Slip Resistant Boots vs Oil Resistant Work Boots

The workplace isn’t always the safest place for certain jobs. In addition, the surrounding area can have items that pose safety risks, especially if they’re not properly secured or cleaned after use. Some job sites may not be possible to avoid these threats even with the necessary preparations. However, the risk of injuries can be significantly reduced with the help of proper protective gear, such as footwear that strongly grips the ground to prevent slipping accidents.

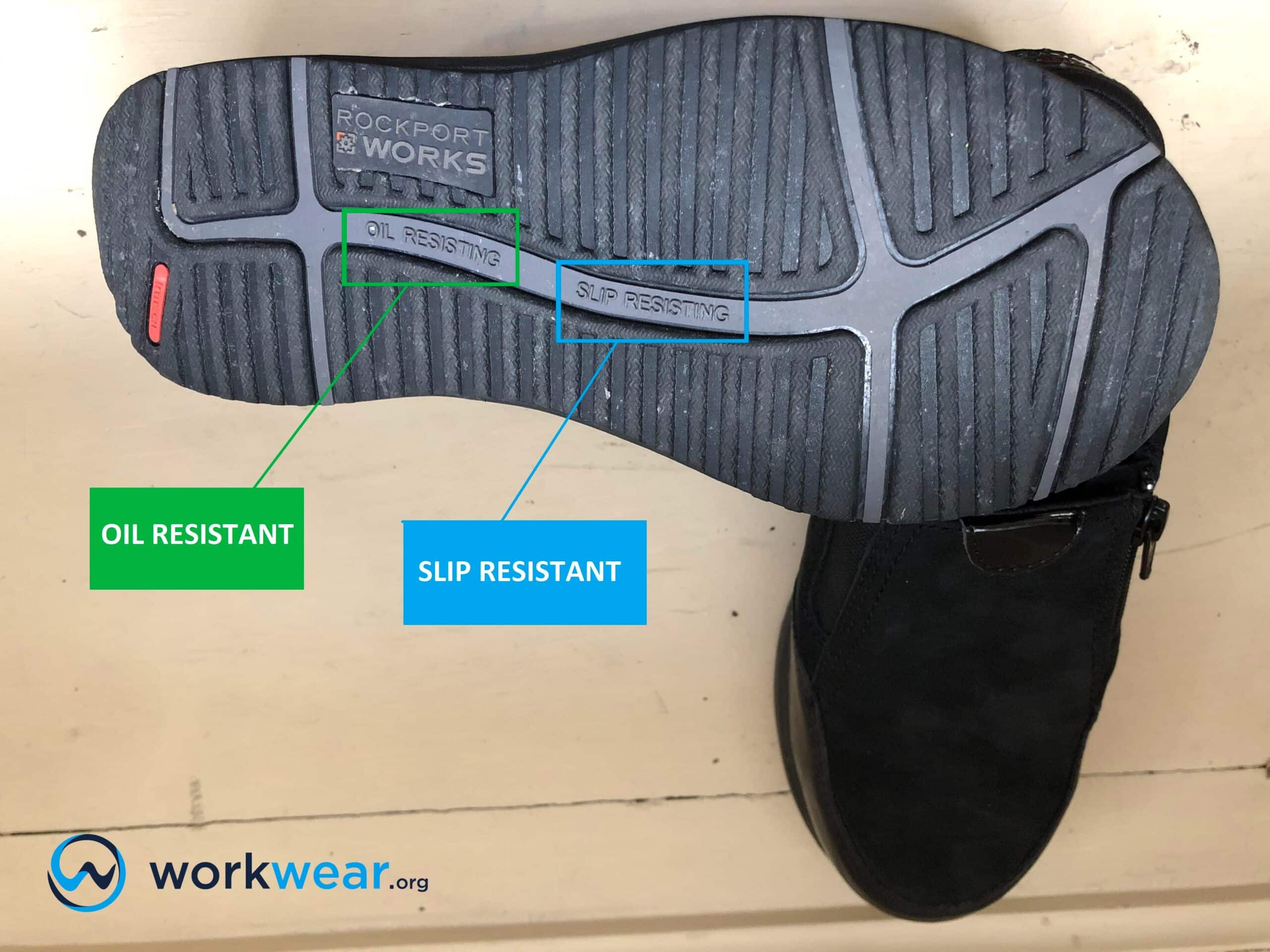

Work boots and boots that are slip-resistant and oil-resistant are essential for professionals whose work involves walking or moving around challenging surfaces. While it’s easy to use the terms interchangeably, slip-resistant boots are not the same as oil-resistant boots. It’s important to know the distinction between these two terms as they can bring benefits to different worksites and activities. It’s also worth noting that work footwear options can be slip-resistant and oil resistant. We’ll have a more detailed discussion below about each option’s strong points and potential drawbacks to better help you choose the one that fits your needs in the workplace.

Slip-Resistant Boots

Slip-resistant boots are constructed with soles that aim to prevent slipping on tricky surfaces. The slip resistance quality refers to the outsole that grips floors and other surfaces more efficiently than sole structures. These soles’ grip is strong enough to greatly minimize the risk of the wearer slipping or losing secure footing when moving over slippery or unstable ground conditions. Most, if not all, slip-resistant boots’ soles are made with special rubber compounds and have treads that work to increase stability while navigating extremely wet and slippery surfaces.

Key Advantages of Slip-Resistant Boots

Promotes confident, comfortable walking

Slip-resistant boots feature soles that deliver a high level of friction on the surfaces they come in contact with. The friction allows the sole to bite more firmly into the ground, making it easier to maintain a secure footing over various surface conditions without compromising safety. In addition, these boots help keep the feet planted more firmly into the ground, making it easier to walk efficiently over slick surfaces. With such a strong grip on floors and other surfaces, slip-resistant work boots can make the wearer feel more confident to walk over tricky surfaces without fearing that doing so would result in slipping or falling.

