Anatomy of Work Shoes – Terminology and Key Parts You Need to Know

Aside from price, materials used and the option for safety toes are the main aspects that people tend to focus on when choosing work shoes. It’s natural to concentrate on these points to sift through the wide variety of products to choose from. But did you know that it also pays to know more about the parts that make up the structures of work shoes? By doing so, you can have a more in-depth way of choosing through the numerous products available and selecting the pair that will be most beneficial for your needs.

Becoming familiar with the key parts of work shoes will also give you a better appreciation of how these components work together, making the footwear perform its best on the job site.

Key Takeaways

- The terms used for the parts of work shoes can be a bit confusing. Knowing these terminologies is a good idea because they can help you discover how each part plays a key role in the performance of work shoes.

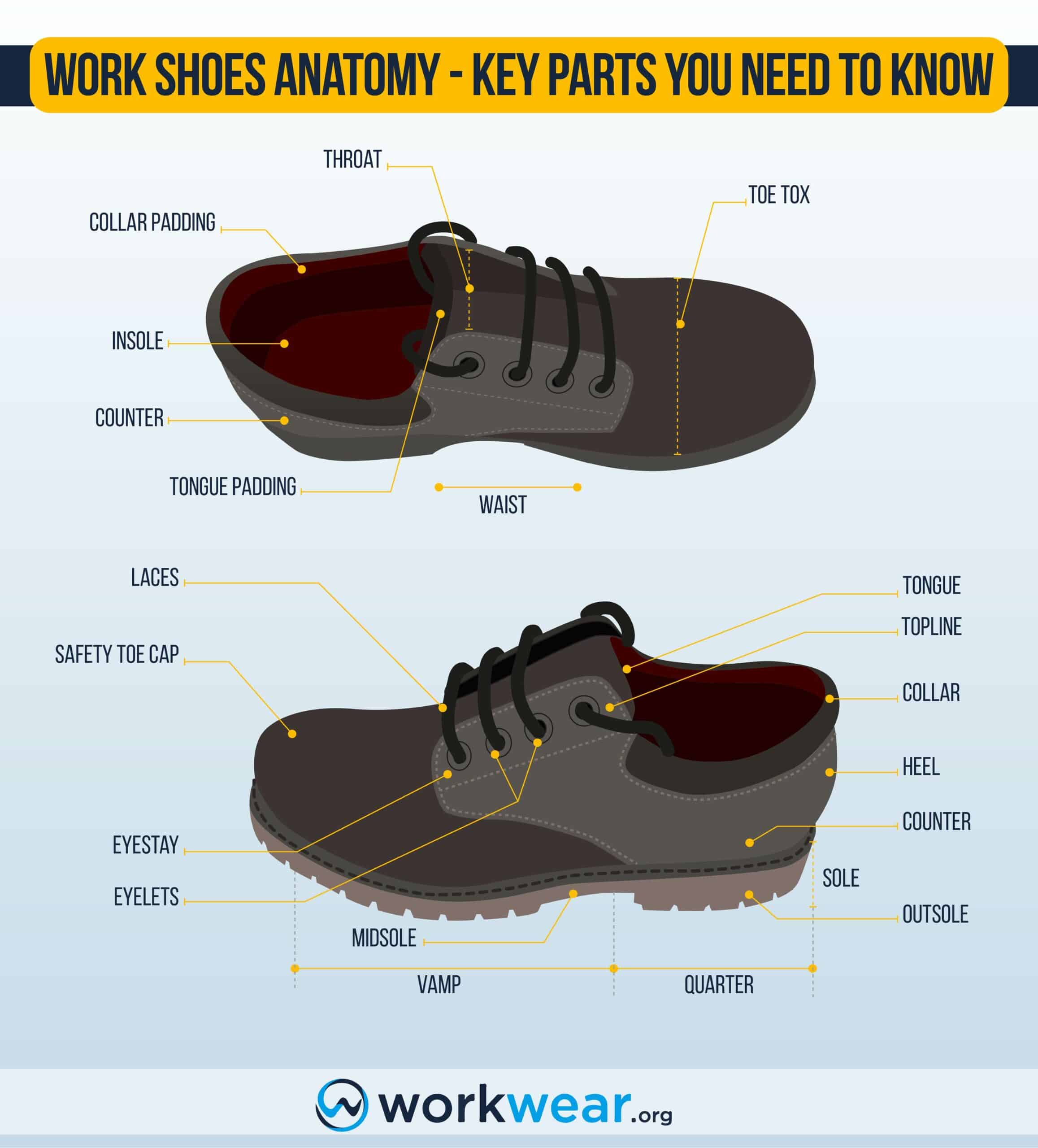

- The upper comprises key parts: toe box, safety toe caps, laces, eyelets, eyestay, tongue, tongue padding, topline, throat, collar, collar padding, counter, vamp, and quarter.

