Main Factors and Features that Ascertain Durability in Work Footwear (Based on our testing experience)

Choosing the right footwear is crucial to ensure that your feet stay safe and comfortable as you work. It’s natural to focus on the safety features that are fitted in, but it’s equally important to look at the overall durability of the footwear.

Durable work boots and shoes will perform well for longer periods, protecting the feet and bringing the lasting comfort needed to keep up with work environments.

The durability of work footwear is affected by the individual components that make up the structure. So let’s now discover the features contributing to work shoes and boots’ overall durability.

Table of Contents

Outsole

The outsole serves as the base of work boots or shoes.

High-quality outsoles provide support and stability to prevent slipping, and they also form an outer layer of defense against damage from the bottom of the footwear.

Thick outsoles made from rubber and other materials are stronger than thinner structures. They’re typically fitted into work boots and shoes, delivering superior strength and longevity in different work settings.

TPU outsoles are used in high-performance footwear (such as the Redback Bobcat Chelsea Boot) for challenging conditions because of their resistance to abrasion, chemicals, and oil.

Meanwhile, PU outsoles are flexible and are more resistant to damage caused by frequent flexing (due to walking).

Outsoles are often the first sections of footwear to show signs of damage, but the ones made with durable materials and designs can outlast lower-quality options.

Insole

Insoles keep the feet comfortable with sufficient padding, but they also ensure work footwear’s overall durability.

High-quality insoles deliver reliable arch support using materials designed to resist premature damage even with frequent or heavy use.

They also don’t need to be thick and bulky to provide the required cushioning and durability.

For example, OrthoLite insoles (such as the one in the Clarks Vargo Plain Oxford) offer breathability and cushioning in a low-profile structure which is also designed to resist compression for a long period significantly.

Meanwhile, latex foam insoles (including the one inside the Rockport Channer Oxford) offer firm support, breathability, and long-lasting performance.

Stitching

Stitching details can boost the style of work boots and shoes, but they also have functional benefits.

Strong, uniform, neat stitching throughout the footwear results in a clean look while reinforcing the bond of each component to one another.

This increases the overall durability of the boots and shoes, with the stitching securing the sections and preventing the footwear from falling apart even with heavy use.

The stitching design affects the overall durability of work footwear, but it’s worth noting that thread types also play a role in strengthening the structures.

For example, the Iron Age Groundbreaker Steel-Toe Boot features stitching using Kevlar thread – widely recognized for its outstanding abrasion resistance and strength that’s two times stronger compared to threads made of polyester or nylon.

Other enhancements, such as triple-stitched seams – as seen in the Caterpillar Holton Steel Toe Boot – ensure increased resistance against damage in the long run.

Upper Materials

The type of materials used for the uppers greatly impacts the durability of work footwear.