Significantly minimizes slipping risks on tricky surfaces

Slip-resistant boots are ideal for jobs that involve walking on floors and other surfaces that are often wet, slippery, or greasy. The soles grip the ground more efficiently than those that offer minimal or zero slip resistance, so these boots help considerably reduce the risks of slipping or falling to the ground when walking in challenging ground conditions.

Stronger traction on conventional surfaces

Slip-resistant boots have a better grip on conventional surfaces – such as asphalt or concrete – than oil-resistant boots (unless the oil-resistant boots also have slip-resistant features). Even if oil-resistant boots are often waterproof, they don’t have the powerful traction delivered by slip-resistant boots, which is needed to keep the footing stable on non-oily ground conditions.

Offer more versatile use

Boots with slip-resistant soles are useful on a wide range of surfaces as they offer a strong grip, making it easier to maintain stable footing in different ground conditions. These boots offer the same level of grip on various non-oily surfaces, so transitioning from one type of surface to another won’t be a problem since the soles will feel just as grippy. They can even work in varying weather conditions, especially if they have waterproof uppers.

Can help prevent foot fatigue

Slip-resistant work boots keep the feet planted firmly on the ground. This reduces the strain the feet and leg muscles feel as they try to keep the movements stable over slippery surfaces. In addition, with the soles of the boots powerfully gripping the ground, the feet can avoid feeling fatigued as they can move more naturally (and effortlessly) even while walking on slick floors and other surfaces.

Offer increased support for those with balance issues

The strong traction of slip-resistant boots delivers increased support for workers who already have problems maintaining a balanced gait. These boots help make steps more stable, so those who may experience difficulties with balance can take advantage of the added support, especially when walking on slick ground conditions.

May also offer oil resistance

It’s possible for slip-resistant boots also to have oil-resistant features. Work boots with both qualities deliver even more benefits, as they can be used in a wider variety of ground conditions where stable footing can otherwise be easily compromised.