- Meanwhile, the bottom portion of the sole has these main parts: insole, waist, midsole, sole, heel, and outsole.

- These components work together, enabling work shoes to deliver the reliable support, comfort, protection, and stability needed to perform well in various job environments.

Terminology the Most Important Parts of Work Shoes

Key Parts of the Upper

Toe Box

The toe box is the part at the front end of the shoe that covers the toes. In work shoes, this component can be enhanced with metal or nonmetallic toe caps, providing increased toe protection against impact and compression hazards that may be encountered on hazardous job sites.

Even without safety toe caps fitted in, the toe box is usually reinforced with a sturdy material that maintains good aesthetics on the tip of the shoe and offers more protection against impact and abrasion.

Safety Toe Cap

A safety toe cap is fitted inside the toe box to reinforce the area.

It protects the toes against serious injuries when heavy objects – such as tools and construction materials – accidentally drop onto the work shoes.

Safety toe caps can be made from metallic or metallic materials. Steel toe caps provide maximum protection against dangerous impact and compression.

These metallic safety toes make work shoes heavy.

On the other hand, composite toe caps also offer great toe protection without excessive weight and tend to be more comfortable for long hours of use.

Laces

Laces hold the work shoe’s top part (or the throat) closed. The shoelaces are designed to be threaded through the eyelets and pulled until a secure; comfortable fit is achieved. Aside from being functional parts, laces can also play key roles in the work shoes’ appearance. For example, they can give the shoes a seamless look or, in the case of sporty work shoes, may even add a contrasting color for a more interesting profile.

Eyelets

The eyelets are the small holes where the laces go through. They are attached to the eyestay, with both components working together to keep the laces properly. The eyelets can be formed by forming slits or holes onto the eyestay, but some are reinforced with metal or hard plastic rings, making them a lot more durable to keep up with numerous lace fit adjustments.

Eyestay

Also called a lace stay, this is the part that supports the laces in place. The eyestays are fitted into each shoe side, where the eyelets are attached to keep the laces in place. This component may be made with the same material as the rest of the upper (such as leather) for a seamless look. However, there are work shoes – such as those with sporty designs – that feature eyestays made with different materials for better function while also working to accent the overall look.

Tongue

The tongue is positioned on top of the foot to prevent the laces from rubbing directly against the skin, which can lead to discomfort. This component is also responsible for stopping small stones and debris from getting into the shoe. The tongue usually sits below the laces, but sometimes a flap is added where the laces can be threaded through, keeping the laces more securely positioned.

Tongue Padding

The tongue padding refers to the softer parts portions of the tongue – mostly on the end that directly touches the top of the foot, although some tongues can be entirely padded. This cushioned section offers a more comfortable experience as it protects the skin from rubbing against a stiff or abrasive material.

Topline

The top line can be seen at the top portion of the upper, right above the collar. It can showcase visible stitching that holds the components together while also adding a nice contrast to the work shoe’s other materials.

Throat

The throat is the section of the work shoe where the tongue is attached. This opening is usually surrounded by the eyestay and is covered on top by the laces. The throat can be opened all the way (open lacing) when the entire tongue can be pulled out, such as in work shoes with a Blucher style. It can also feature a closed lacing system (Balmoral style), where the upper is divided into two sections, and only the top part of the tongue can be pulled out.

Collar

The collar refers to the part surrounding the work shoe opening and where the foot is inserted.

Depending on the work shoe’s style, the collar can be cushioned to provide better comfort. It can also be unlined in leather work shoes with dressy styles that have more streamlined silhouettes.

Collar Padding

The collar padding adds the required cushioning to the opening of the work shoes, making this section more welcoming and comfortable. In addition, it protects the ankle from rubbing painfully against the collar and can also contribute to a more secure it in this area.

Counter

The counter (or heel counter) refers to the part at the back of the work shoe that surrounds the heel bone. It’s usually reinforced with rubber, TPU, or other strong materials and is often much harder than the other sections of the upper.

This extra rigidity is needed to keep the foot stable, so it’s easier to walk without losing your secure footing. The heel counter also maintains the shoe’s original shape at the back.

It’s worth noting that if the work shoes don’t fit properly, the heel counter can cause discomfort when it starts rubbing on the heel area.

Vamp

The vamp refers to the front section of the shoe. It covers the area from the tip of the toe down to the rear quarter, right before the shoe forms the heel part. Only one material (such as leather) can be used for the vamp and quarter, although some work shoes use different materials for these two sections.

