Replacing vs Resoling Work Boots

It’s hard to let things go, especially if you’ve come to love that item and enjoyed its benefits for a long time. This applies to a lot of things, including footwear. Work boots are designed to last through extended periods of use even in challenging conditions, but, like other things, they also have a breaking point.

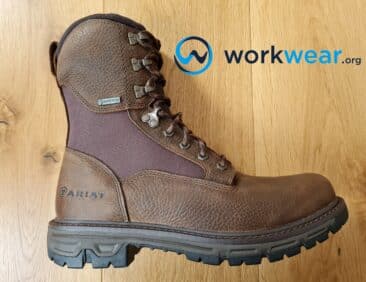

When the boots start to show signs of damage, it’s time to start looking for a new pair that can give the same benefits on and off the job site. However, if the damage is mainly on the sole, there may be a possibility that the boots can be given a new lease on life with a resoling process.

The construction method will also dictate if the boots can be re-soled or not. Deciding on whether to buy a new pair of work boots or get them re-soled can be quite difficult, especially if you don’t know what each option involves. In this article, we’ll discuss the pros and cons of each alternative, making it easier for you to choose the option that’s not only appropriate to your work boots’ condition but will also bring the greatest benefits.

Key Takeaways

- Work boots are built to withstand heavy use in varying conditions but obvious signs of damage, especially on the sole, need to be resolved to ensure continued safety and comfort in the work area.

- Replacing old work boots will enable you to enjoy a new style with brand-new materials and the upgraded features that you need. Both the sole and upper are in top form, and the safety features haven’t been compromised yet with constant use and abuse.

- However, you’ll have to go through a new break-in period with new work boots, which are also generally costlier than resoling.

- Resoling work boots maintains the customized fit and prolongs the life of high-quality uppers, especially the ones that are stitched onto the soles. The process costs less than buying new work boots and is environmentally friendly as well.

- It should be noted that resoling can damage the boots if done incorrectly. The resoling process can take a long time and is not recommended for low-quality uppers that may not last long.

Replacing Work Boots

The easiest way to deal with worn-out work boots is to just replace them with a new pair.

The new boots will offer a fresh start that doesn’t come with the potential problems of used footwear.

If the replacement pair you’re considering is readily available, you can immediately reap the benefits of new footwear without the long wait. Also, replacing the damaged work boots may be the only possibility available if the boots’ soles are cemented or glued to the upper. This is because resoling is generally only suitable if the soles are stitched to the uppers, such as with boots that are constructed using Blake Stitch, Goodyear Welt, and Stitch-down methods.

Key Advantages of Replacing Work Boots

All parts and materials are brand new

You’ll be able to enjoy wearing brand-new work boots if you decide on replacing your old pair. You’ll get that distinct satisfaction of wearing a new product that won’t come with using your old boots, even if you just have them re-soled.

The components and materials are in excellent form because they haven’t been used yet.

Think of the brand-new pair as a well-deserved treat for all your hard work, as well as an investment in your comfort and safety while in the workplace.

You get to enjoy a different style

Replacing your old work boots with a new pair gives you the chance to try a different style, although you may also lean towards buying the exact same style as the worn-out pair if you already loved that product. Even if work boots are mainly chosen for their performance and benefits while on the job, there’s nothing wrong with choosing a product that also looks great and can be partnered with various outfits in and out of the work area.

Chance to upgrade the boots

When you buy a new pair of work boots, you get a chance to go for the ones with upgraded features.

If you currently have a water-resistant pair, maybe you want to buy a choose a new one that’s completely waterproof. For cold-weather use, you might want to upgrade your regular work boots and go for insulated ones that also have a stronger grip on slippery surfaces. Saying goodbye to your old work boots is a chance to enjoy new work boots with enhanced features that can increase your comfort and efficiency in the workplace.

The sole and upper are both in excellent shape

Getting a new pair of work boots gives you the guarantee that both the upper and sole are still in top form.

The same can’t be said for re-soled boots since their uppers are older than the soles. Even if the uppers are made with premium quality materials, they may not be in their best form if they’ve already been used for several years, especially in tough work environments. With brand-new boots, you’ll have the chance to enjoy uncompromised quality, comfort, and protection that can only be delivered with non-worn-out or non-damaged materials.

Uncompromised safety features

Brand-new work boots still have all the safety features working together the way they’re designed, providing the highest level of protection against specific threats that can be encountered in the work area. The materials and components are in top form, so the work boots’ protective qualities as just as intact and offer a level of protection that hasn’t been compromised yet by normal wear and tear.

Key Disadvantages of Replacing Work Boots

Will need a break-in period

Most work boots need a break-in period before they can become truly comfortable to wear throughout the day.

When you buy a new pair, you would need to allot a breaking-in phase again to make the boots soft enough, so they won’t feel uncomfortably stiff when you walk. This means that you’ll most likely need to go through a bit of discomfort for some time again, the same way you did with your old pair before the work boots can be flexible and soft enough to feel completely comfortable.

Generally, more expensive than resoling

Buying a new pair of work boots generally costs higher than having your old pair re-soled.

The expense will be even higher if you’re looking for an upgrade from your old pair and are after boots that come with even more features. Resoling extends the life of old work boots, especially if the uppers are still in good condition and are expected to last for a bit longer.

Resoling Work Boots

Resoling makes it possible for you to continue enjoying the same pair of boots that you’ve been relying on while on the job. This method is ideal for work boots with uppers made of premium materials because they’re expected to keep up with the new soles to which they’ll be attached. Resoling is also suitable for boots that are constructed by stitching the uppers to the soles – such as work boots that are built using the Blake Stitch or Goodyear Welt methods.

