’t advise anyone to do the same.

PPE is often as different as the needs of the people who wear it. So, don’t categorize safety and the work to be done. You don’t need to get the work done OR be safe in the workplace. The goal is to get the work done AND be safe while it’s being done. Putting in the effort upfront can mean more productive, profitable time and less time scrambling to respond to an emergency. Consider your PPE workplace hazard assessment an investment in your people and your company.

A Foray Into PPE

Tips for Selecting and Managing PPE

Your workplace is complex. Selecting the right PPE can be critical. So, how about some tips to steer your selection process in the right direction?

- Like your body or your company, PPE can be interconnected.

- You may need head protection and face protection for a welding job. A standard welding hood may not fit a hard hat. So, get a welding hood that can fit your hard hats.

- Some PPE can offer protection against multiple exposures. Seek them out where possible.

- They make gloves capable of protecting against cuts, punctures, oil, and water.

- Don’t go overboard with internal PPE requirements unless you are prepared to enforce them.

- No one wants your employees to roll an ankle in their work boots. But are you prepared to check to make sure they always tie their laces? Or are slip-on and zip-up boots just as effective with less work? Make sure to consider such things.

- Be prepared to track and inspect PPE in the field.

- Some employees lose PPE all the time. Some will wear PPE until it is not useful or protective… and still not request replacements. I can tell you that seeing perfectly good PPE lying in the mud will not go over well with management.

- Select where you will store it and how you will track the inventory.

- PPE won’t do any good if you don’t have it. You and any supervisors must know where to get it and any methods used to track the inventory count. You need to know when to order more. While the last minute is a popular option, it isn’t advised.

Main Types of PPE

Each workplace is at least a little different. Those differences may be enough to change the PPE needed to do the work greatly. That said, some forms of PPE will be very common due to the great use of the body parts they protect or the sensitivity of certain body parts to be irreversibly damaged. Your hands and eyes fit those respective descriptions.

Thinking of the various industries I’ve seen or worked in, the common ones that come to mind are as follows:

- Eye and face protection

- Foot protection

- Hand protection

- Head Protection

- Respiratory Protection

- High Visibility Clothing

We’re going to get to take a look at these common PPE types. And some of the advice given to help make sure they last a long time will be similar across types. After all, keeping anything clean and in good condition helps it to last.

-

Eye and Face Protection

Whether you work on a manufacturing floor, a restaurant, or a lab, you will need eye and face protection. Examples will include impact-rated safety glasses, chemical splash goggles, dust rated safety glasses, clear face shield, and shaded face shields. However, if you want to make sure your eye and face protection will be effective and go the distance in terms of longevity, you’ll need to ensure a few things.

Care and Compliance Guidance

- Eye and face protection needs to meet the current ANSI Z87.1 standard

- Eye and face protection must be kept clean as well and sanitized

- Eye and face protection needs to be free of cracks or deformities.

- That means you have to inspect them.

- That also means it has to be clean enough to see the damage.

- They can’t work well if they aren’t in sound condition.

