ASTM f2413 11 Explained

There’s a wide variety of safety toe boots and shoes available now, and choosing among the options can be quite confusing. This task gets more challenging when faced with a host of safety enhancements built into each work boot, with each feature presented not through words but by using a series of letters and numbers. These symbols are usually printed on labels located on the boots or shoes’ tongues for increased visibility. Still, they won’t be very helpful if the wearer doesn’t understand them clearly.

What do the letters and numbers printed on safety work boots mean? In this article, we’ll focus on one of the most common numbers that can be encountered when choosing safety toe work boots, which is ASTM F2413-11. Discovering what these letters and numbers signify will help determine which protective features are built into the boots, enabling you to maximize the footwear you choose in the workplace.

ASTM F2413-11 – Definition

ASTM F2413-11 refers to the standard specification covering the minimum requirements (for performance, testing, design, and classification) and the specified criteria (for performance, function, and fit) of safety toe footwear. ASTM stands for ASTM International or formerly American Society for Testing and Materials – an international organization focused on developing and publishing voluntary technical standards for various systems, services, materials, and products – including safety footwear. ASTM F2413-11 specifically concentrates on the minimum standards for work footwear with safety toe caps, which aim to protect against hazards that can cause injuries in the workplace.

Understanding the ASTM Label

The ASTM specifications of safety toe work boots and shoes must be presented clearly, such as with a tag or label placed on the inner portion of the footwear’s tongue.

This label should have the performance requirements printed for easy visibility. An example of what this label looks like is given below, along with an explanation of each line (with the included numbers and letters).

ASTM F2413-11

F I/75 C/75

EH PR

Line 1 – “ASTM F2413” corresponds to the ASTM standards for safety toe footwear (works or boots with toe caps). Meanwhile, the number “11” after the dash signifies the year (in this case, the year 2011) when the standards were set in place or the year when they were last revised.

Line 2 – The letter “F” signifies that the footwear is designed for female use (M for males). “I/75” means that the toe cap delivers impact resistance of up to 75 pounds, and “C/75” pertains to the toe cap’s ability to resist compression up to 2,500 pounds.

Line 3 – This line includes any other protective qualities that the footwear offers. In the example, “EH” refers to an electrical hazard-safe design, while “PR” signifies that the boots or shoes have puncture-resistant soles.

ASTM Performance Requirements

Safety toe work shoes and boots that conform to the ASTM F2413-11 specification meet the specified performance requirements for these safety standards:

Impact Resistance (I)

This standard is focused on the toe cap’s ability to protect against different levels of impact. The ASTM F2413-11 still has the “75” to signify that the toe cap offers protection against impact coming from a 75-pound force.

It’s worth noting that more recent updates (such as the ones in ASTM F2413-18) now require safety toe work boots or shoes to have the highest level of impact protection, so the numbers aren’t included anymore. This means that “I” corresponds to toe caps need that will protect the toes against being crushed by sudden impacts from a force that can reach up to a maximum of 75 pounds.

Compression Resistance (C)

Compression-resistant toe caps protect the toe area against serious injuries that can come from compression coming from up to 2,500 pounds of force. Compared to the force that’s referred to in impact resistance, compression corresponds to a more sustained force that’s associated with a rolling object – such as a truck’s wheels rolling over the boot.

Like with impact resistance, the presentation of compression resistance in ASTM labels has changed with more recent updates after ASTM F2413-11 (such as those applied by ASTM F2413-18). Instead of using a letter followed by numbers, compression resistance is now presented simply as “C”, meaning the footwear has been tested to provide the highest level of protection for compression.

Metatarsal Protection (Mt)

Metatarsal protection refers to the safety work boot’s protective enhancements to keep the metatarsal bones (located at the top of the foot) safe from injuries that may arise from exposure to dangerous impact or compression. Metatarsal guards are built into the boots, forming a shield over the top part of the foot that’s not covered by the safety toe caps. These protective enhancements can be placed internally (such as the one that’s fitted into the Georgia Boot Hammer Internal Metatarsal Guard Steel Toe Boot) for a more discreet way of protection or externally (like the one on the Iron Age Groundbreaker External Met Guard Boot) to protect a larger surface area.

Conductive Properties (CD)

Safety footwear with conductive properties dissipates static electricity from the body to the ground. This reduces static electricity and the risk of sparks, significantly minimizing the risk of sparks that may lead to ignition or explosion, especially when working around volatile or explosive substances.