Typically, more affordable than oil-resistant boots

Slip-resistant work boots often have a lower price range than oil-resistant boots, which usually have their entire structure enhanced to resist oil and chemicals. Boots with slip-resistant soles are generally more readily available and easier to find than oil-resistant ones, with more brands offering footwear choices at competitive prices.

Can secure footing in elevated work areas

Slip-resistant boots are suitable for working on elevated areas, such as platforms or ladders, where slipping can result in grave injuries or even death. The high-traction soles grip the floor or ladder rungs firmly, securing the feet so they won’t easily slip while moving up and down the elevated positions to get the job done.

Key Disadvantages of Slip-Resistant Boots

Can easily degrade when exposed to oil or chemicals

Work boots with slip-resistant soles are not suitable for walking on surfaces with chemicals or oils – unless they’re oil-resistant. This is because the soles and other parts of the boots can easily be damaged when exposed to harsh substances that may be present in tough work settings, especially if the boots’ components aren’t enhanced with oil-resisting qualities.

It may not prevent slipping on floors with chemicals or oils

Oils and other harsh substances (such as gasoline and chemicals) can make surfaces extremely slippery. Walking on these surfaces can be dangerous if the boots’ soles aren’t made with oil-resistant materials, with the soles having an increased risk of slipping and becoming damaged when exposed to acidic substances.

Uses of Slip-Resistant Boots

Slip-resistant boots are ideal for environments that are exposed to wet or slick floors, such as the workplaces of these professionals:

- Nurses

- Doctors

- Chefs and kitchen staff

- Food processing personnel

Oil-Resistant Boots

When it comes to oil-resistant boots, the resistance is often not confined only to the sole. Usually, these boots also have uppers resistant to oils and chemicals, including motor oils, gasoline, and solvents. In addition, these boots may be built with upper and sole materials that are enhanced to resist the absorption of chemicals and oils, protecting them from severe deterioration with constant exposure to harsh substances in demanding work environments.

Key Advantages of Oil-Resistant Boots

Generally, oil resistant for the entire shoe

In general, oil-resistant boots provide protection from the bottom and all around the entire footwear. While oil-resistant work boots only have the soles enhanced for this purpose, most of these shoe options are built with uppers and soles that resist damage when exposed to harsh chemicals and oils. This means that the whole shoe is enhanced to protect against acidic substances that can otherwise cause serious damage to the components.

Prevents slipping on surfaces with chemicals or oils

Oil-resistant boots are designed to deliver a strong grip on slippery or oily floors and other surfaces where chemicals may have spilled. They prevent slipping accidents and serious injuries that can otherwise happen when walking over these tricky surfaces, which may be difficult to avoid in certain job sites.

Often waterproof

The oil-resistant materials used for these work boots are often waterproof as well. This quality provides an extra layer of protection against the elements and liquids, keeping the feet dry even with long hours of exposure to sources of moisture while working outdoors and in other wet environments.

Prevents lasting damage when exposed to oils and chemicals

The materials of oil-resistant boots don’t absorb oil and chemicals, so that these agents won’t cause significant deterioration to the boots’ function and appearance. In addition, these boots are typically coated with a protective layer that prevents oil and harsh chemicals from seeping through, enabling them to preserve their quality and aesthetics even with exposure to strong substances that can otherwise penetrate boots without oil-resistant materials.

Protect the skin of the feet to avoid contact with harsh substances

Oil-resistant boots stop chemicals and oils from penetrating. This ensures that the harsh substances won’t have a chance to come into contact with the skin, preventing irritation and chemical burns that can cause serious harm when working around these potentially harmful agents in the work area.

Key Disadvantages of Oil-Resistant Boots

Less traction on conventional (non-oily) surfaces

Oil-resistant boots are designed to prevent sipping and material deterioration when walking on oily surfaces and those with chemicals. However, there are more suitable choices for extremely slippery surfaces that don’t have chemicals or oil, such as concrete. The soles of these boots often don’t deliver the exceptionally strong traction that slip-resistant soles do.

