Zippers: Types, Uses, Sizes, And Everything In Between

Zippers are one of the most useful and essential components in clothing and work wear. From work pants to insulated jackets, zippers are essential. This article explores their history, types and parts, and sizes.

History of Zippers

The zipper has a long history and was invented by multiple people in sequential processes. However, none of these inventors made the general public accept zippers as an object of everyday use; it was the fashion and magazine industry that did this job.

When Elias Howe, the sewing machine inventor, received a patent for an “Automatic, Continuous Clothing Closure” in 1851, he focused on promoting his invention and did not give the patent a second thought.

Forty years later, Whitcomb Judson marketed his “Clasp Locker” invention by building upon Howe’s idea. He started the Universal Fastener Company to produce his innovation, initially meant as a shoe fastener. However, the product could have amassed more fame or attention on its debut at the 1893 World’s Fair in Chicago.

Eventually, Gideon Sundback – who worked at the New Jersey branch of the Universal Fastener Company – invented the modern zipper in 1913. He received a patent for his innovation in 1917 and marketed it as a “Separable Fastener.”

However, Sundback did not come up with the name “zipper.” The B.F. Goodrich Company first used this term and used Sundaback’s invention on a new rubber boot type. They named the device “zipper,” and it became a part of the consumer lexicon.

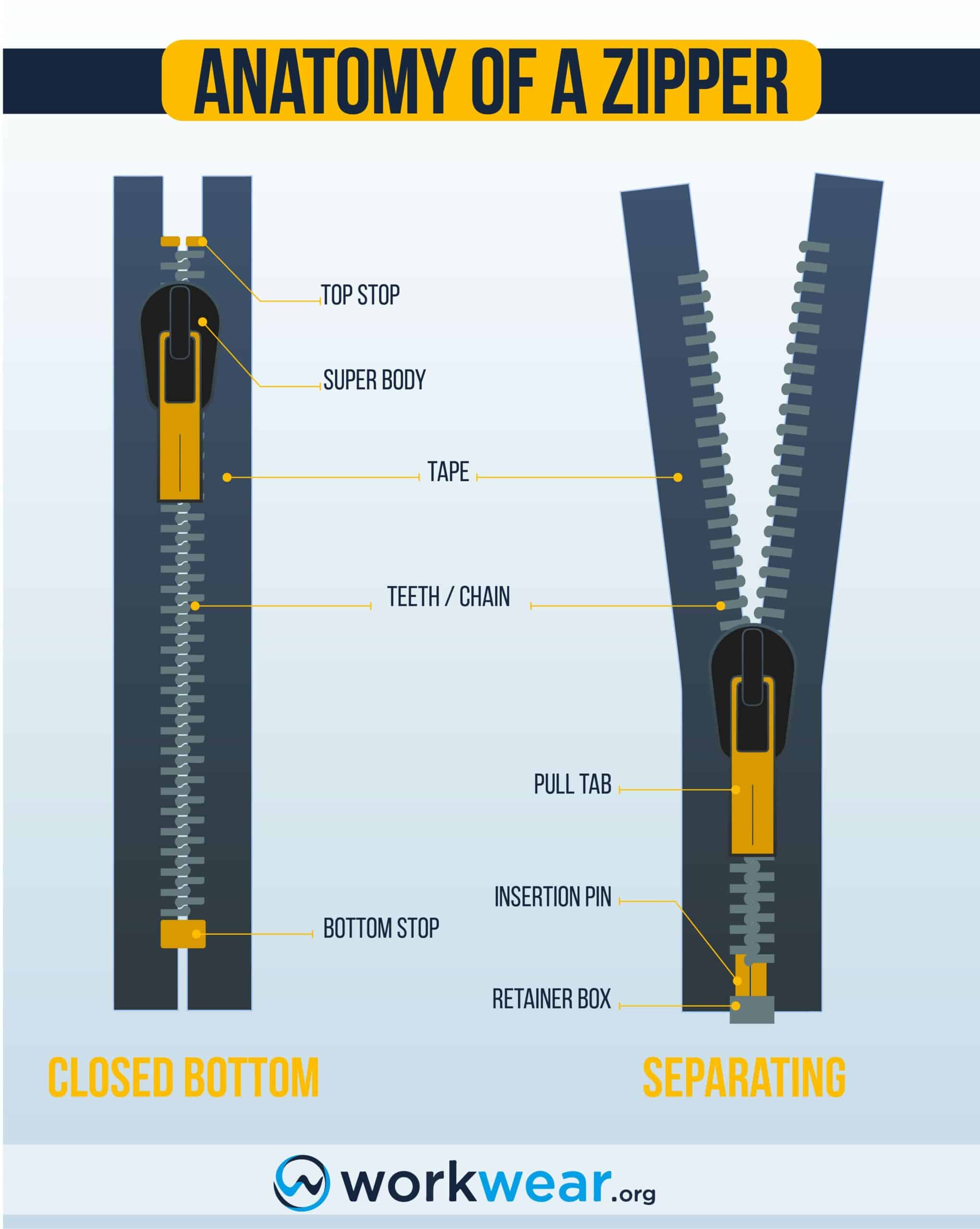

The Anatomy of a Zipper

Classes of Zippers

Delving into the anatomy of a zipper calls for a prior understanding of the two primary zipper classes: closed bottom and separating.