Electric Hazard Resistance (EH)

Safety work boots with electrical hazard resistance offer secondary protection against electric shock, meaning other protective measures need to be put in place to protect workers in environments with electrical hazards. EH safety boots – such as the Carhartt Rugged Flex 6-Inch Comp Toe Work Boot – and shoes are constructed with outsoles and heels that protect against electrocution in case of accidental contact with live wires or other electrically charged objects in dry conditions.

It’s worth noting that the electrical hazard resistance of safety footwear can be significantly compromised in wet weather conditions, or if the sole is penetrated by conductive materials, including nails or metal shavings.

Static Dissipating (SD)

Static dissipative safety shoes and boots minimize the accumulation of excess static electricity with the conduction of static charge from the body to the ground. At the same time, the footwear provides a high level of resistance for enhanced safety, especially in job environments where static electricity is generated by various processes that are continuously at work. It should be mentioned that static dissipative footwear conducts electricity, so it shouldn’t be used in conditions where there’s a risk of exposure to electrical hazards.

Puncture Resistance (PR)

Puncture resistance refers to the safety footwear’s capability of blocking puncture hazards from penetrating from the bottom. The puncture-resistant plate is fitted into the midsole (between the outsole and insole), forming a protective barrier that stops sharp objects (such as nails or pieces of glass) from penetrating. The protective plate can be made of steel or nonmetallic materials, such as Kevlar. Puncture-resistant safety shoes and boots (such as the Caterpillar Parker Steel Toe Work Boot) protect the feet against serious puncture injuries in work conditions where sharp objects can accidentally be stepped on.

It’s important to note that safety boots and shoes with the ASTM F2413-11 designation of “PR” have puncture-resistant soles – but this level of protection doesn’t necessarily apply to other parts of the footwear (unless specified). If this safety feature is needed in the top components of the footwear, it’s best to look for work boots with puncture-resistant uppers for maximum protection.