Quarter

The quarter comprises the back part of the work shoe’s upper. It usually starts from the end of the vamp (extending from the tip of the shoe to almost the heel) and also encompasses the heel area. But, again, the work shoe’s style will dictate whether the quarter is made of the same material as the vamp or if these two sections are made of different materials.

Key Parts of the Sole

Insole

Located inside the shoe, the insole is on top of the midsole and is in direct contact with the bottom of the foot.

It acts as a supportive base, often with enough cushioning to keep the foot comfortable while walking or standing.

Insoles can have more feature enhancements that deliver improved performance and comfort, such as arch support, odor control, and antibacterial and moisture-wicking capabilities.

Insoles are sometimes referred to as footbeds. They can be detached, so it’s easier to get the customized fit and personalized level of cushioning or support you need by just replacing the insoles with the ones you prefer. However, there are also permanently attached insoles, in which case thinner inserts can be placed on top for improved performance.

Waist

The term waste is used to describe the narrowest portion of the work shoe’s sole. Like in the human body, this shoe part dips to form a curve from the wider areas. It corresponds to the spot directly under the arch of the foot that’s found between the ball and heel portions. In general, shoes with narrower waist areas offer stronger arch support.

Midsole

The midsole is fitted into the area between the insole and outsole.

It adds much-needed support for the foot to maintain a comfortable feel while walking or standing, especially for long periods. At the same time, the midsole takes on the role of the shock absorber as it soaks up the impact coming from continuous steps on the hard ground.

The midsole then distributes the force to prevent foot fatigue issues.

In some safety work shoes, the midsole is reinforced with a puncture-resistant plate that stops sharp objects from piercing from the bottom. The plate can be made from metallic materials, such as steel, or nonmetallic components (such as Kevlar). It protects the foot against serious puncture injuries if you accidentally step on sharp objects left lying on the ground.

Sole

The sole is a collective term for the parts of work shoes located at the bottom – the ones that support the foot. Sometimes the sole can refer to the midsole, outsole, and heel portions, although these components have distinct structures and functions.

Heel

The term “heel” can refer to the portion at the back of the work shoe that sits directly against the heel bone. This portion is connected to and works with the heel counter to keep the foot supported and stable. The term can also refer to the part attached to the sole, raising the shoe for added height and supporting the foot from the bottom. In addition, heels can aid in stabilizing the work shoes, especially when used in inclined or unstable ground conditions.

Outsole

The outsole is the outermost portion of the work shoe at the bottom and the one that touches the ground. It can be made from different materials, including rubber (which may be the most common for work shoes and boots), TPU, leather, and some unique combination of materials exclusive to certain brands.

The outsole plays a key role in the level of traction that the work shoe offers.

The material and structure of the outsole can dictate how grippy the footwear will feel while walking on different surface conditions. For example, a higher level of traction or grip can make it much safer to navigate wet or slippery ground, resulting in improved safety in the workplace.

Some outsoles also offer enhanced features, including insulation from heat and cold and strong abrasion resistance.

Conclusion

When choosing work footwear, it’s a great idea to have more information other than the material and size of the pair you’re eyeing. Knowing the parts that make up a pair of high-quality work shoes can help you appreciate how each component contributes to superior performance and comfort. For example, the upper is composed of the following key parts – toe box, safety toe caps, laces, eyelets, eyestay, tongue, tongue padding, topline, throat, collar, collar padding, counter, vamp, and quarter. These components all work together to maintain exceptional function, aesthetics, and protection for the foot. Meanwhile, the sole or bottom portion of the work shoe consists of the insole, waist, midsole, sole, heel, and outsole – which all deliver continuous comfort, support, and stability to keep you moving almost effortlessly in varying ground conditions.

FAQs

- Do all work shoes need laces?

- No, there are work shoes that work well, even with lace-free styles. However, the shoes with lace-up designs offer better stability and support since the laces enable their fits to be easily customized.

- Are work shoes with detachable insoles more comfortable than those with permanently attached insoles?

- Not necessarily. Work shoes with permanently attached insoles feel comfortable even out of the box. The removable insoles make it easier to personalize the shoes’ fit.

- How can a cushioned collar improve stability?

- The padding makes the collar a bit bulkier, so it can form a tighter embrace on the ankle. This helps keep the ankle stable and prevents unwanted movement or twisting.

- Aside from added height and stability, how else can raise heels on work shoes help you?

- Work shoes with raised heels offer increased clearance between the ground and the bottom of your feet. This quality is very helpful in keeping your feet dry and protected while walking on wet or cold surfaces.