-

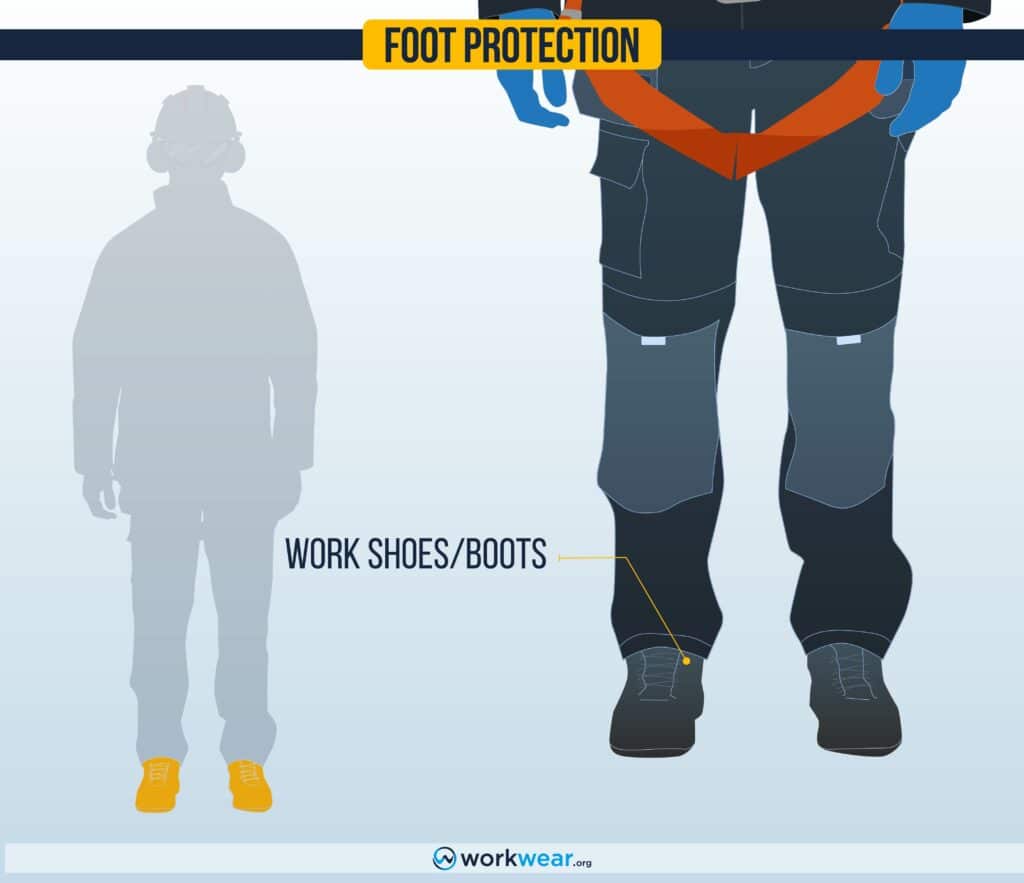

Foot Protection

It should be no surprise that foot protection made this list. Most of us wear shoes, after all. Why do you think that is? There are several hazards associated with walking, plain and simple. Foot protection may have many different specific protections, such as safety toes, metatarsals, slip resistance, chemical resistance, and electrical hazard ratings, to name a few. Here’s what you need to do to make sure your footwear protects you so you can, you know, keep walking around.

Care and Compliance Guidance

- Just as was the case for eye and face protection, there is a standard for foot protection. It must meet the current ASTM F-2412 and ASTM F-2413 standards for foot protection testing methods and performance requirements.

- Clean your shoes off after using them and inspect them for damage or defects. Do it in that order.

- Make sure you wear your shoes correctly. If they have laces, lace them up. If they have a zipper, zip them up.

- Make sure to choose well-fitting, comfortable shoes in the first place. You will spend a lot of time in them.

-

Hand Protection

You use your hands an awful lot. So, you better pick the right gloves for the right hazards. Some expected hazards come from heat, cuts, punctures, and chemicals. In some cases, you can blend multiple protective qualities in one glove.

Care and Compliance Guidance

- Get gloves that fit your hand.

- If they develop holes in them, it’s time to replace them. Heat, chemicals, and general hazards have this pesky way of finding vulnerabilities in things.

- Clean and inspect your gloves often.

- Choose gloves with multiple protections when warranted.

- Some gloves protect against oil, water, arc flashes, cuts, and punctures.

- Your gloves are not invincible and do not replace machine guards.