Top-notch Work Boots with ASTM F2413-11

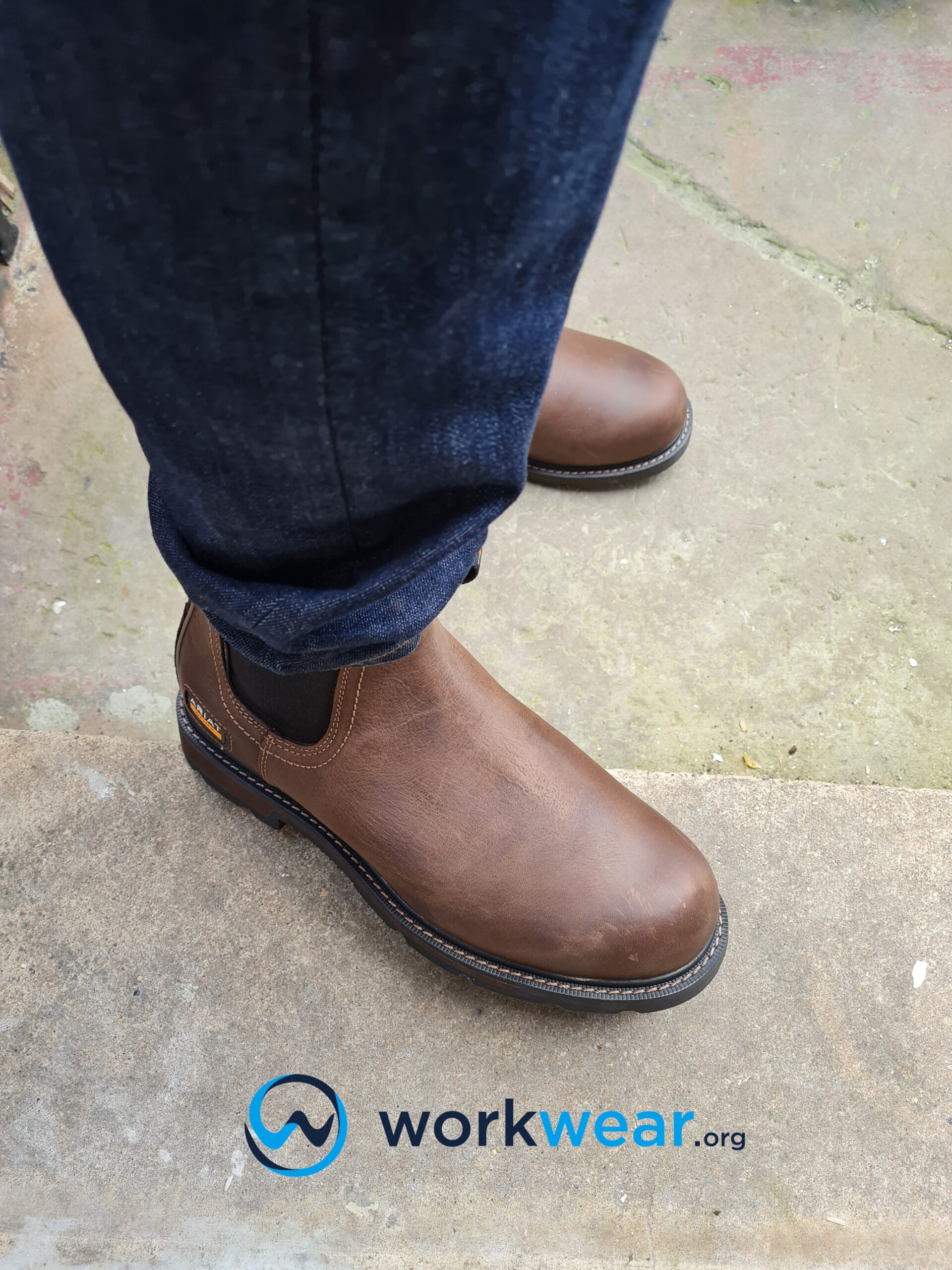

Ariat Groundbreaker

This leather work boot features the exclusive Waterproof PRO construction that seals out liquids, ensuring that the interior maintains continuous dryness even with exposure to mud, water, and other sources of wetness in the environment. It’s rated ASTM F2413-11 M I/75 C/75 EH, with a steel toe cap that provides superior protection against impact and compression hazards that may suddenly drop or roll from elevated areas. The electrical hazard-safe design offers a secondary source of safety from electrocution in case of unintentional exposure to open circuits in dry conditions. The reflective piping makes the boot more visible in the dark, while the 90-degree heel and slip-resistant Duratread outsole help maintain stability over challenging surfaces. Read full review.