Generally, more expensive than slip-resistant boots

Work boots with oil-resistant boots often come with other safety enhancements for added protection in hazardous settings. These enhancements result in the boots having price points significantly higher than other slip-resistant boots with simpler features and fewer safety features.

More difficult to find compared to slip-resistant boots

Oil-resistant boots are less common than slip-resistant options, so they’re a bit more difficult to find. Footwear brands carry more slip-resistant shoe and boot options, so there are plenty of these to choose from, compared to oil-resistant boots that more prominent brands often offer.

Uses of Oil-Resistant Boots

Oil-resistant boots are suitable for professions that involve frequent exposure to oils, fuel, and other harsh chemicals, including:

- Chemical/industrial plant workers

- Auto mechanics

- Oil refinery personnel

- Farmers

Slip Resistant Boots vs Oil Resistant Work Boots – Comparison

| Boot Type |

Pros |

Cons |

|---|---|---|

| Slip-Resistant Boots |

|

|

| Oil-Resistant Boots |

|

|

Personal Testing and Experience

Demanding jobs usually require both strong slip resistance and resistance to oil and chemicals – and high-quality work boots are mostly both oil- and slip-resistant. We had the chance to test some of the top oil- and slip-resistant work boots, with the Timberland PRO Pit Boss Steel Toe Work Boot standing out with both of these qualities but with other safety features (such as safety toe caps and electrical hazard protection) as well. It’s also worth noting that you don’t have to spend a fortune to be able to enjoy the benefits of slip- and oil-resistant boots. For instance, the Skechers Work Workshire Steel Toe Boot has both features but is still reasonably priced below $100. In addition, most slip-resistant boots and oil-resistant boots have streamlined, almost sporty profiles that offer comfort and convenience while preventing slipping accidents in the work area.

Conclusion

Slip-resistant and oil-resistant boots promote stable walking experiences with their strong traction, but each option offers a unique set of benefits worth examining. Work boots with slip-resistant soles promote confidence with comfortable stability, minimize slipping threats on tricky (non-oily) surfaces, can improve the secure footing of those with balance issues, and may help fight foot fatigue. They’re also more versatile, can offer oil resistance, secure the feet on elevated work areas, and are more affordable than oil-resistant boots. On the other hand, oil-resistant boots often showcase that specific resistance all over the shoe (not just on the sole) and prevent slipping and material deterioration when exposed to oils and chemicals. In addition, they’re often waterproof and protect the skin of the feet so they won’t get irritated by acidic substances. Going for the choice that suits the specific worksite requirements will ensure not only improved safety against slipping but full optimization of the work boots’ remarkable qualities.

FAQs

- Are slip-resistant boots better than oil-resistant boots?

- Not always. In ordinary work sites that aren’t exposed to hazardous substances, slip-resistant boots are more than enough to promote improved stability while standing and walking around. However, oil-resistant boots may be better for jobs with significant exposure to oils and chemicals. This is because they deliver strong traction while protecting the footwear and the feet against the harmful effects of harsh substances.

- Do oil-resistant boots always feel heavy?

- Not always. There are oil-resistant boots that are quite lightweight, such as those that are constructed using leather with nylon panels to keep the weight reduced as well as to improve breathability and comfort.

- What materials are used for oil-resistant soles?

- The most common material used for oil-resistant soles is rubber because of its strong resistance to abrasive materials and oil. Other materials include EVA, known for its cushioning and stability for superior comfort, and TPU, which delivers remarkable durability without unwelcome heaviness.

- Are slip-resistant boots necessary for all job sites?

- It depends on the nature of the job and work conditions. Office jobs in indoor settings don’t need boots with high-traction soles, especially if the workers will only go to areas with slippery surfaces. On the other hand, slip-resistant boots are required for professionals who work on low-traction surfaces, such as kitchen floors or hospital floors that are always wet or prone to liquid spills.