-

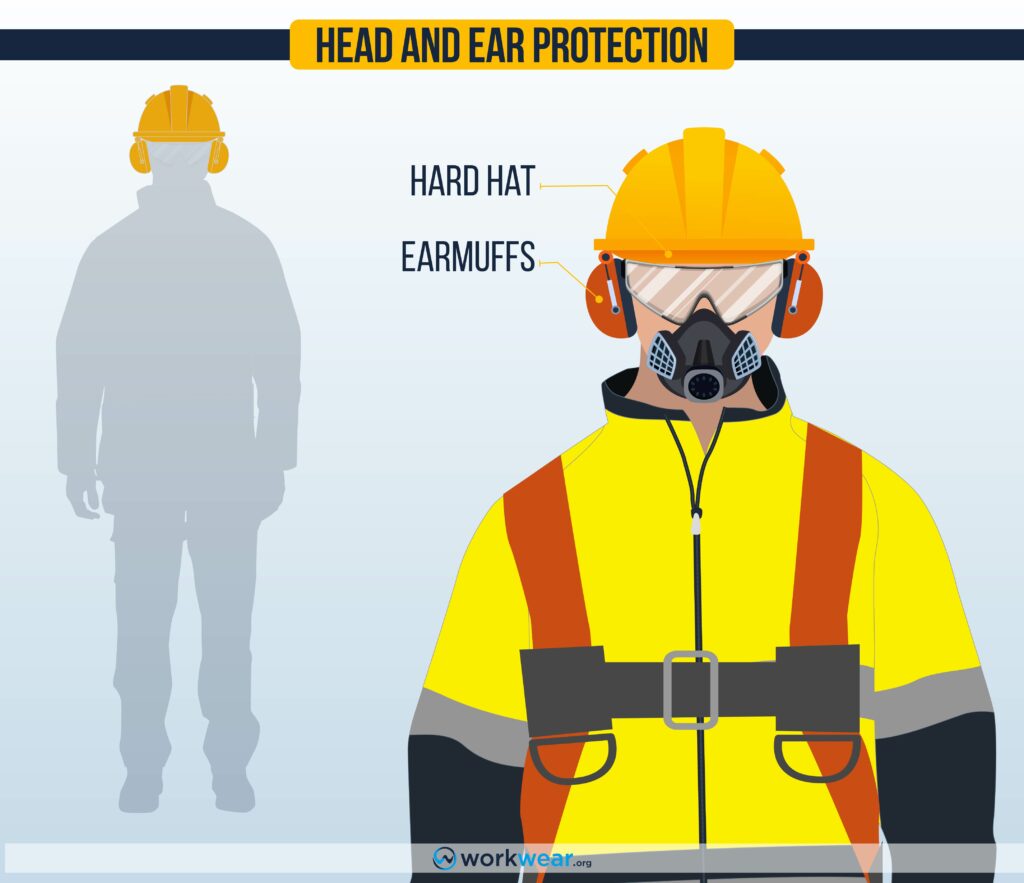

Head Protection

The hard hat is one of the most iconic types of head protection. Typically, head protection protects against bump and falling material hazards. They can also be rated to provide some protection against overhead electrical hazards, such as power lines. If you take the time to search for them, you can find head protection that integrates with other protective items, such as a face shield.

Care and Compliance Guidance

- Head protection must meet the current ANSI Z89.1 standard or equivalent.

- Clean and disinfect head protection, especially if worn by more than one person.

- While you may have to spend much time outside and in the sun, store head protection away from sunlight when not in use.

- I don’t know about you, but I’ve seen what the sun can do to plastic if you leave it in it for a long time. It tends to crack and crumble.

- Replace the suspension every twelve months and replace the shell every five years.

- The head protection instructions are a good place to look for these requirements.

- You’ll want to put some stickers meant for hard hats under the brim so you can know when to make the applicable changes.

- Don’t cover the hard hat with a lot of stickers. They can hide defects and damage.

-

Respiratory Protection

In certain work environments, respiratory protection may be necessary to protect against airborne hazards such as dust, fumes, gases, and vapors. The type of respiratory protection needed will depend on the specific hazards present in the workplace.

Care and Compliance Guidance

- Respiratory protection must meet the current OSHA respiratory protection standard (29 CFR 1910.134) or equivalent.

- Choose the appropriate type of respirator for the specific hazard present in the workplace. This may include filtering facepiece respirators, half-mask respirators, or full-face respirators.

- Make sure the respirator fits properly and creates a secure seal against the face. Fit testing should be conducted to ensure a proper fit.