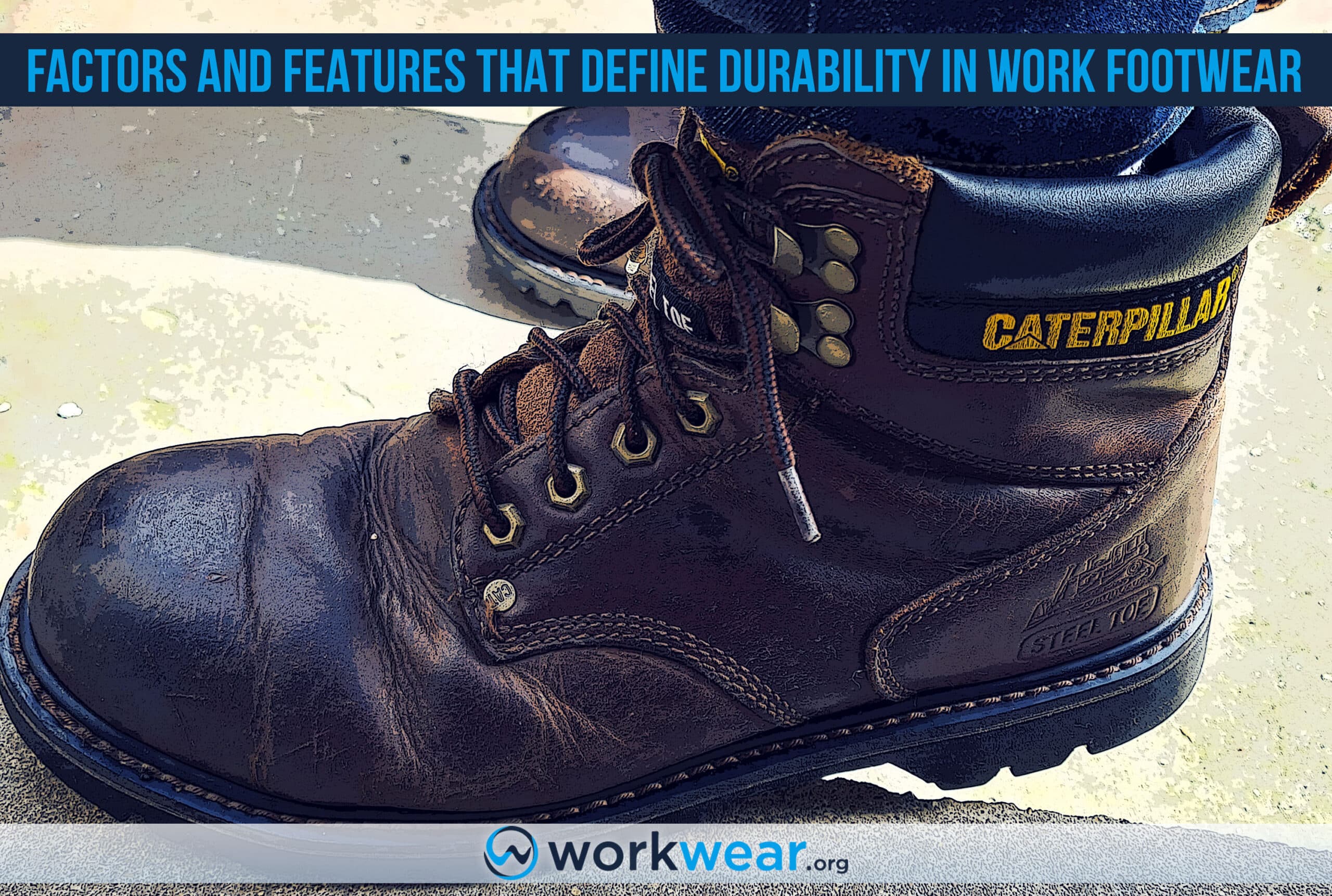

Rugged materials (such as the thick, full-grain leather of Caterpillar Second Shift Steel Toe Work Boots) offer more protection against safety threats and withstand the usual wear and tear much better than thinner materials (such as synthetic mesh).

These tough materials typically maintain their appearance and performance even after exposure to abrasion and other objects that can cause damage to the uppers’ structure.

High-quality leather also prevents moisture from seeping in, so the footwear’s interior is further protected against damage caused by unwanted wetness.

Laces

Shoelaces make it easier to adjust the footwear’s fit, and it helps if they’re also durable. However, they take a beating with the repeated tying, knotting, and loosening that need to be done for fit adjustments, with the ones made of high-quality materials expected to last much longer.

Laces made of strong materials (such as hard-wearing nylon and Kevlar) are better at resisting fraying even with heavy use compared to softer materials like waxed cotton.

The ones with rounded structures (such as the ones used in Puma Safety Conquest Composite Toe Boots) look like the ones fitted onto hiking boot shoelaces and are typically more durable than flat designs.

Hardware

The hardware in work boots typically refers to the eyelets and hooks, which are part of the lacing system. These sections are where the laces go through, and they need to be strong enough to withstand the constant movement and friction resulting from numerous lace adjustments.

Metallic hardware – featured in the Ariat Conquest 8-Inch Gore-Tex Hunting Boot – doesn’t easily break with heavy use and is expected to last long.