Key Advantages of Resoling Work Boots

More affordable than buying a new pair

Resoling old work boots costs significantly lower compared to buying a new pair.

This is because you’re only paying for the new sole component and the resoling service (plus the shipping fees if applicable), which is much lower than the cost of brand-new materials for both the soles and uppers. In some cases, resoling can be a bit more expensive (such as for logger boots or high-heeled boots that will need more work). However, in general, resoling is still considered more cost-efficient than buying a new pair of work boots.

Maintains the personalized comfort of old boots

When you have your work boots re-soled, you preserve the customized feel that you’ve developed over years of continuous use.

That personalized level of comfort that was achieved as the material molds to the shape of your foot can still be enjoyed when you want to extend the life of your boots with resoling. This is because the uppers and footbed – which have contoured to the shape of your foot – are left intact since the outsole is the only portion that needs to be removed and replaced during the resoling process.

Extends the life of high-quality work boots

Resoling is a fantastic way of extending the life of premium-quality work boots. These products typically have uppers that are designed last for a long time, performing and looking remarkably well even if their soles already have visible signs of damage.

The uppers on high-quality work boots can often last through two to three resoling procedures, making it possible for you to continue experiencing the superior features while solving the issue of worn outsoles.

Environmentally friendly

Resoling work boots offers a more sustainable option to purchasing a new pair.

When you extend the life of your work boots by having them re-soled, you don’t add to the waste problem since you don’t automatically throw away the boots and buy a new pair. This way, you do your share of helping the environment as the boots won’t be added to landfills and instead can still be used for much longer when they’re re-soled

Great option for work boots with premium quality uppers

Top-quality work boots with premium materials and construction will benefit from resoling, especially if their soles are stitched to the uppers. This is often applicable to boots with handcrafted designs as well as to those that are made with the finest materials and stitching methods, resulting in structures that are built to last much longer than the average work boot.

By replacing the damaged soles, the premium quality uppers can still offer more years of reliable comfort, protection, and support. Work boot brands such as Danner and Thorogood offer their own resoling services to extend the use of their high-quality work footwear.

Key Disadvantages of Resoling Work Boots

Non-professional resoling can damage the boots

If the resoling process is done by someone without the proper experience and tools, the work boots can end up getting damaged.

This is such a shame, especially if the high-quality materials are compromised as well and can’t be used anymore after the botched attempt at resoling. Some people may even try to remove the outsole in the hopes of doing a cheaper, DIY resoling – this should also be avoided if you want to avoid ruining the boots.

Resoling can take a long time

The resoling process can take a long time.

This is true if you personally take the boots to a cobbler, and even if you have the work boots shipped to be re-soled, which can take a few weeks to be finished – although replacing just the heels of your boots can be usually completed in one day. This may require you to use a spare pair of work boots, which may not be as comfortable as the ones you sent for resoling which already have a personalized fit.

Not suitable for low-quality boots/uppers

Resoling isn’t worth the effort for boots with uppers that won’t last that long anyway.

The process isn’t recommended for lower-quality uppers that may be showing extensive signs of damage by the time the resoling process is considered. If both the uppers and soles look like they’re about to fall apart, it’s best to just buy a brand-new pair of work boots.

Replacing vs Resoling Work Boots – Comparison Table

| Boot Type |

Pros |

Cons |

|---|---|---|

| Replacing Work Boots |

|

|

| Resoling Work Boots |

|

|

Conclusion

When work boots start to show obvious signs of damage, especially on the soles, it’s important to address the issue to ensure continued performance and safety benefits. You have the option to replace the old boots by buying a new pair, or (if applicable) have them re-soled professionally. When you purchase new work boots, all the materials are brand new, with the sole and upper still in their top forms. The brand-new pair showcases safety features that haven’t been compromised by normal wear and tear, plus buying new boots gives you a chance to try on a new work boot style. However, new boots will require a break-in period, and they’re generally more expensive than re-soled footwear. Meanwhile, resoling work boots is the more affordable option that significantly prolongs the life of premium-quality uppers, especially those with handcrafted styles with the soles stitched on. Re-soled work boots are more sustainable and maintain a comfortably customized fit even after the new soles are attached. It’s worth noting that resoling that’s done incorrectly can damage the boots, though, and the process can take a long time and is unsuitable for lower-quality uppers that won’t last very long anyway.

FAQs

- Is there a minimum or maximum length of use for work boots before they can be re-soled?

- No, there are no specified time frames to be followed before boots can be re-soled. When the sole starts showing signs of damage – such as separating from the upper or water seeping in – it’s time to consider resoling if it’s suitable for the boot’s construction.

- How many times can work boots be re-soled?

- Typically, high-quality work boots can be re-soled two to three times, but this can vary depending on footwear usage and how long the uppers will resist damage.

- Why do worn-out treads indicate that it’s time to replace the sole or buy a new pair of work boots?

- Worn-out treads not only have a negative effect on appearance, but they also pose safety issues. If the treads have almost entirely worn away, the work boots are unable to grip the ground strongly. This can result in slipping in unstable or wet conditions.

- Why are cheaper work boots unsuitable for resoling?

- The cost of resoling lower-priced work boots may exceed the cost of replacing them, in which case the resoling process doesn’t make sense. Also, replacement soles may be challenging to find for lower-quality work boots.