- Inspect the respirator before use to ensure it is in good condition and free of defects.

Clean and sanitize the respirator after each use according to the manufacturer’s instructions. - Replace the respirator cartridges or filters as necessary, based on the specific hazards present in the workplace and the manufacturer’s recommendations.

- Ensure proper storage and maintenance of the respirator to ensure it remains in good condition and is readily available when needed.

-

High Visibility Clothing

In certain work environments, high visibility clothing may be necessary to protect against potential hazards and improve worker visibility. The type of high visibility clothing needed will depend on the specific hazards present in the workplace and the lighting conditions.

Care and Compliance Guidance

- High visibility clothing must meet the current ANSI/ISEA 107 standard or equivalent.

- Choose the appropriate type of high visibility clothing for the specific hazard present in the workplace. This may include vests, shirts, jackets, or pants.

- Make sure the high visibility clothing fits properly and is comfortable for the worker to wear. Poorly fitting clothing can be a hazard in itself.

- Inspect the high visibility clothing before use to ensure it is in good condition and free of defects. This includes checking for holes, tears, or other damage.

- Clean and launder the high visibility clothing according to the manufacturer’s instructions. Do not use fabric softeners, bleach, or other chemicals that may reduce the clothing’s visibility or performance.

- Replace the high visibility clothing as necessary, based on the specific hazards present in the workplace and the manufacturer’s recommendations.

- Ensure proper storage and maintenance of the high visibility clothing to ensure it remains in good condition and is readily available when needed.

- Don’t wear high visibility clothing under other clothing, as this can reduce its visibility and effectiveness. Instead, wear it over other clothing or as a standalone garment.

- Provide appropriate training to workers on the proper use, care, and maintenance of high visibility clothing to ensure they understand its importance and can use it effectively.

Don’t wear ball caps or any other item not designed to be worn under a hard hat. This can diminish or negate some of the hard hat’s protective qualities.

Job Types and the PPE They Need

Guess what? You’re in luck! You get to see what some real-world jobs need for their general PPE needs. Of course, there are many job types, so you won’t get an exhaustive list. But these are some common ones.

Industrial field jobs

In industrial field jobs, employees are often exposed to various hazards, such as falling materials, sharp objects, and thermal hazards. To protect themselves, they need to wear appropriate PPE, including hard hats, safety glasses, safety boots, high visibility apparel, long pants, long sleeve shirts, and work gloves.

These safety items are necessary to ensure the safety of workers in industrial field jobs. By wearing PPE, workers can reduce their risk of injury and stay safe while performing their job duties.

Food services

PPE needed in food services varies based on the task. Slip-resistant shoes are essential to avoid accidents on wet floors, while cut-resistant gloves protect when slicing meats. When handling food, gloves such as latex or nitrile are necessary. Aprons and heat-resistant gloves are a must when handling hot, liquid food items. Finally, hair or beard nets prevent loose hair from falling into food.

Electricians

Electricians face significant hazards when working with electricity, including the risk of electrical shock and arc flash incidents. To protect themselves, they need to wear appropriate personal protective equipment (PPE). This includes arc flash-rated clothing, electrically rated gloves, an arc flash-rated hard hat and face shield, electrical hazard-rated safety shoes, and safety glasses suitable for electrical hazards. By wearing this PPE, electricians can reduce their risk of injury and safely perform their work.

Medical professionals

Medical professionals require different types of personal protective equipment (PPE) to protect against potential hazards associated with their job tasks. Common PPE includes nitrile or similar sterile examination gloves, medically rated splash masks, safety goggles or chemical splash-rated safety glasses, coveralls and booties, and lab coats, coveralls, or aprons. The specific PPE needed will depend on the requirements of the job tasks, but it is essential to wear the appropriate PPE to prevent exposure to infectious materials and other potential hazards.

Firefighters

Firefighters face a wide range of hazards, including thermal and radiant exposure, punctures, abrasions, cuts, impacts, and respiratory hazards. To stay protected, they need to wear the appropriate personal protective equipment (PPE).