Closed Bottom

Closed bottom zippers have a specialized bar that moves across both sides of the zipper’s base, also known as the bottom stop, and helps hold the zipper in one piece.

Separating

As the name hints, separating zippers that split into two portions are commonly found on hoodies, jackets, and other similar apparel.

Parts of a Zipper

Top Stop

The top stop prevents a zipper’s slider from coming off its top end.

Slider Body

The slider body separates and joins a zipper’s teeth by sliding up and down its length.

Pull Tab

The pull tab is the piece you tug at to move the slider body up and down a zipper’s teeth.

Chain/Teeth

The teeth or chain in a zipper hold its two parts firmly together.

Tape

Tape refers to the fabric with which the zipper’s chain or teeth are attached.

Bottom Stop

The bottom stop prevents the slider from sliding off the zipper’s bottom. Therefore, it is used only in the case of closed-bottom zippers.

Insertion Pin

The insertion pin secures the two opposing zipper sides in the Retainer Box. It is only used in separating zippers.

Retainer Box

The retainer box keeps the zipper in place and prevents the slider from sliding off the bottom. It is only used in separating zippers.

Types of Zippers

All zippers may look the same to you but they come in multiple types. So let us take a look at a few of them.

Closed-End Zippers

Closed-end zippers are unequivocally one of the most common zipper types. These zippers are closed at the bottom end and do not allow the two zipper prongs to separate. In addition, they have a specialized stop at the end to prevent the moving slider from sliding off. The slider also prevents you from reattaching the teeth. Closed-end zippers are most commonly used on bags.

Separating Zippers

Separating zippers, also known as open-end zippers, offer ease and convenience by allowing the two prongs of a zipper’s teeth to separate. They contain a pin and box mechanism at their bottom end that fixes into the slider and helps attach or detach. Open-end zippers are generally used in jackets, coats, and other apparel.

Two-Way Separating Zippers

A two-way separating zipper has two slides on the same teeth, allowing you to tailor your opening’s placement.

Nylon Coil Zippers

Nylon coil zippers are one of the most typical zippers for materials. Made of plastic and polyester, nylon coil zippers are thin, small, lightweight, and look like metal. They are generally used on apparel and can be open-end or closed-end.

Nylon coil zippers also have different types based on usage, including the following:

Pant Zippers

Pant zippers, also known as fly zippers, are generally short, metal-like nylon zippers used in front of pants. However, they can also be used in blouses, purses, and pillows, as they have a stopper that prevents the chain from sliding off the end.

Bag Zippers

Metal-like, nylon bag zippers are longer than pant zippers – generally nine to 14 inches in length. They easily slide and do not lock, but the two teeth prongs do not separate at the lower end.

Metal Zippers

Metal zippers are sturdy and typically used for high-quality products such as high-end bags and heavy-duty gear. They are made from either aluminum or nickel and may be open or closed-end depending upon the product they are used on. However, metal zippers may rust because of dust or debris, so using vinegar is advisable to clean them between the teeth.

Moulded Plastic Zippers

Molded plastic zippers are the talk of the town nowadays, primarily because they come in various colors and sizes and are rust-resistant. Their teeth are tailored to come together seamlessly. Because they are relatively light in weight, they are used for jackets, bags, and other fashion designs.

Invisible Zippers

As the name hints, invisible zippers blend into the product; they are expertly sewn in and are not visible to the naked eye. They are generally used in apparel such as dresses, skirts, and for side seams. Invisible zippers are known for their narrow pull and are mostly hidden by a fabric strap.

Exposed Zippers

Exposed zippers are meant to be seen. Therefore, they are deliberately sewn on products in ways that expose them. Thus, if you see a molded plastic zipper’s colored plastic or metallic zipper on jeans, they have exposed zippers. Since their obvious appearance appeals to some people, designers expose zippers for stylistic objectives.

Water-Repellent Zippers

Water-repellent zippers are important for outdoor gear, including camping and marine equipment. These zippers are also rust-resistant and survive for a long in harsh conditions. In addition, they include air-tight seals and are so well secured that they are barely visible.