On the other hand, plastic lace hooks and eyelets are more prone to breakage, so they can’t be expected to remain as durable as metallic components.

Heel or Toe Overlays

Aside from using strong materials in the upper, work footwear can also be strengthened further with enhancements in strategic sections.

The heel and toe areas are most susceptible to abrasion and other types of damage, so reinforcing these points can greatly improve the work boots or shoes’ durability.

Thick materials made of rubber can be used over the heel or toe areas (such as the ones fitted into the Caterpillar Excavator LT Composite Toe Boot), making them stronger and more resistant to damage.

The extra material layer can also work for additional foot protection against dangerous impacts in the workplace.

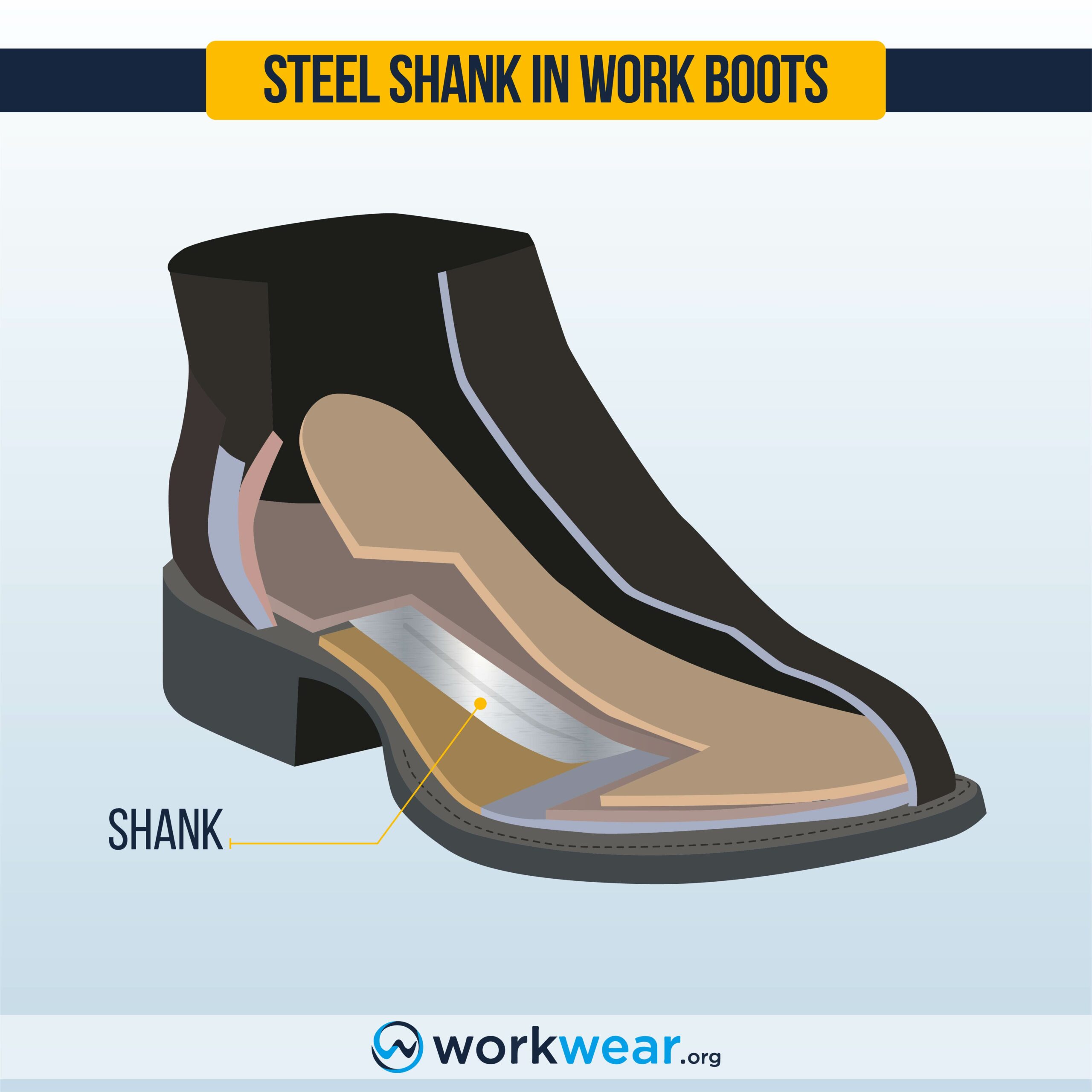

Shank

A shank is a narrow component (made of metal or non-metal materials) fitted into the boot, between the outsole and insole.

It provides the rigidity needed to maintain stability while walking in variable surface conditions and helps preserve the boot’s structural strength for a long time.

A steel shank, incorporated into the Chippewa Aldarion Boot, helps with durability by preventing the sole from sagging under the pressure of carrying the body’s weight for long hours.

Construction Method

The construction method used significantly affects work boots and shoes’ overall durability. Each method can dictate how the footwear performs and its ability to protect the foot against the elements and other threats.

For example, the Goodyear Welt construction method (featured in the Georgia Boot Hammer Internal Met Guard Steel Toe Work Boot) is known for improving footwear’s durability and resistance to water penetration.

Goodyear welted work boots and shoes are sturdy and stop liquids from being absorbed easily.

This construction method also allows the footwear to be re-soled so that the upper can still be maximized for a longer period, even after the outsole has worn away.

Personal Testing Experience

We had the opportunity to test two work footwear options with outstanding durability. The Timberland PRO 6-Inch Direct Attach Insulated Boot had a thick, waterproof leather upper that sealed out liquids in wet environments. It had metallic hardware and thick laces that didn’t break apart easily, even after heavy usage. Double and quadruple stitching details on the upper ensured the boot’s components stayed strongly bonded. The Thinsulate insulation preserved