This includes layered garments and gloves to protect against most physical, radiant, flash, and thermal hazards while still allowing for some mobility. They also need a helmet to protect against impacts, boots rated to offer similar levels of protection to the garments, and a self-contained breathing apparatus (SCBA) that provides clean air to breathe in smoke-filled environments.

The Proper Use, Care, and Replacement of PPE

For starters, PPE won’t do you a bit of good if employees don’t use it. Hopefully, that’s a no-brainer by now. But PPE isn’t indestructible. They are rated to only take so much, and some components may have a shelf life. I can tell you that you don’t want to be the person using a fall protection harness and lanyard that hasn’t been inspected in who knows how long and looks to be in questionable condition. You better not fall, is all I’m saying.

As for gloves and high visibility vests… well, gloves don’t protect you too well if you have worn holes. And as for the vests, if they have become darker than your regular clothes or you are wearing them under your clothes, they are useless. Part of ensuring the proper use of PPE is to provide suitable training on how to use the PPE. But in the case of the high visibility vests, a person could be properly wearing the vest per the training, but the training didn’t specifically say to wear it so it can be seen. You may think this is obvious, but I’m telling you that it isn’t in some cases. When it’s rainy outside is when you might see something like this.

So, if you want to ensure that your employees are properly using, caring for, and replacing their PPE, this is what needs to happen with regularity:

- Management to ensure proper training is performed for employees on the general requirements for PPE and how to maintain specific PPE they may be assigned.

- Respirators must be cleaned, sanitized, and inspected for defects or damage.

- Safety glasses need to be cleaned and inspected for damage.

- Gloves need to be cleaned and inspected for damage.

- (Insert X PPE) needs to be cleaned and inspected for damage. Seeing a pattern?

- Management ensures routine observations are performed to verify that appropriate PPE is worn for practical job tasks or in required areas.

- Management ensures the performance of up close and personal inspections of the PPE during some of those observations.

- Yes, employees should be coming to you with problems, but they won’t always. So, it would help if you verified the condition of the PPE.

- Any PPE found to be damaged or sufficiently soiled (high visibility apparel) will be removed from service, and the following will be done with it:

- It is suitably discarded and replaced.

- It is cleaned and repaired such that it is brought back to a usable condition.

PPE Limitations

At the beginning of this article, it was said that PPE is the first line of defense in protecting against workplace hazards, right? NO! That’s backward. PPE is the LAST line of defense against such hazards. That’s because PPE has limits. It isn’t meant to take the place of other safety controls. If you use heavy industrial equipment capable of cutting you to ribbons, it better has some engineered machine guards (or similar) to offer protection.

PPE isn’t as good as higher forms of protection because it requires the changing employee behavior to wear it. They must use PPE correctly every time they are exposed to a hazard. They have to use the right PPE. They have to clean and inspect it. They have to discard it and get it replaced when needed. And they have to do all of that while still trying to focus on everything their job requires. But, once you put up machine guards or substitute a harmful chemical for one that’s much less harmful, the work is generally done. Then, employees can do their work.

Lastly, PPE is easier to overwhelm with the hazard than the higher controls. You aren’t removing the hazard so much as offering something to help mitigate the hazard. There’s only so much air an SCBA can contain, only so much contaminant a filter can remove, and only so much durable PPE like gloves and hard hats can take. Don’t use PPE as a substitute for other controls. Use PPE for the residual hazards that remain after you’ve used the other controls.

Conclusion & Key Takeaways

In conclusion, PPE is an important part of workplace safety, but it should never replace higher hazard controls. Based on my experience, a thorough PPE hazard assessment is always necessary to determine the appropriate equipment for the job or area. Proper use, maintenance, and disposal of PPE is essential. When selecting PPE, a holistic approach should be taken, and interconnecting equipment that works together seamlessly should be chosen. The main types of PPE include eye and face protection, foot protection, hand protection, head protection, respiratory protection, and high-visibility clothing. By understanding and following these guidelines, we can help ensure the safety and well-being of all workers in the workplace.