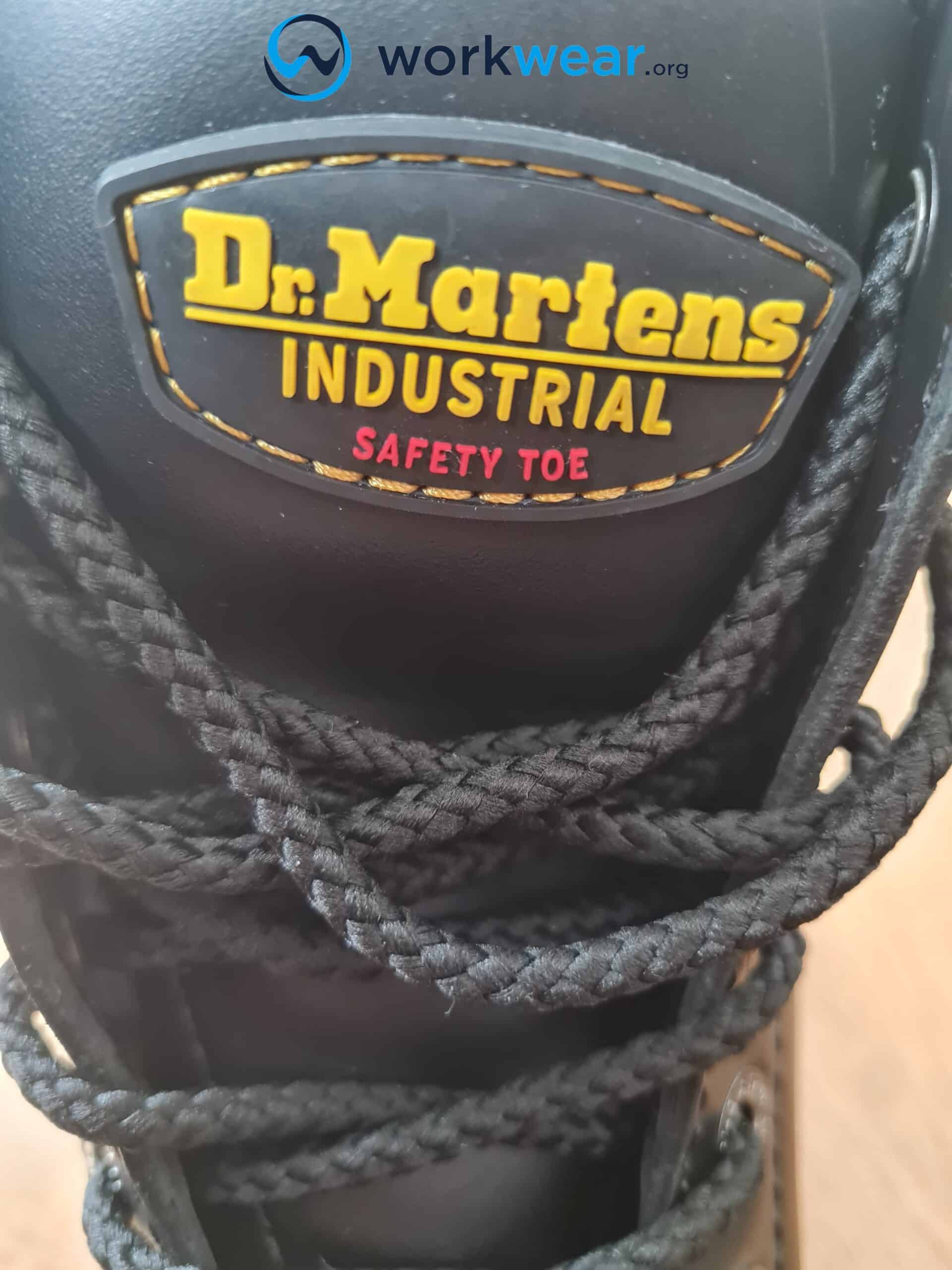

Dr Martens Icon 7B10 Steel Toe Work Boot

This ASTM F2413-11 M I/75 C/75 EH-rated work boot protects against electrical hazards, acting as a non-primary layer of protection to prevent shock when there’s accidental contact with electrically charged components in dry conditions. The steel toe cap shields the toes against severe injuries that may be caused by dangerous compression and impact in the workplace. A moisture-wicking lining helps keep the interior dry and cool for longer, preventing a hot and sweaty feeling from building up after long hours of continuous boot use. Meanwhile, the slip-resistant outsole offers a firm grip on various ground conditions to make it easier to avoid slipping accidents. Read full review.

Conclusion

Sorting through the vast array of work boot choices will be much easier when you’re armed with the necessary information. Understanding the most common enhancements in safety work boots is a great start, enabling you to fully appreciate the qualities that differentiate one option from the other. In addition, becoming familiar with the safety specifications – such as those that are presented in ASTM F2413-11 labels – can help narrow down your choices among a wide range of options. The knowledge will also help you choose the safety work boots that match the detailed requirements of specific jobs and work settings, delivering maximum safety exactly where it’s most needed.

FAQs

- Is it possible to find soft-toe work boots with the ASTM F2413-11 certification?

- No – the ASTM F2413-11 certification is specified only for work boots and shoes that have protective toe caps. The first requirements that need to be met with this certification involve compression and impact resistance, which are delivered only by the toe caps that are permanently built into safety toe work boots.

- What’s the difference between ASTM F2413-11 and ASTM F2413-18?

- The 2018 update requires the markings specifying the safety features/performance requirements to be enclosed in a rectangular border. There are also some changes in the way the information is presented – with Line 2 now including metatarsal protection (where applicable) along with the gender, impact resistance, and compression resistance information. Aside from having a Line 3, the ASTM F2413-18 update may also include a Line 4 – with these last two lines used for presenting the other types of safety specifications/features.

- Do puncture-resistant boots protect the feet from puncture hazards from all angles?

- No – in this case, the puncture resistance is concentrated on the sole area. This means that the bottom of the work boots won’t be pierced by objects that are stepped on. However, the footwear won’t necessarily protect against sharp objects that touch the boots or shoes from the top or the sides unless this safety enhancement is clearly specified.

- Do all jobs require ASTM F2413-11-certified boots?

- No – there are jobs that don’t their workers to have this safety certification in their footwear, and these are the professions that don’t have exposure to harsh environments. As the work surroundings aren’t exposed to safety threats- such as compression, impact, puncture, or electric shock hazards – work boots that have protective features against these hazards aren’t required.