much-needed heat for superior foot comfort in cold conditions, while the Anti-Fatigue technology absorbed most of the shock of walking all day. However, the boot didn’t have safety toes and wasn’t suitable for hazardous worksites. Meanwhile, the Skechers Work Synergy – Sandlot Alloy Toe Work Shoe had a thick outsole with a height boost and excellent traction for improved walking stability, even over tricky surfaces. Thick laces withstood numerous fit changes without easily fraying or breaking apart. The memory foam insole worked with the exclusive FlexSole midsole to deliver generous cushioning and shock absorption. The boot’s alloy toe caps guarded the toes against dangerous compression and impact but didn’t feel as heavy as steel toes. The electrical hazard protection significantly reduced the risk of electric shock with exposure to open circuits in dry conditions. However, this isn’t a waterproof boot, making it unsuitable for wet environments.

Conclusion

Durable work shoes and boots perform better over the long run, providing the high-performance benefits required in various work scenarios. A footwear’s durability is defined by individual components that work together, strengthening the entire structure to become more resilient against abrasion and other forms of damage on the job. These features can be relied on to enhance the footwear’s strength, enabling it to function as expected even in challenging conditions, while resisting the most common signs of premature damage.

FAQs

- Are steel toe boots more durable than composite toe boots?

- It depends. The footwear’s durability is affected by different features – such as the materials and construction for the uppers and outsoles – and not necessarily by the material used for its safety toe caps.

- Do all durable work boots have toe or heel overlays?

- Not necessarily. For example, the Keen San Jose 6-Inch Boot is exceptionally durable but doesn’t come with overlays on the heel and toe areas.

- Why are plastic eyelets and hooks used in boots instead of metal if they’re less durable?

- Plastic eyelets weigh less than metallic components. Manufacturers may opt to use plastic lace hooks and eyelets to minimize the boots or shoes’ weight, so they won’t feel as bulky and are more comfortable to use over long periods.

- Are thick insoles more durable than thin ones?

- Not always. OrthoLite insoles are known for their thinness, but they’re designed to last long, with the material resisting lasting compression better than other foams.