Lapped Zippers

Lapped zippers are rare and are used to hide zippers without rendering them invisible. Designers generally stitch them up through a specialized style to cover part of the zipper with fabric. They are used on backpacks and some other clothing applications.

Gold Zippers

Gold zippers are not made of gold but rather have an appearance that makes them look gold-plated. They are generally used on dresses, bags, or skirts to give them a formal and exquisite look.

Are Zippers Used In Work Wear?

Zippers are of everyday use in the workwear garment industry. They are widely used on work jackets, pants, pockets, dresses, and other formal wear. They are also used on some work boots, such as tactical boots that have side zippers.

Their extensive use in the formal wear industry makes them an indispensable tool for making apparel look comfortable, fitting, and appropriate for workplaces.

Zipper Size Chart

Zippers have multiple sizes mentioned on them next to a small # symbol. This number refers to the tooth size on a zipper, measured from the top outer edge to the bottom. The width between the two zipper edges, noted in millimeters, is the zipper size. Let us look at the following table to get wind of zipper sizes and what products they are good for, depending upon their general size.

| Zipper Number |

General Size |

Products They Can Be Used For |

|---|---|---|

| 1-4 |

|

|

| 5-7 |

|

|

| 8-10 |

|

|

Weight Considerations When Choosing A Zipper

It is essential to factor in the weight of the material and the overall product you are using a zipper on. Alternatively, you also need to keep in view the weight of the zippers when using them on garments. Some zippers, such as metal zippers, can be quite heavy. When used on fragile materials, they can cause the product to sag or eventually rip by constantly pulling it down. A metal zipper weighs approximately four times a nylon zipper, so consider it when choosing a suitable zipper.

Which Tools Do You Need To Work With Zippers?

Are you ready to work with zippers? Here are a few tools that you must have before starting!

Zipper Foot

A zipper foot is the one fundamental necessity for sewing with a zipper. Zipper feet come in two types:

- Invisible

- Regular

They must sew the zipper teeth close; a zipper would be useless without them. Invisible zipper feet are specially made for invisible zippers and are not used for other zipper types.

Make sure you steer clear of a universal foot when working with zippers. Universal feet can force the zipper teeth away from the needle, resulting in tears and rips.

Pliers for Shortening

Molded and coil plastic zippers can be conveniently cut with scissors if you need to shorten them. In contrast, metal zippers require you to remove and snip some teeth before trimming them. In addition, you will likely need pliers for shortening zippers when sewing, so it is advisable to keep them close by!

Invisible Tape

Although it may sound weird, invisible tape works wonders with zippers. You can tape the zippers down to prevent them from slipping and messing up your sewing.

Stabilizing Tape

Stabilizing tape, also known as wonder or stay tape, helps solidify a zipper onto a knit fabric. As a result, it prevents the fabric from unnecessary tears or stretching as you sew on it.

Zipper Care

Modern zippers come in handy in just about all products and all ways. They have replaced buttons due to their practicality. However, while they offer higher security, they are prone to breaking or malfunctioning. Therefore, it is essential to know how you can maintain your zippers.

Make sure to clean your metal zipper teeth with vinegar to remove all dirt and debris. Additionally, you don’t need to worry if you come across a broken zipper. Various convenient zipper fixing kits are readily available to help you fix your zipper chain, use alternative insertion pins, or attach a replacement slider.

Conclusion

Zippers are one of the most useful clothing components. They have multiple parts, come in different sizes and materials and provide convenience and flexibility.

FAQs

- Why do zippers split?

- Zippers are likely to split for two fundamental reasons: underuse and overuse. In both cases, the tension on the zipper’s slider loosens to a point where it fails to apply the pressure necessary to hold and pull the teeth in place.

- How do zippers work?

- Zippers work on a slider body that separates and pulls the zipper teeth together. The teeth are sized and shaped to allow the acting forces to hold. Thus, wearing the garment does not unlock or open the teeth.

- Can zippers be cut?

- Yes, metal zippers can be cut by removing the metal teeth, allowing you to remove the extra length before sewing in the garment. Tailoring your zipper length stops you from breaking needles when sewing it on a garment.

- Are zippers on different sides?

- The placement of zippers solely depends upon the designer. Although the unspoken rule is that both the zipper and the buttons on a garment are on the same side, the decision is generally left to the designer’s preference.

- Do zippers shrink?

- Zipper shrinkage or arching is relatively common and affects zippers when the garment they are attached to is steam ironed.

- Who invented zippers?

- Gideon Sundback invented the modern zipper in 1913.